Job shops have a strong tendency toward chaos. Even well managed plants struggle to maintain order in a job shop. This is due to the inherent nature of a job shop, and there are no good solutions to manage job shops. The only good way to improve a job shop is to turn it into a flow shop. I will talk more about such changes later in this short series, but first let me explain why job shops are always a mess.

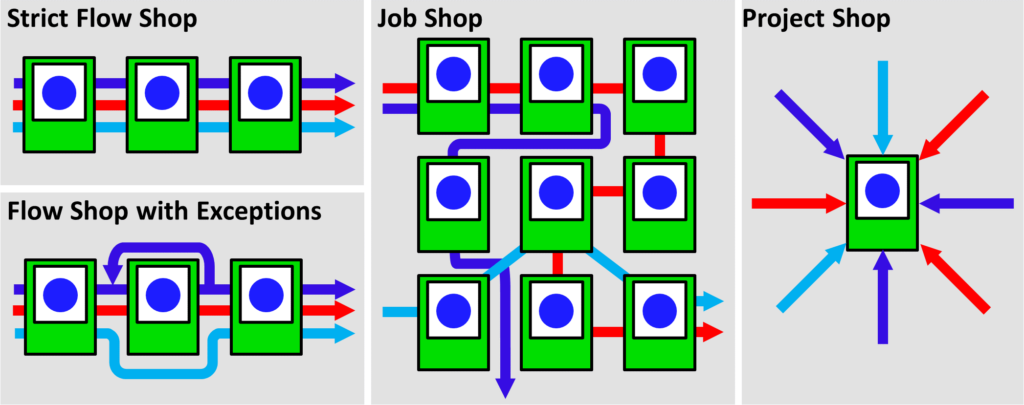

Flow Shop, Project Shop, Job Shop

There are three main groups of material flows in manufacturing. First, there is the flow shop, where the main material flow is the same for all products (i.e., all products have the same process sequence). Second, there is the job shop, where the material flow is different for all products. Finally, there is what I call the project shop, where all material flows to one process only. This is not that common, but can be found, for example, in shipbuilding, where everything comes to the ship in the dry dock. Please also note that these types of material flow have a large overlap. There are plenty of flow shops where some material has exceptions, and plenty of job shops where there are small stretches of flow-shop-like behavior.

I have written about flow shops, job shops, and project shops before, but flow shops are usually much, MUCH easier to plan and manage. Let me show you why job shops are such a source of chaos.

