In my last post of this series on the changeover wheel and changeover sequencing, I showed you the basics on how to use a changeover wheel or changeover sequence. In this post I will look at a few options and modifications that are sometimes used too.

In my last post of this series on the changeover wheel and changeover sequencing, I showed you the basics on how to use a changeover wheel or changeover sequence. In this post I will look at a few options and modifications that are sometimes used too.

A Brief Recap

We will continue the example from the previous posts of an ice cream maker with three types of waffles, three flavors, and three sizes. This gives us a total of 27 different products. We created a changeover sequence (the changeover wheel) and added production jobs in sequence of priority.

Option: Adjust to Reduce Changeover Time

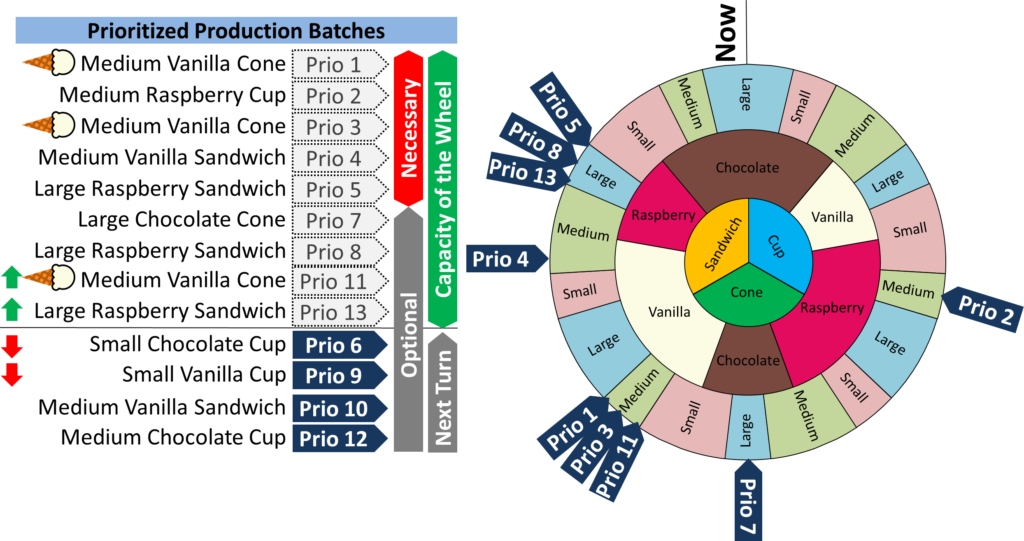

My recommended way is to fill the changeover wheel simply by priority of the jobs. However, there is also a modification possible. Out of all your possible and prioritized jobs, there are some that you must do during the next turn of the changeover wheel. These are necessary, and if you don’t do them you may run out of ice cream… and nobody wants that! However, there are other possible jobs that are less urgent, and you either could do them this turn or wait for the next turn. In the graph below I have labeled them “necessary” and “optional.”

Obviously, you must fit the necessary jobs in your wheel. (If you can’t, then you may have capacity issues, which is a different problem from the sequencing.) But among the other jobs, you may pick and choose which ones fit best in your sequence. In the example above, I have moved Prio 11 and Prio 13 up, since I am doing these product types anyway. To ensure I do not overload the capacity of the wheel, I moved jobs 6 and 9 down. Jobs 6 and 9 are optional, and I can do them this turn or during the next turn of the wheel. By doing them next turn, I save some changeover effort, since I go directly from raspberry sandwiches (jobs 5, 8, and 13) to raspberry cups (job 2) without ever having to switch the flavor to chocolate or vanilla. Much less wasted ice cream.

Obviously, you must fit the necessary jobs in your wheel. (If you can’t, then you may have capacity issues, which is a different problem from the sequencing.) But among the other jobs, you may pick and choose which ones fit best in your sequence. In the example above, I have moved Prio 11 and Prio 13 up, since I am doing these product types anyway. To ensure I do not overload the capacity of the wheel, I moved jobs 6 and 9 down. Jobs 6 and 9 are optional, and I can do them this turn or during the next turn of the wheel. By doing them next turn, I save some changeover effort, since I go directly from raspberry sandwiches (jobs 5, 8, and 13) to raspberry cups (job 2) without ever having to switch the flavor to chocolate or vanilla. Much less wasted ice cream.

But again, you can do this only if you are confident that you are not running out of the de-prioritized products. In effect, you accept a slightly smaller risk of a stock out for a reduction in changeover effort… AND quite a bit of management decision making! If you manually switch things around, you have to… well… manually switch things around. This can be quite a bit of effort, and also can be another potential source of mistakes. Especially for these reasons I usually avoid messing with the sequence besides the priority. But, if you want to do this, it can work.

Always Plan an Entire Changeover Wheel

The first point is a pitfall. You should always plan an entire changeover wheel or sequence! Do not plan only segments of the wheel. This is tied to the different parts of the wheel having different workloads. If you decide to fill jobs for only part of a wheel, as shown here, it will be tricky to decide how much capacity (jobs or production hours) to allocate for this part of the wheel. This is difficult.

The first point is a pitfall. You should always plan an entire changeover wheel or sequence! Do not plan only segments of the wheel. This is tied to the different parts of the wheel having different workloads. If you decide to fill jobs for only part of a wheel, as shown here, it will be tricky to decide how much capacity (jobs or production hours) to allocate for this part of the wheel. This is difficult.

