Standards are one of the backbones of lean manufacturing. For a standard to be good and used consistently, it should be self-explanatory. Additionally, you should understand it well enough to easily recognize deviations from the standard. I would like to give you an example of how my thought process works when exploring a standard.

Standards are one of the backbones of lean manufacturing. For a standard to be good and used consistently, it should be self-explanatory. Additionally, you should understand it well enough to easily recognize deviations from the standard. I would like to give you an example of how my thought process works when exploring a standard.

Pull

Different Ways to Establish a Pull System – Part 2

This is the second post on different types of pull production. It features the less commonly known approaches of triangle kanban, drum-buffer-rope, reorder point (surprise, yes, it is a pull system), reorder period (also a pull system), and FIFO lanes. In my previous post I showed you the kanban system and its variant, the two-bin system, as well as CONWIP and the kanban-CONWIP hybrid.

This is the second post on different types of pull production. It features the less commonly known approaches of triangle kanban, drum-buffer-rope, reorder point (surprise, yes, it is a pull system), reorder period (also a pull system), and FIFO lanes. In my previous post I showed you the kanban system and its variant, the two-bin system, as well as CONWIP and the kanban-CONWIP hybrid.

Different Ways to Establish a Pull System – Part 1

Pull production is one of the most important aspects of lean production. Its key feature is to have an upper limit on inventory that is not to be exceeded. The most well-known way to implement a pull system is by using kanban cards. However, there are many others. In this short series of two posts, I want to give you an overview of the different ways to implement pull systems, and discuss the pros and cons of them.

Pull production is one of the most important aspects of lean production. Its key feature is to have an upper limit on inventory that is not to be exceeded. The most well-known way to implement a pull system is by using kanban cards. However, there are many others. In this short series of two posts, I want to give you an overview of the different ways to implement pull systems, and discuss the pros and cons of them.

How to Ramp Up a Kanban System – Part 2: The Switch

In my last post I described how to prepare for the implementation of a kanban system. This post goes into more detail on the actual change to the new kanban system. You surely know that every part should have a kanban. But what do you do if you have more kanban than parts? What do you do if you have more parts than kanbans? Find the answers below.

In my last post I described how to prepare for the implementation of a kanban system. This post goes into more detail on the actual change to the new kanban system. You surely know that every part should have a kanban. But what do you do if you have more kanban than parts? What do you do if you have more parts than kanbans? Find the answers below.

How to Ramp Up a Kanban System – Part 1: Preparation

Designing a kanban system on paper is much easier than implementing it on the shop floor. In many of my previous posts I discussed the design of a kanban system in detail. In these two posts I will discuss the steps needed to actually put the system on the ground. This first post is the preparation, and my next post will be the actual switch to the new kanban system.

Designing a kanban system on paper is much easier than implementing it on the shop floor. In many of my previous posts I discussed the design of a kanban system in detail. In these two posts I will discuss the steps needed to actually put the system on the ground. This first post is the preparation, and my next post will be the actual switch to the new kanban system.

Kanban Card Design

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

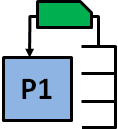

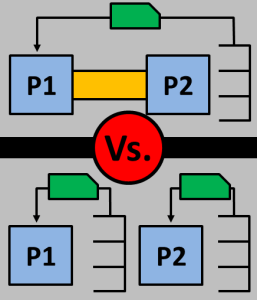

Supermarket vs. FiFo – What Requires Less Inventory?

To create pull production between two processes, you can add either a FiFo lane or a supermarket. In one case you will have the FiFo as part of a bigger kanban or CONWIP loop, and in the other case you split the value stream into two different kanban or CONWIP loops.

To create pull production between two processes, you can add either a FiFo lane or a supermarket. In one case you will have the FiFo as part of a bigger kanban or CONWIP loop, and in the other case you split the value stream into two different kanban or CONWIP loops.

Some questions that I have been pondering are: Which one has less inventory for the same delivery performance? Is it better to use a big loop or two smaller loops for the WIP and delivery performance trade off?