Turning job shops into flow shops is not easy. This is my second post explaining such transformations as I try to help you in improving your shop floor from an (always) messy job shop into a much more efficient flow shop.

Add Flexibility

Another possibility to consider is the flexibility of your processes. Can you change the process so it can handle more product types? If you have some products that are milled and others that are turned, can you use a machining cell that can do both instead of a separate mill and late?

For automated machines this may be a larger investment, but for manual processes this is often much easier. Can you train the worker at one process to be able to also make the other products? You may have to provide some more tools that are required for this process, but this may be not as expensive.

Just keep an eye out for the changeover time. If the changeover time is large, you may be forced to use larger lot sizes … or do a changeover optimization, better known as SMED.

A common example for such flexibility is automotive assembly lines. A few decades ago, an automotive assembly line was dedicated to one type of car, and you had separate lines for different models. Then Toyota started to use mixed model lines, where different car models are produced on the same line. Currently they have lines where seven or more different models are produced on the same line. This was not an easy process, and it required quite a few specialized tools. For example, the car body is clamped down during welding and assembly. These clamping points are different for different models. Toyota built a triangular base, where every side of the base has the clamping tools for a different model. If another model has to be produced, the tool simply rotates to have the correct clamping points. This can be done on the fly, the changeover time is effectively zero, and Toyota can make multiple models on the same production line. Now this is very common with other car makers as well.

Add Capacity

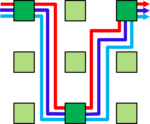

Another possibility is to add capacity. This is also visualized (albeit simplified) in the image below. Through the strategic adding of three processes, it was possible to transform the job shop into four parallel flow lines.

True, these additional processes will probably be not 100% utilized, but this is often a manageable problem. As I explained in my previous post about skipping and adding processes, for automated processes we don’t care, and for manual processes we can use a bucket brigade, rabbit chase, chaku chaku line, mixed model sequencing, or similar methods to distribute the workload.

On the downside, however, you will need some investment, but this is offset with the benefit of a much more efficient flow line instead of a chaotic job shop. The benefits of a flow line are not to be underestimated. Another problem is often the floor space. Many factories are cramped, and there is little available space. However, as a flow line usually has much less inventory than a comparable job shop, you will probably save space that is occupied with material. With a little bit of luck, this is enough for the additional processes, or even a bit more.

Design Change

Another possibility is to change the design of your products so that they are more similar and hence more suitable for flow lines. I know that changing product design is hard, but I never claimed that turning a job shop into a flow shop is easy. However, it is often worthwhile.

Such a design change probably also has additional benefits, as for example a reduced variety of components or easier automation through similar design. The keywords here are Design for Manufacturing (DFM) or Design for Assembly (DFA) or the combination Design for Manufacturing and Assembly (DFMA). This is also commonly done in industry through modular strategies or platform strategies. Different models from the same car maker often contain a lot of identical parts. Often, the clamping points are identical even though the models itself are different. At Volkswagen this would be, for example, the Modularer Querbaukasten, or MQK for short, although it is not sure if this met the expectation of Volkswagen…

Iterate the Above

Now we have a couple of ways that can help you to turn a job shop into a flow line segment, a flow line, or a complete flow shop. These are:

- Identify Materials with Similar Process Sequences

- Separate Line for Flow Parts

- Skip a Process, Add a Process

- Add Flexibility

- Add Capacity

- Design Change

These are not a particular sequence, but rather a bullet list that you should iterate through a few times. You could. for example. identify similar materials and create a flow segment, only to later find out that through machine flexibility or a design change you can extend the flow segment into a flow line. Hence think things through a few times until you have collected enough ideas for the next step.

These are not a particular sequence, but rather a bullet list that you should iterate through a few times. You could. for example. identify similar materials and create a flow segment, only to later find out that through machine flexibility or a design change you can extend the flow segment into a flow line. Hence think things through a few times until you have collected enough ideas for the next step.

Also, it is not always possible or even suggested to convert a job shop into a flow shop in one major transformation. More likely, you will have to do this in smaller steps. Create a flow segment here, another line there, and bit by bit move towards a flow shop.