Irregular Material Flows Cause Inventory Imbalances

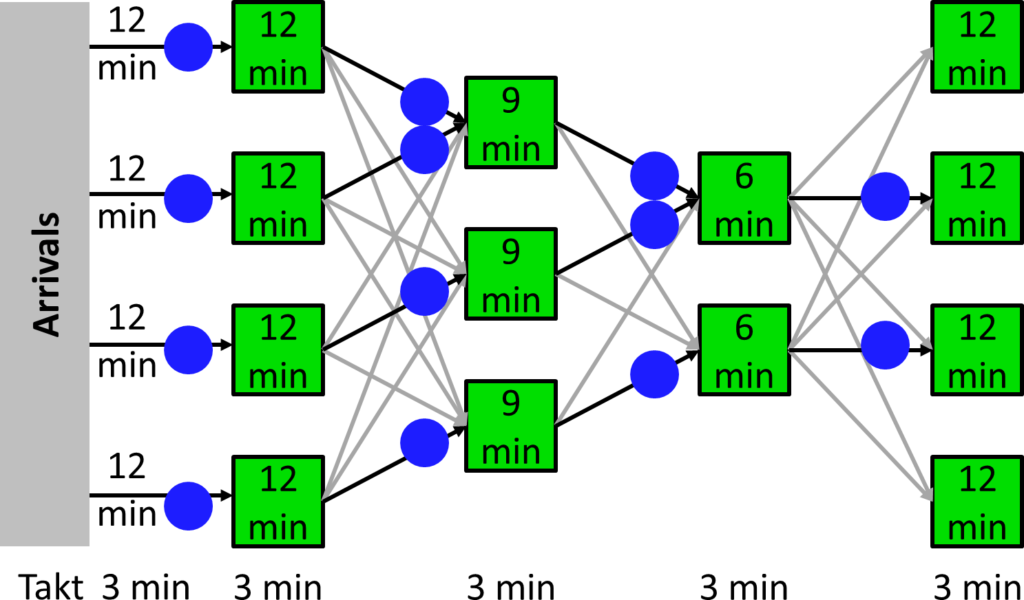

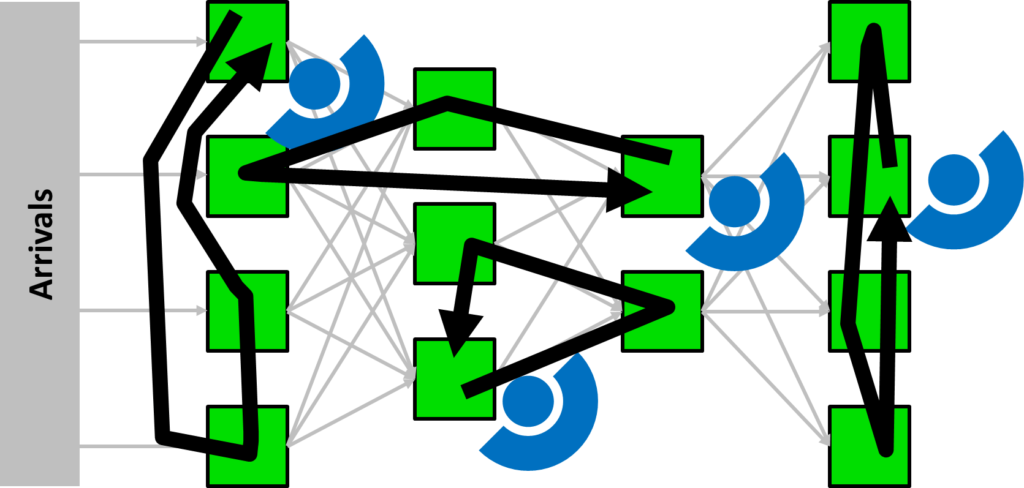

One of the main causes of problems typical to a job shop are irregular arrivals. Below is a hybrid between a flow shop and a job shop, to illustrate the point. Material flows from left to right, but may be processed by different machines at different steps. I use this hybrid, rather than a full job shop, to make the points easier to understand, but trust me, it is worse in a full job shop.

Furthermore, to simplify the argument, let’s also assume that the processes are nicely balanced and every part can be processed at every machine, and also let’s assume not to have any randomness. (Yeah, absurd, I know. But it is the privilege of professors to make unrealistic assumptions so that it works in theory. 😉 ) Anyway, on the first column a part arrives at every process every 12 minutes, hence our arrival takt is 3 minutes. The first column of processes can process a part every 12 minutes, which gives these four processes together also a takt of 3 minutes. The second column of processes needs 9 minutes per part and process, which gives also a takt of 3 minutes. The third column needs only 6 minutes per part and process, again for a takt of 3 minutes. And the last column needs again 12 minutes per part and process, for a takt of … 3 minutes.

Hence overall, the processes in this example are nicely balanced, with every stage of these four process columns having the same capacity. If you would be producing water, it would flow though the system at the same speed without being slowed down.

Unfortunately, you are not producing continuous goods like water, but discrete goods like parts. Hence, you will sometimes have two parts arriving at the same time at the same process, and sometimes none. Even with the best distribution rule, you will have more material at some spots and less at others. The material distribution is uneven.

