This small series on Total Productive Maintenance (TPM) looks at the pillars of the TPM framework. This particular post focuses on the topic of autonomous maintenance, which I think is a valid and useful pillar of TPM. It is one of the pillars of the framework where TPM really shines and adds a lot of value to industry. Sometimes it is even listed as the first pillar to underline its importance for maintenance. The ideas of autonomous maintenance can be applied in almost any shop floor, improving the overall system performance and reducing the cost.

This small series on Total Productive Maintenance (TPM) looks at the pillars of the TPM framework. This particular post focuses on the topic of autonomous maintenance, which I think is a valid and useful pillar of TPM. It is one of the pillars of the framework where TPM really shines and adds a lot of value to industry. Sometimes it is even listed as the first pillar to underline its importance for maintenance. The ideas of autonomous maintenance can be applied in almost any shop floor, improving the overall system performance and reducing the cost.

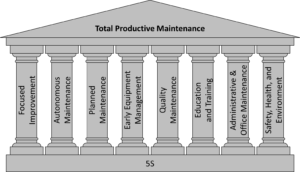

For a quick reference, here again are the eight pillars of TPM. The bold one is the focus of this blog post.

- Focused Improvement (meaning Continuous Improvement)

- Autonomous Maintenance

- Planned Maintenance

- Early Equipment Management (meaning Design for Maintenance)

- Quality Maintenance (which in lean would be called Jidoka)

- Education and Training (which in lean would be part of standardization)

- Administrative & Office Maintenance

- Safety, Health, and Environment

Overview of Autonomous Maintenance

The next pillar Autonomous Maintenance is a very important pillar. In Japanese this is called Jishu Hozen (自主 保全 for independence; autonomy; self-reliance and preservation; integrity; conservation; maintenance). The “total” in Total Productive Maintenance refers to involving everybody in the maintenance efforts. The idea in a nutshell is that the operators of the machine take over part of the maintenance. This is very sensible and useful. Nobody will know the machine as well as the worker who spends eight hours per day with it. Implementing autonomous maintenance often includes a time slot for every shift focused on maintenance.

The next pillar Autonomous Maintenance is a very important pillar. In Japanese this is called Jishu Hozen (自主 保全 for independence; autonomy; self-reliance and preservation; integrity; conservation; maintenance). The “total” in Total Productive Maintenance refers to involving everybody in the maintenance efforts. The idea in a nutshell is that the operators of the machine take over part of the maintenance. This is very sensible and useful. Nobody will know the machine as well as the worker who spends eight hours per day with it. Implementing autonomous maintenance often includes a time slot for every shift focused on maintenance.

How to Do Autonomous Maintenance

There are a few important aspects of autonomous maintenance. First, the worker is able to do simple maintenance tasks himself. This may include cleaning, lubrication, fixing minor errors, tightening nuts and bolts, and other simple tasks. It may also include safety checks. For computer controlled machines, it can also include taking care of smaller error messages or simply pressing a button to acknowledge a digital warning. It helps that normally 70%–80% of the work done by maintenance personnel does not require advanced technical skills. (Source: Baudin, Michel. Working with Machines: The Nuts and Bolts of Lean Operations with Jidoka. 1st ed. New York, USA: Productivity Press, 2007. ISBN 978-1-56327-329-2. Pg. 305)

There are a few important aspects of autonomous maintenance. First, the worker is able to do simple maintenance tasks himself. This may include cleaning, lubrication, fixing minor errors, tightening nuts and bolts, and other simple tasks. It may also include safety checks. For computer controlled machines, it can also include taking care of smaller error messages or simply pressing a button to acknowledge a digital warning. It helps that normally 70%–80% of the work done by maintenance personnel does not require advanced technical skills. (Source: Baudin, Michel. Working with Machines: The Nuts and Bolts of Lean Operations with Jidoka. 1st ed. New York, USA: Productivity Press, 2007. ISBN 978-1-56327-329-2. Pg. 305)

Second, the worker will be the first to notice changes in the machine behavior. He probably knows the machine better than anyone else, and is much more likely to notice an issue before it turns into a bigger problem. If he alerts maintenance about such an issue, it may be fixed before the machine breaks down. Examples could be unusual clanking sounds, the smell of something starting to heat up, or general unusual behavior of the system. They also have the responsibility to escalate if something seems odd.

Second, the worker will be the first to notice changes in the machine behavior. He probably knows the machine better than anyone else, and is much more likely to notice an issue before it turns into a bigger problem. If he alerts maintenance about such an issue, it may be fixed before the machine breaks down. Examples could be unusual clanking sounds, the smell of something starting to heat up, or general unusual behavior of the system. They also have the responsibility to escalate if something seems odd.

In autonomous maintenance, the worker is able to do smaller inspection tasks, like reading gauges, measuring pressures or tensions, and so on. This may also include some documentation. This also reduces the workload of the maintenance personnel and makes these inspections more efficient.

In autonomous maintenance, the worker is able to do smaller inspection tasks, like reading gauges, measuring pressures or tensions, and so on. This may also include some documentation. This also reduces the workload of the maintenance personnel and makes these inspections more efficient.