Implementation Plan

Once you have identified your flow segments or lines, it is time to implement.

Rearrange Processes in Sequence

Rearrange the processes in the sequence of the flow line. A flow line benefits mostly from this rearrangement. If the process sequence is a flow, but the material still zig-zags across the shop floor, you will loose a lot of the benefit of flow lines. It is no longer easy to see where the material is, the material handling will be much more work, and it is tough to plan and organize.

Hence try to arrange your processes in sequence as much as you can. If a particular process is difficult to move (very large and heavy, built in foundations, or other constraints that make a move unpractical), can you arrange the other processes around it? The more the processes are in line, the better.

Organize Material Flow

Another benefit of the flow line is the easier way to organize the material flow. Can you create a rolling lane, hanging spacecraft transport, conveyor belt, or similar mechanized or automated transport? Or, even if you still transport it manually, can you at least create a good standard for the material transport? If in any way possible, make it a FIFO sequence!

At this time you should also consider how much buffer inventory you want. This is best estimated, as a calculation would be quite messy. It may turn out that you can move the processes much closer to each other and save a lot of valuable floor space.

Improve Processes and Create Standards

Finally, since you have arranged the processes in sequence and managed the material flow, can you also standardize and improve the processes themselves? Now since there should be only very similar parts arriving at the processes, you may be able to tweak these processes to get more performance out of them.

As for the work assignment, can you do a fully manned balanced line? Or will you do a bucket brigade, rabbit chase, or a chaku chaku line? There are lots of possibilities, similar to any new line layout. Covering them all would be beyond the scope of this blog post, but let your imagination run wild.

It may look difficult or even impossible to convert your particular job shop into a flow shop. However, a lot of companies have turned job shops that “looked impossible” into flow shops.

The image here shows an aircraft assembly line. Trumpf uses assembly lines for large machine tools with a takt of eight hours. There were probably also a lot of people in both cases that said that it will never work, but in the end it did. It was not a smooth and easy way, and a myriad of problems had to be solved to make it possible, but at the end it worked!

So, do you think it is possible for your own job shop to move in the right direction and toward a flow shop? Even for only some segments? Okay? Now go out, tackle the beast of a job shop, turn it into a (partial) flow shop, and organize your industry!

P.S.: This blog post was inspired by a part in a video presentation by Nampachi Hayashi, which I found through an article by Dirk Fischer. Thanks to all 🙂

Hi Christoph,

first of all thank you for your very interesting articles on the subject!

One question: do you think, like me, that scheduling becomes easier for a line than for a job-shop (product-layout)? For example, if you use a Conwip-method, you need to first identify a line to apply Conwip, do you agree with me? A Conwip is more difficult for a process-layout…

Thanks in advance,

Sandro Rizzoli

Bologna (Italy)

Great commentary!

Onc again makes you think of options…

Hi Sandro, CONWIP in my opinion also works for job shops. However, any kind of scheduling and planning becomes easier in flow shops.

Hi Christoph, I agree with you that Conwip could work also in a jobshop, but a problem could be to calculate the Conwip-level with a floating bottleneck…

Funny thing is I run a Job shop, it’s very neat and organized, but it is in a Toyota plant and called a kaizen shop.

Well done. After leaving Toyota and joining Allied Signal Automotive there were many challenges for job shop environments especially when we were asked to help the Aerospace Sector. The most urgent at the time was the APU refurbish/repair facility in Germany. CEO Bossidy called and said the fix had to be accomplished in two to three weeks. You nailed the keys to success especially setting up flow, organizing all processes, standard parts storage with pull and implementing a planning process, We used past history, number of aircraft in customers fleets, age and locations. The old process was to order repair parts after receipt of the APU and inspection. By using past history, forecasts and lead times the parts inventory was developed and the site manager accepted the added inventory to increase throughput (and save his job). In 14 long days the site was reorganized and the parts ordered on day one were arriving. The output increased 50%. It took six weeks to double to meet demand. The word from the CEO is that he should have set ten days for the target.. One principle reinforced was to look at lowest total cost and not to sub optimize costs like he was with minimum inventory.

Many thanks for the inspiring success story, Ronald 🙂