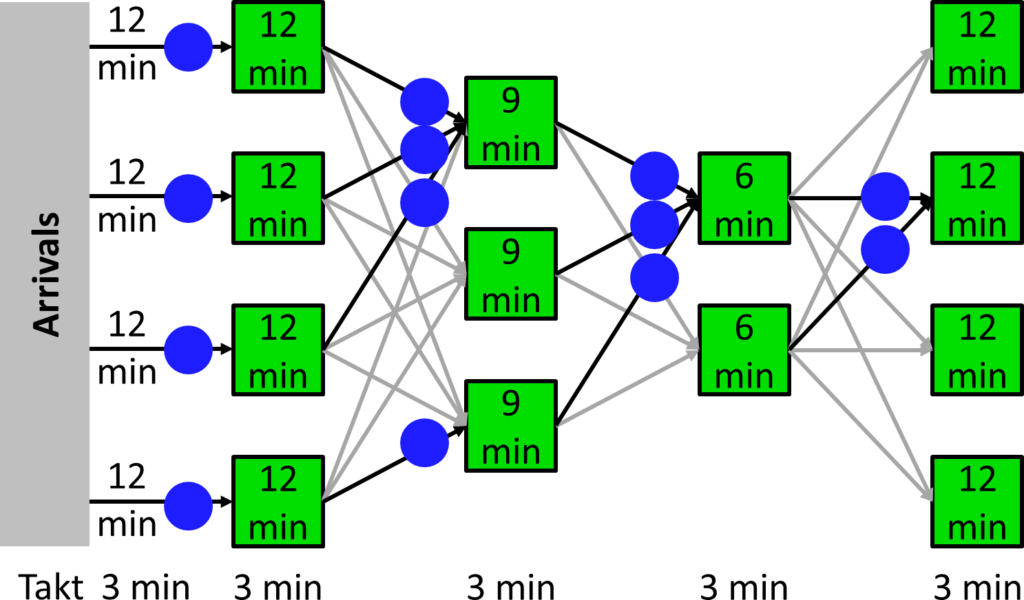

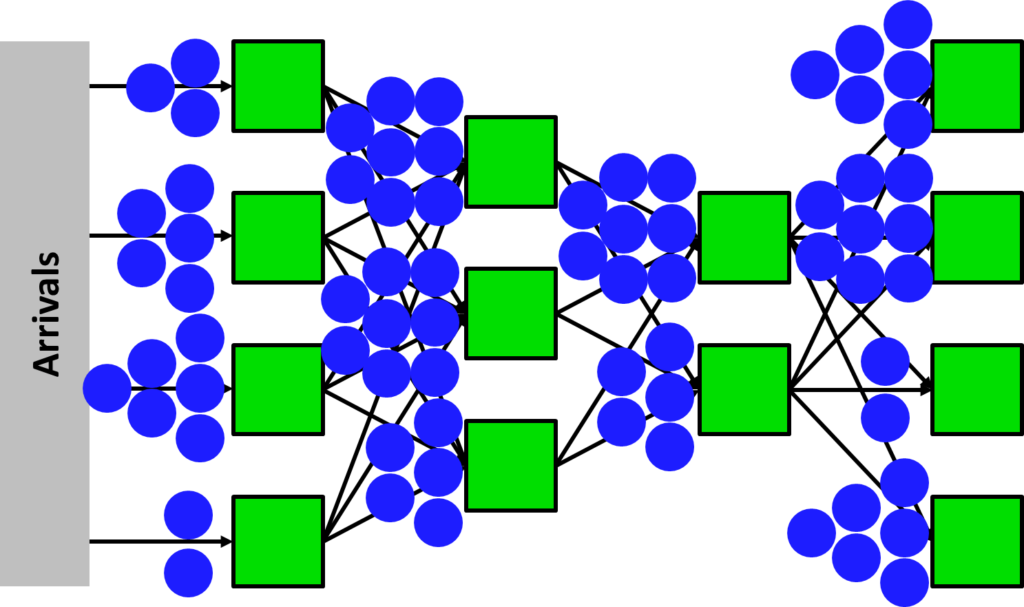

The above example also assumes every part can be processes by every machine. If we would have the restriction that some parts can be processed only by some machines, the “clumping” of material will quickly become even more pronounced as shown below.

And, remember, this is a perfectly balanced system without any randomness (i.e., my theoretical example). If you add random events (breakdowns, short delays, etc.) and make the system imbalanced (you have a bottleneck that may also depend on the part mix produced), it will become even worse.

The point here is that depending on the arriving product mix, the arrival of material at a process is fluctuating widely. One process may have multiple parts arriving almost simultaneously, whereas other processes may have none. If more parts arrive than what the process can handle, the material starts to pile up. If less arrive than what the process can handle, the pile will shrink and eventually disappear, causing the process to idle.

Inventory Imbalances Cause Large Safety Buffers

Having clumps of material in your value stream is not good. But for the shop floor, often even worse are idling workers. A worker that is unable to work due to a lack of material is waste. To be more specific, it is the waste of waiting as part of the seven types of waste (muda).

To prevent or at least reduce such waiting times, the inventory in front of the processes is increased. If there is more inventory, the likelihood of having to wait is reduced … but at the cost of increased inventory.

Inventory Imbalances Cause Changes in Staffing

Imbalances in the workload can be buffered somewhat by inventory. Larger imbalances, however, eventually require some processes to work more than others in the long term. This is usually done by reassigning workers. If a process is running out of parts, the workers are reassigned to an process that has way too many parts. In a flow shop, workers often work for longer periods at the same spot, changing the location only at predetermined times. In job shops, such changes are much harder to predict. It is usually impossible to have a preventive planning of the staffing, but only a reactive action. If the process runs out of parts, you check where the workers are most urgently needed (and qualified to work at), and reassign the workers there.