It is usually in the worker’s best interest to have a well-functioning machine. Hence, the worker may take better care of the machine than a far-away and rarely visiting maintenance guy. He is also already at the machine, hence there is no extra walking involved. For simple breakdowns, the fix may also be much faster than if the worker has to issue a maintenance request and wait for maintenance. The worker may also notice upcoming problems much earlier, whereas the maintenance guy may notice it only after it breaks. Overall, a lot of maintenance may be faster and cheaper than if a person from maintenance has to come to take care of the machine. Highly trained maintenance personnel may be freed up to take better care of the more complicated tasks. Increasing efficiency of maintenance and shifting tasks from higher trained and potentially higher paid maintenance personnel to machine operators also reduces labor cost.

It is usually in the worker’s best interest to have a well-functioning machine. Hence, the worker may take better care of the machine than a far-away and rarely visiting maintenance guy. He is also already at the machine, hence there is no extra walking involved. For simple breakdowns, the fix may also be much faster than if the worker has to issue a maintenance request and wait for maintenance. The worker may also notice upcoming problems much earlier, whereas the maintenance guy may notice it only after it breaks. Overall, a lot of maintenance may be faster and cheaper than if a person from maintenance has to come to take care of the machine. Highly trained maintenance personnel may be freed up to take better care of the more complicated tasks. Increasing efficiency of maintenance and shifting tasks from higher trained and potentially higher paid maintenance personnel to machine operators also reduces labor cost.

Giving the worker more control over his machine is a way to empower the employee and make him more involved. It gives the operator more “ownership” of the equipment. Not always, but often this helps with morale. Hence, there are usually lots of benefits in autonomous maintenance, often resulting in savings in maintenance cost as well as better machine performance and fewer breakdowns.

The Effort to Do Autonomous Maintenance

On the downside, the workload for the operator increases. It may be necessary to free up time for the worker to do maintenance. However, if done right, the additional workload of the operator will be less than the freed up time of the (sometimes more expensive) maintenance personnel. Nevertheless, since workload shifts from maintenance to production, expect some political wrangling of the involved stakeholders.

Additionally, you need to train the operators to do simple maintenance tasks. This can be done in a classroom, but hands-on training on site is usually better. Ideally, the worker should have a standard on how to do maintenance. This could be a list of which bolts to tighten and which places to lubricate when and how, what where and when to inspect, and so on. This may also include elements related to cleanliness (5S). Like any standard, someone also needs to occasionally check to make sure the standard is followed, and there should be a process on how to improve the standard. This training and the resulting standard should also include steps to alert maintenance personnel if the worker notices something out of the ordinary. The current state could also be part of the shop floor meeting or shift handover. There could also be documentation on the performed maintenance steps.

Additionally, you need to train the operators to do simple maintenance tasks. This can be done in a classroom, but hands-on training on site is usually better. Ideally, the worker should have a standard on how to do maintenance. This could be a list of which bolts to tighten and which places to lubricate when and how, what where and when to inspect, and so on. This may also include elements related to cleanliness (5S). Like any standard, someone also needs to occasionally check to make sure the standard is followed, and there should be a process on how to improve the standard. This training and the resulting standard should also include steps to alert maintenance personnel if the worker notices something out of the ordinary. The current state could also be part of the shop floor meeting or shift handover. There could also be documentation on the performed maintenance steps.

When implementing the new autonomous maintenance standard, it is good practice to do this for a well-functioning and clean machine. Hand over the responsibilities to the worker for a machine in perfect working conditions, not a barely functioning piece of junk. Depending on the situation, you may even do modifications to the machine to make autonomous maintenance easier or even possible in the first place. At the same time, don’t expect miracles. If the machine has bigger problems, you still need a properly trained maintenance guy. The same applies to safety critical repairs. You don’t want an amateur twiddling with your gas pipes or the high-voltage power lines. Make a clear distinction on what the worker can and is allowed to do, and what not.

Overall, autonomous maintenance is a very important and valid tool for maintenance. It can be used in almost any shop floor, to the benefit of the entire system. Now, go out, teach your people how to take care of their equipment, and organize your industry!

P.S.: Many thanks to Leandro Barreda and Gil Santos for nudging me to write about maintenance.

Series Overview

- A Brief History of Maintenance

- What Are the Goals of Maintenance?

- An Overview of the Eight Pillars of Total Productive Maintenance

- The Pillars of TPM – Focused Improvement

- The Pillars of TPM – Autonomous Maintenance

- The Pillars of TPM – Planned Maintenance

- The Pillars of TPM – Early Equipment Management

- The Pillars of TPM – Quality, Training, Administration, and Safety

- The Pillars of TPM – The Missing Pillar Reactive Maintenance?

Dear Professor,

Totally agree on “Make a clear distinction on what the worker can and is allowed to do, and what not.” Some times supportive employees tend to hide repetitive small problems because they think is their task to fix it, and it hides the root cause.

Over that… TPM is a great way to work!

very good tool if it is well understood and utilized by all stakeholders

An Excellent article as always Christoph and thank you for all your content and informed discussion. I absolutely agree, autonomous maintenance is an excellent tool with the distinctions clearly marked and understood as Leonadro and Martin wrote. Deviations must be captured and raised to shift leaders. Autonomous maintenance although, as in the main text, adds work can give pride and ownership it certainly goes some way into addressing the Human Factors, the so-called ‘Dirty Dozen’. BTW – I found one page lessons a revelation for communicating what needs to be done.

If used properly it can address the shortage of multi-skilled workers, the so-called eighth waste with practical skills and knowledge of problem solving providing the frequency of extra work and reasons why. In short it can be an excellent for capturing ‘tribal knowledge’.