Toyota did not start out as a lean company, but evolved over time. This was also not an automatic process. It needed a lot of care and attention, as well as continuous improvement and PDCA. This is the second post of this short, two-post series on the path of Toyota from a messy and hard-to-manage job shop to a much more efficient flow shop.

Toyota did not start out as a lean company, but evolved over time. This was also not an automatic process. It needed a lot of care and attention, as well as continuous improvement and PDCA. This is the second post of this short, two-post series on the path of Toyota from a messy and hard-to-manage job shop to a much more efficient flow shop.

Highly Suggested Features for Multi-Machine Handling

One person per machine is easy. One person for multiple machines is a bit more difficult. Now the worker has multiple responsibilities. This requires better training, as the worker must be qualified on all processes he is taking care of. It is also a bit more of a balancing act. One feature that greatly simplifies this approach is to have the machine stop automatically. It is no problem if the machine waits for the worker to start the process. There is no harm to the product if it sits idle in front of the machine. However, it is a much larger problem if the machine waits for the worker to STOP the process. If the worker is delayed, the product may be damaged or completely ruined.

Just imagine making roast beef. If the beef sits in the fridge, a one-hour delay does not hurt the beef. If the beef is in the oven, a one-hour delay is the difference between a nice meal and the charred remains of former food. Hopefully, it does not burn your kitchen down, either.

Just imagine making roast beef. If the beef sits in the fridge, a one-hour delay does not hurt the beef. If the beef is in the oven, a one-hour delay is the difference between a nice meal and the charred remains of former food. Hopefully, it does not burn your kitchen down, either.

The work is also greatly simplified if the worker does not have to come back to the machine during one operation. If the worker has to come back to change a tool, or to set up the part for milling from a different side, or any other task during the processing of one part, this greatly complicates the work sequence for the worker. If possible, automate these intermediate steps as much as possible.

Arrangement in Process Order

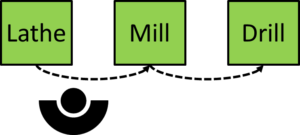

One flaw that Toyota observed with this setup of one person handling multiple similar machines was a pile-up of completed goods. This multi-machine handling improved efficiency, but the system was not yet set up to handle these larger quantities of finished or semi-finished goods. In lean terms, there was no flow. The material was sitting around instead of moving to the next location.

A possible solution would be to beef up logistics for a faster material handling… but Toyota found a much better solution: it arranged the processes in the order of which the parts were processed. Instead of one operator handling two or three lathes, another another or three drills, and another two or three milling machines, they had one operator handle the entire sequence. They changed their job shop into a flow shop, or at least into work cells.

A possible solution would be to beef up logistics for a faster material handling… but Toyota found a much better solution: it arranged the processes in the order of which the parts were processed. Instead of one operator handling two or three lathes, another another or three drills, and another two or three milling machines, they had one operator handle the entire sequence. They changed their job shop into a flow shop, or at least into work cells.

This had significant benefits. The handling of the material was much reduced. Originally the worker was taking the part out of the machine for logistics to bring it elsewhere (next process? warehouse?…) so another worker could put the part back into the machine. Now, the worker removed the part from a machine and added it right into the next machine. Excess handling and transport was significantly reduced. The piles of material between the different machines disappeared almost completely. Lead time was reduced, cost was reduced, and the process became much more … lean. Instead of the shop floor looking like small isolated islands with little connection to each other, it became a basic flow shop.

Since the worker was in charge of a sequence of processes, this also almost accidentally improved the quality. Any problem caused by one process for a subsequent process was noticed right away, and was noticed by the same worker. This shorter feedback loop made it much easier to improve quality.

Arrangement in Flow

Finally, Toyota arranged these processes in a line. This had the drawback of increasing the walking distance of the worker slightly. However, it solved another problem for Toyota: the overall target for the speed was based on the customer takt. However, it was difficult to set up the processes so the workload for one worker was exactly one customer takt (adjusted for the losses, i.e., adjusted using the OEE). They had many work cells where they needed fewer than one worker to match the customer takt.

Finally, Toyota arranged these processes in a line. This had the drawback of increasing the walking distance of the worker slightly. However, it solved another problem for Toyota: the overall target for the speed was based on the customer takt. However, it was difficult to set up the processes so the workload for one worker was exactly one customer takt (adjusted for the losses, i.e., adjusted using the OEE). They had many work cells where they needed fewer than one worker to match the customer takt.

For example, if a cell needs only 0.4 workers to match the takt, then you have to round up. (Note there are some exceptions where you can have a worker shift between cells, but this is tricky and also often wasteful.) You need 0.4 workers, but you have to place 1.0 workers in the cell. You waste 60% of the time of one worker. In longer lines where the processes are arranged linear (or U-shaped), you can have multiple workers in the same system. This makes it much easier to have a consistent workload for each worker, with the leftover free time usually pooled at the last worker.

In fact, many different ways of setting up the workers are possible, where you can adjust the number of workers to the customer demand. If the customer has a higher demand (a faster takt), you add workers into the system; if the demand goes down again (a slower takt), you remove workers again. Possible approaches are chaku-chaku lines, bucket brigades, rabbit chases, or one-up-one-down approaches.

This was roughly the evolution of Toyota from a very inefficient job shop to a much more efficient flow shop. Sure, you could optimize the job shop, but if you do not make the transition to a flow line, you will miss out on a lot of improvement potential.

These two posts gave a quick review of the evolution steps at Toyota from a messy job shop to a much better flow shop. However, the evolution does not stop here, and Toyota always continues to improve. It also was not necessarily a straight road, and Toyota tried some different approaches that did not turn out well and were reversed. I hope your company is also able to continuously improve, even if not every try is a success. Now, go out, evolve your company, and organize your industry!

Source

Toyota Motor Corporation. 1973. Toyota Production System Handbook, Appendix. Translated by Mark Warren.