In my next post I will continue to lament about the woes in a job shop … which unfortunately does not help you much except that I know your pain in managing a job shop. In the post after that, however, I will look into how to transfer a job shop into a flow shop. Now, go out, wrangle with the multi-headed hydra that looks like a job shop, and organize your industry!

P.S.: This blog post was inspired by a part in a video presentation by Nampachi Hayashi, which I found through an article by Dirk Fischer. Thanks to all. 🙂

Hi Cristoph – job shop flow is a challenge. Parts are different, requiring separate equipment, components, etc. How are you depicting manufacturing cells in a job shop?

Hi Charles, manufacturing cells have different definitions, but here I believe they are small “flow line segments within a larger job shop.

Hi Cristoph,

I appreciate your insights into job shop production. For years, I have been helping with management of complex job shop production which you described as chaotic. I use the word “complex” in place of chaotic which I use to describe a high level of uncontrollable natural variation and uncertainty within the system.

By releasing material to shop floor for every job at an “optimal” time, we can manage job shop production very efficiently. It will create minimal inventories at work centers while achieving maximum throughput and on-time delivery.

But, finding optimal material release time requires advanced calculations which are mostly available in powerful job shop scheduling software. Almost everyday, I discuss about complex job shop issues on LinkedIn. My articles can be seen at

https://www.linkedin.com/in/prasadvelaga/detail/recent-activity/posts/

Hi Prasad, “complex” to me is here a synonym for “chaotic”. There are ways to handle job shops, but they do not solve the underlying problem of the chaos, but merely address the symptoms. Besides, I am always dubious if someone claims something is “optimal” anywhere in manufacturing, job shop or not. If it is optimal, then there would be no room for improvement, which goes against my philosophy in lean.

Always nice post. BTW, as you know, there is an another model so-called “Hybrid” model. For example, a Job Shops manufacturer, by facing with more difficult request (shorter lead-time, lower costs, etc.) by the client, try “Flow” (at up-stream processes) + Job Shops (at down-stream processes) or Job Shops (at up-stream processes) + “Cell” (at down-stream processes), etc. Then, if possible, I hope to describe such model in the near future.

Hi Osamu, good comment as always. Actually, in the quest to change a job shop into a flow shop a short term goal is always t o make sections of the job shop into a flow shop, exactly as you mentioned. I will have more on this in subsequent posts which I have already prepared.

I found an interesting approach to Job Shop and Lean Manufacturing at this site

http://www.strategosinc.com/job_shop_lean_manufacturing.htm

By studying current Job Shops in Japan, I would like to introduce more (adding to Hybrid model) for “How to settle some problems on Job Shops?”

1. They (almost small) are trying to implement Multi-Process Handling workers, to work like “flow” (not need to transfer the parts to another pocess).

2. They are studying GT (Group Technology) for the operation (same or similar) and then realizing “flow”.

3. They implement cheap machines to make “flow”, instead of expensive machine.

This means the machine operator works within “flow”.

The tasks (shorter lead-time, lower costs, be flexible) they face needs various Job

Shops operation.

Hi Osamu, thanks for the follow up on your previous comment. Agree with all of them, although I am not sure what exactly you mean by group technology. Is this designing parts around a similar backbone like platform technology? I will talk about this in my upcoming posts.

Hey Christoph,

for me a another example for a project shop or job shop, is the special machine manufacturer. As a turn-key-solution supplier often the automatic assembly lines with gantrys, robots for the production of Rotor, Stator in E-Motors or crankshaft production lines are so big, that the whole material flows to one defined place in the shopfloor. There the whole line is mounted and programmend. For me the crazy thing is allways, that we produce automatic lines and machines which are optimized for SMED, flow shop and ergonomic, but for ourselves we can’t do it. But more because we don’t want it , because the leadership has no lean understanding.

Have you researched the POLCA card system?

Two sets of cards circulate, which helps prevent a job being released for an operation that is currently busy.

It has been around for years; here is a recent book:

The Practitioner’s Guide to POLCA: The Production Control System for High-Mix, Low-Volume and Custom Products by Rajan Suri

Hi Sean, yes I do. I have a series of articles on POLCA, and a chapter of my Book “All About Pull Production” is on POLCA. The inventor Rajan Suri helped me a lot in writing these.