In this second post of the series on our van full of nerds touring southern Germany to study Industry 4.0, we will look at ABB Stotz-Kontakt in Heidelberg. Quite an impressive plant! Let me show you:

In this second post of the series on our van full of nerds touring southern Germany to study Industry 4.0, we will look at ABB Stotz-Kontakt in Heidelberg. Quite an impressive plant! Let me show you:

ABB Stotz-Kontakt Plant in Heidelberg

The Plant

Out of all seven plants we visited, I liked the Industry 4.0 aspects of the ABB Stotz-Kontakt plant in Heidelberg the most. While some plants go overboard with Industry 4.0, at ABB Stotz it seemed to be a good and productive discussion about when and where to use computer. For example, the plant manager prefers digital dashboards, whereas the production manager prefers paper-based dashboards. Rather than just overruling the production manager, there seems to be a constructive discussion. While I prefer paper, my hope is not that “one side wins,” but rather both sides come to an agreement.

Out of all seven plants we visited, I liked the Industry 4.0 aspects of the ABB Stotz-Kontakt plant in Heidelberg the most. While some plants go overboard with Industry 4.0, at ABB Stotz it seemed to be a good and productive discussion about when and where to use computer. For example, the plant manager prefers digital dashboards, whereas the production manager prefers paper-based dashboards. Rather than just overruling the production manager, there seems to be a constructive discussion. While I prefer paper, my hope is not that “one side wins,” but rather both sides come to an agreement.

The ABB Stotz-Kontakt plant dates back to the Stotz und Cie company from 1891. While they are part of ABB since 1988, the people still feel that they are Stotz first and ABB second, and keep their distinct identity.

The ABB Stotz-Kontakt plant dates back to the Stotz und Cie company from 1891. While they are part of ABB since 1988, the people still feel that they are Stotz first and ABB second, and keep their distinct identity.

It is a plant producing circuit breakers near Heidelberg. They have around 1,200 employees. The first good sign of correct priorities was their safety instructions. While most plants we visited glossed over them, this company spent three to five minutes actually covering the important parts (including “hands on railing” on stairs, and “no mobile phone use while walking”). Also, all employees have a minimum of a Lean Six Sigma white belt. In addition, most of the employees have yellow, green, and some a black belt. While I am not a fan of Six Sigma, it is basically a quick fundamental lean training. They have two main assembly lines. The lines run twenty-four hours a day six days per week.

Lean Aspects

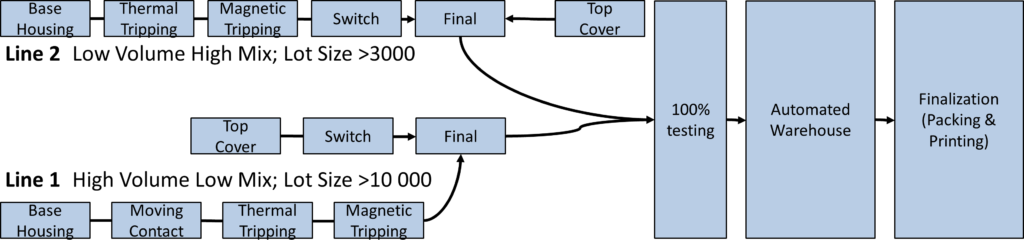

Line 1 is a fully automated one for high-volume, low-mix production. About 160 variants are produced on this line. Production is economic for lot sizes above 10,000 circuit breakers. Line 2 is a mix of automated and manual line for low-volume, high-mix production. This line handles 450 different variants and is economic for lot size 3,000 and up. The total changeover time of line 2 is about 90 minutes, but due to a running changeover, the lost production time is only 4 minutes. Some labor-intensive parts are received from a second plant in Bulgaria (low labor cost). Line 2 has a cycle time of 1.2 seconds, while line 1 has stations doubled resulting in a cycle time of 0.6 seconds.

They also use a 3D computer tomography machine with a resolution of 0.1μm resolution to analyze circuit breakers without opening them.

Compared to some other automated lines in other plant, the workload of the employees was appropriate (another company we visited had employees wasting a lot of time with idling, waiting, and other wasteful things). The material flow was very well visualized. They used stack lights extensively, but did not go overboard with too many stacks. Most machines had a stack light with only one color, some two, and very few three.

Compared to some other automated lines in other plant, the workload of the employees was appropriate (another company we visited had employees wasting a lot of time with idling, waiting, and other wasteful things). The material flow was very well visualized. They used stack lights extensively, but did not go overboard with too many stacks. Most machines had a stack light with only one color, some two, and very few three.

