In my last two posts I showed you fixed location storage and its disadvantages, random chaotic, and ABC storage. But there is more. Another option is some sort of combination of fixed location, random chaotic, and ABC storage. Let’s look at some of the variants.

In my last two posts I showed you fixed location storage and its disadvantages, random chaotic, and ABC storage. But there is more. Another option is some sort of combination of fixed location, random chaotic, and ABC storage. Let’s look at some of the variants.

Material Flow

Storage Strategies – Random Chaotic and ABC

In my last post I looked at the disadvantages of fixed location storage. Usually much better is random chaotic storage. This is, for example, the preferred method of Amazon. This approach makes best use of the available space and generates less mistakes. When Amazon started using this, they reportedly were able to store twice as many items in the same space as as before.

In my last post I looked at the disadvantages of fixed location storage. Usually much better is random chaotic storage. This is, for example, the preferred method of Amazon. This approach makes best use of the available space and generates less mistakes. When Amazon started using this, they reportedly were able to store twice as many items in the same space as as before.

Storage Strategies – Fixed Location

In my last post I looked at different ways to store material. This post is a continuation, looking at where to put materials. I want to give an overview of the different options to help you choose one that is suitable for your situation. This first post looks at storage with fixed locations, and why this is usually not so hot.

In my last post I looked at different ways to store material. This post is a continuation, looking at where to put materials. I want to give an overview of the different options to help you choose one that is suitable for your situation. This first post looks at storage with fixed locations, and why this is usually not so hot.

Storage Strategies – Even More Stacking Options

There are even more storage options. Continuing from my last post, I will show you some more options to store your material. This post is with much thanks to Juan Carlos Viela for the detailed suggestions!

There are even more storage options. Continuing from my last post, I will show you some more options to store your material. This post is with much thanks to Juan Carlos Viela for the detailed suggestions!

Storage Strategies – Stacking Options

If you are in production, you have material. You probably have too much, except for the one thing that’s missing. In this blog post I will give an overview of the options for storing material. Hopefully this will give some inspiration. Please note that this is not on how to manage the material, merely on how to store it. This is the start of a small series on how to store material.

If you are in production, you have material. You probably have too much, except for the one thing that’s missing. In this blog post I will give an overview of the options for storing material. Hopefully this will give some inspiration. Please note that this is not on how to manage the material, merely on how to store it. This is the start of a small series on how to store material.

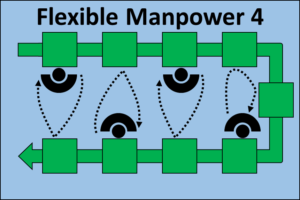

Flexible Manpower Lines 4 – How-To do Flexible Manpower Lines

This is the final post in this series on flexible manpower lines. Since we completed the example line in the last post, I will give you a brief theoretical run-down on how to divide the work among multiple people. I will also show you some easier-to-manage but maybe not-quite-as-efficient alternative options, the bucket brigade and the rabbit chase.

This is the final post in this series on flexible manpower lines. Since we completed the example line in the last post, I will give you a brief theoretical run-down on how to divide the work among multiple people. I will also show you some easier-to-manage but maybe not-quite-as-efficient alternative options, the bucket brigade and the rabbit chase.

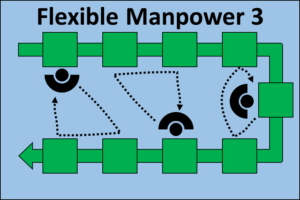

Flexible Manpower Lines 3 – Example Line

This third post in the series continues with the example on flexible manpower lines. Now we will investigate different options for these flexible manpower lines (also called Shoujinka 少人化). I will show you the details on all options between a single operator and the (sensible) maximum of six operators, and why for our example it does not make sense to use four or five operators.

This third post in the series continues with the example on flexible manpower lines. Now we will investigate different options for these flexible manpower lines (also called Shoujinka 少人化). I will show you the details on all options between a single operator and the (sensible) maximum of six operators, and why for our example it does not make sense to use four or five operators.

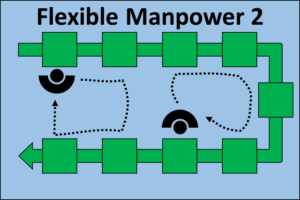

Flexible Manpower Lines 2 – Alternatives and Example

Having a flexible manpower line is a good way to adjust the production capacity to changing demand while still keeping your system leveled. In this second post in my series on flexible manpower lines, I give you some alternatives before going into more details of an example line that we will set up for different numbers of operators in the next few posts.

Having a flexible manpower line is a good way to adjust the production capacity to changing demand while still keeping your system leveled. In this second post in my series on flexible manpower lines, I give you some alternatives before going into more details of an example line that we will set up for different numbers of operators in the next few posts.