You could eyeball it and say, “If my entire wheel is three hours of production, then each one-third segment should be 1 hour.” This sounds logical, but it is not! How do you know that the demand of the customer distributes evenly around the wheel? It could be that your first third are all slow runners, and you are wasting your precious capacity with jobs that you need only far in the future. When you finally get to the second or third segment with all the urgent high runners, you may lack the capacity to produce them. You produced a lot of goods that you need only much later, but you are now short on the products that you need soon. Hence, always plan an entire changeover wheel or changeover sequence! Never plan only part of a changeover wheel.

You could eyeball it and say, “If my entire wheel is three hours of production, then each one-third segment should be 1 hour.” This sounds logical, but it is not! How do you know that the demand of the customer distributes evenly around the wheel? It could be that your first third are all slow runners, and you are wasting your precious capacity with jobs that you need only far in the future. When you finally get to the second or third segment with all the urgent high runners, you may lack the capacity to produce them. You produced a lot of goods that you need only much later, but you are now short on the products that you need soon. Hence, always plan an entire changeover wheel or changeover sequence! Never plan only part of a changeover wheel.

On the other hand, you can without problem plan multiple wheels ahead of time. For example, if your wheel is 3 hours, and you have 15 working hours per day, you can without problem plan 5 changeover wheels in one go, and be done for the day. This may reduce planning effort and is also more flexible on the planners agenda, since they have to do it only once every five turns instead of planning every turn. On the other hand, it reduces your flexibility a bit, since changes in demand for the 2nd, 3rd, 4th, and 5th turn are not taken under consideration.

On the other hand, you can without problem plan multiple wheels ahead of time. For example, if your wheel is 3 hours, and you have 15 working hours per day, you can without problem plan 5 changeover wheels in one go, and be done for the day. This may reduce planning effort and is also more flexible on the planners agenda, since they have to do it only once every five turns instead of planning every turn. On the other hand, it reduces your flexibility a bit, since changes in demand for the 2nd, 3rd, 4th, and 5th turn are not taken under consideration.

Re-Planning

The more often you plan, the quicker you can adjust to changes in demand. But always plan an an entire changeover wheel! However, it is possible to plan more frequently than a turn of the wheel. This is illustrated here, where the managers re-plan for every change of the waffle type (i.e., they re-plan three times per turn of the wheel. But again, they MUST plan the entire wheel). They only choose to change the plan when they redo the planning. This is necessary to make sure the available capacity is indeed used for the most important products.

The more often you plan, the quicker you can adjust to changes in demand. But always plan an an entire changeover wheel! However, it is possible to plan more frequently than a turn of the wheel. This is illustrated here, where the managers re-plan for every change of the waffle type (i.e., they re-plan three times per turn of the wheel. But again, they MUST plan the entire wheel). They only choose to change the plan when they redo the planning. This is necessary to make sure the available capacity is indeed used for the most important products.

Of course, this is a lot of effort and management overhead. I see two possible situations where you can do that. First, if you have a sufficiently advanced ERP system that can do the planning automatically, then it is no sweat on your brow, you just let the computer worry about all the planning. Do this only if you have a high level of trust in your computer system. Actually, let me rephrase this: do this only if the people that are using the ERP system every day for planning have a high level of trust in your computer system!

The second reason to re-plan is probably more common. Something unexpected happened, the customer is yelling at your boss, your boss is yelling at you, and you need to change the production plan to make your boss and your customer happy (or at least less angry) ((or at the very least angry against somebody else…)). In this case, re-plan the entire changeover wheel (changeover sequence) to incorporate the latest information (the yelling). Discard the previous plan that has not yet been started.

As so often, what started as a one- or two-blog post series is getting quite lengthy when I start to go into the detail. And we are not yet done. In my next post I will look at more things that you can or should consider for the changeover wheel. Now, go out, fix your sequence to make your boss and your customer happy, and organize your industry!

P.S.: This blog post was inspired by a master thesis by my student Milena Oberle: “Entwicklung eines Steuerungskonzepts zur Stabilisierung volatiler Auftragsfolgen einer variantenreichen Mischfertigung unter Berücksichtigung der zukunftsweisenden Erfolgsfaktoren einer Smart Factory,” Hochschule Karlsruhe, 2022.

Overview of Blog Post Series

- A Few More Turns on the Changeover Wheel – Part 1: Creating a Sequence

- A Few More Turns on the Changeover Wheel – Part 2: Improving the Sequence

- A Few More Turns on the Changeover Wheel – Part 3: Prioritizing Jobs

- A Few More Turns on the Changeover Wheel – Part 4: Options for Prioritizing

- A Few More Turns on the Changeover Wheel – Part 5: Frequently Asked Questions

What a great article and final part to wrap up prioritizing jobs. The biggest takeaway that I have gotten from this is the key to planning prior to trying out the new system. Also, one must continuously look at their plan and edit it for further improvement. A quick way to help the system move smoothly would be making the cones in the morning and having the cups laid out, having you stocked and prepared for the afternoon/night rush. This would allow you to just have to focus on flavor and size variations. I feel that a re-plan is the most common way someone must plan, as we know the supply chain system as of late always has something new pop up.