For additional visualization they also had a triangular LED running text that gave more details on the error through an error code and an error text. This way it was already visible from far away what the problem at the machine was.

For additional visualization they also had a triangular LED running text that gave more details on the error through an error code and an error text. This way it was already visible from far away what the problem at the machine was.

They also used some ABB YuMi collaborative robots (Cobots) to pack breakers into blister packs for retail. These robots were of an unusual design, having two arms per robot. Even though these are designed for collaboration and stopped when touched, they were partially shielded at head height to prevent eye injuries, where even a slight touch can hurt quite a bit. Nevertheless, these Cobots managed to keep work in Germany that was already scheduled for Bulgaria.

Industry 4.0 Aspects

Their approach to industry 4.0 was very structured. Every project that they do needs a business case. They had quite a few projects, but structured them into Focus Projects; In Progress; Quick Wins, and IT Standards. These projects are also grouped into four areas: Energy Management; Product Improvement; Smart Devices; and Quality Improvement. Below is a selection of these projects.

- Focus Projects

- Smart Wall for Shop Floor Management: For daily shop floor production meetings

- Workforce Management Systems: Allocation of work, skill matrix

- 3D printing of Molds: Faster prototyping, cost reduction

- In Progress

- Energy Monitoring (Power): Monitoring, cost calculation

- Energy Monitoring (Air Pressure): Monitoring, cost calculation

- Standard common data layer and HMI for line/plant production data: Common data structure for easy analytics

- Augmented Reality for Remote Support: Internal maintenance, external support, training, etc.

- Quick Wins

- Swift Insight IoT Production Monitoring System: Analysis of production data

- Wearable Devices: Receive downtime information, support

- IT Standards

- Standard for IoT devices: Standard for IoT at ABB

- Network Infrastructure (WIFI): Stable WIFI in all locations

- Cyber Security: Reduce risk, reduce exposure

All of these had a clear structure and a business case somewhat similar to an A3, and also a rough timeline. The project was described; the scope defined; current situation was presented; the expected outcome was given; a cost/benefit decision matrix with the main cost drivers was made; and an overview of the benefits was provided. Since the business case for such projects can often not be calculated numerically, it was often only a tendency (e.g., transparency up; cost down…).

To show just a few examples: They are experimenting with a digital assistant for manual assembly of the most low-volume products. The product is by a German company Ulixes, and provides a projection on the work surface to assist with assembly. Their demonstration video is below.

However, the implementation is far from certain. The risk of this system is that the worker feels belittled and micromanaged, and his skills not valued. They are discussing this, working together with the employees to see if it is really a help or just an expensive nuisance.

They are also experimenting with Microsoft HoloLens for remote support and maintenance, as for example with their plant in Bulgaria. HoloLens are augmented reality glasses where you can add visualization of digital data on top of the real world environment. As Ulixes, this is in testing at ABB to see if it is truly useful or not (yet).

They are also experimenting with Microsoft HoloLens for remote support and maintenance, as for example with their plant in Bulgaria. HoloLens are augmented reality glasses where you can add visualization of digital data on top of the real world environment. As Ulixes, this is in testing at ABB to see if it is truly useful or not (yet).

Again, the strong point we saw at ABB was this hard work to find out if a technology is really useful before it is rolled out on the shop floor. If you skip that, then you will waste time and energy. Overall, we all liked the plant very much, and many of us considered this to be the best plant in the tour.

In my next post we will visit Trumpf. I have posted about Trumpf before, and am quite impressed with their approach to business. My previous posts were about the main plant in Ditzingen, and this time we visited a much smaller plant in Gerlingen making stamping tools. Until then, stay tuned, go out, and organize your industry!

P.S.: Thank you very much to everybody who hosted us and showed us their plants and products!

Post Series Overview

- Industry 4.0 Tour in Germany – A Van Full of Nerds – Overview and Audi

- Industry 4.0 Tour in Germany – A Van Full of Nerds – ABB Stotz-Kontakt

- Industry 4.0 Tour in Germany – A Van Full of Nerds – Trumpf Gerlingen

- Industry 4.0 Tour in Germany – A Van Full of Nerds – Bosch Reutlingen Wafer Fab

- Industry 4.0 Tour in Germany – A Van Full of Nerds – Kärcher and Siemens

- Industry 4.0 Tour in Germany – A Van Full of Nerds – Presentations and Tryouts

Excellent report!

Gracias por compartir tu tour. Una excelente experiencia!!!.

Great report, thanks!