Your products may have different work content on your production line, which may make your line less efficient. One possible solution is Mixed Model Sequencing, a way to adjust the sequencing of your products to make the average work content stable. In previous posts I looked at the basics, at how to avoid the problem in the first place and how to play with capacity. However, especially for large complex lines (i.e., automotive), sequencing is often a suitable approach to manage different work contents.

Your products may have different work content on your production line, which may make your line less efficient. One possible solution is Mixed Model Sequencing, a way to adjust the sequencing of your products to make the average work content stable. In previous posts I looked at the basics, at how to avoid the problem in the first place and how to play with capacity. However, especially for large complex lines (i.e., automotive), sequencing is often a suitable approach to manage different work contents.

Principle of Mixed Model Sequencing

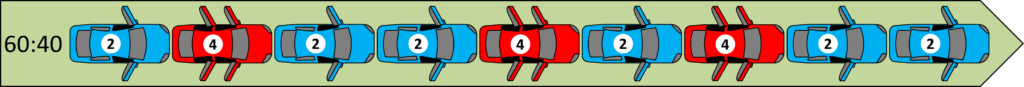

Some of your products have a higher workload at a workstation (e.g., a four-door car at the door assembly). Hence, the other products have a lower workload (e.g., a two-door car at the door assembly). The basic idea is to alternate these products, and set up the critical station so that they can handle the average workload. For example, you alternate two-door and four-door cars, and the door assembly is designed to assemble three doors on average per cycle. I tried to illustrate this with the animation below, where two people on average assemble three doors each per cycle.

In the following I will explain the fundamental approach to resolve a single unbalanced workstation. However, in reality you will have multiple workstations whose workload is affected by the product type. This makes everything more complex – but more about this later.

A Bit About Takt Times

If you have a station with a mixed workload and hence a mixed cycle time, you try to set the average cycle time equal to the overall cycle time of the line. Or, to be more precise, you set the average takt time of the mixed workload station to the average takt time of the line. For more on the difference between cycle and takt time, see my post On the Different Ways to Measure Production Speed.

If you have a station with a mixed workload and hence a mixed cycle time, you try to set the average cycle time equal to the overall cycle time of the line. Or, to be more precise, you set the average takt time of the mixed workload station to the average takt time of the line. For more on the difference between cycle and takt time, see my post On the Different Ways to Measure Production Speed.

Two-Door and Four-Door Example

For example, your typical automotive assembly line completes a car every 60 seconds. Let’s assume mounting four doors takes twice as long than two doors (even though this is technically not quite true; e.g., front doors often have more electronics).

The next information you need is the ratio of two doors to four doors (or, generally speaking, how many products of which type do you have). Here I will calculate for you the cycle times in dependence of the percentages of two-door and four-door vehicles. Assume the following variables:

- TT: Takt time of the entire line (the line takt)

- TT2: Takt time for the mounting of two doors

- TT4: Takt time for the mounting of four doors

- P2: Percentage of the cars that are two doors

- P4: Percentage of the cars that are four doors

In this case the following equation must hold true:

\[ { TT = TT_2 \cdot P_2 + TT_4 \cdot P_4}\]where

\[ { P_2 + P_4 = 100 \%}\]or

\[ { P_4 = 100 \% – P_2}\]In our case we assumed that four doors take twice as long as two doors, hence also:

\[ { TT_4 = TT_2 \cdot 2}\]Using this additional information, we can simplify the first equation as follows:

\[ { TT = TT_2 \cdot P_2 + TT_2 \cdot 2 \cdot (100 \% – P_2)}\] \[{ TT = TT_2 (P_2+ 200 \% – 2 \cdot P_2)}\] \[{ TT = TT_2 ( 200 \% – P_2)}\] \[ { TT_2 = \frac{TT}{200 \% – P_2}}\]Depending on the share of two doors and four doors, you need to get the takt time to a certain value so the average takt time is consistent with the line takt. I have plotted this relation for you below (assuming four doors take twice as long as two doors, with a line takt of 60 seconds).

If you make only four-door vehicles (i.e., 0% two-door vehicles), then you need to get the takt time of four-door vehicles to 60 seconds. Similarly, if you make only two-door vehicles, you also need to get the takt time of two door vehicles to 60 seconds. If you make 50% of each, then you need a takt time of 40 seconds for the two doors and 80 seconds for the four doors for an average takt of 60 seconds.

General Equations

The above example was for only two types of products (two and four doors), and we knew exactly the relation of the takt times between them (four doors take twice as long).

The above example was for only two types of products (two and four doors), and we knew exactly the relation of the takt times between them (four doors take twice as long).

In reality, you may have many more different products. The relation of their takt times may also be not well defined. The takt time may even change between zero and a larger value (e.g., if you install a sunroof or if you do not). Generally speaking, if you have k different products with

- TT: Takt time of the entire line (the line takt)

- TTn: Takt time for product n

- Pn: Percentage of the produced items that are of type n

Then the general formulas would be as follows:

\[ { TT = \sum_{n=1}^{k} TT_n \cdot P_n }\] \[ { \sum_{n=1}^{k} P_n = 100 \%}\]The sum of the shares of the takt time has to be the line takt, and the sum of all shares has to be 100% (or 1 if you use mathematical notation). The challenge is to figure out this equation without knowing how much longer part type 25 takes in comparison to part type 33, and all in between. You probably also won’t get hard numbers for the percentages, as they are only future predictions, and, hey, customers change their minds all the time, especially in the future.

For a mathematician this would be a disaster, having an equation where you don’t know for sure what the values are. In lean we have this all the time, and hence you are probably familiar with the concept of guessing. If you don’t have a number, just ask an expert for his opinion, or take the best guess you can get (it may even be your own guess).

Also keep in mind that you can change the takt times by getting better tools. Use jigs, rigs, and other gizmos to reduce a takt time that causes you problems. More on this later. You also don’t need to be perfect with your math. The progress of timing a production line includes a lot of uncertainties, and just getting close to the targeted value is good enough. If the random chances turn against you and it takes too long, then you just have to put in an improvement effort to make it faster again.

So, this is the fourth post on product-dependent workload, and the first on sequencing. The sequencing part is actually a bit tricky, hence there will be a few more posts on this type of sequencing. Until then stay tuned, and go out, and organize your industry!

P.S. Many thanks to Mark Warren for his input.

Series Overview

- Mixed Model Sequencing – Introduction

- Mixed Model Sequencing – Just Make the Problem Go Away

- Mixed Model Sequencing – Adjust Capacity

- Mixed Model Sequencing – Basic Example Introduction

- Mixed Model Sequencing – Basic Example Workload and Buffering

- Mixed Model Sequencing – Basic Example Sequencing

- Mixed Model Sequencing – Complex Example Introduction

- Mixed Model Sequencing – Complex Example Data Basis

- Mixed Model Sequencing – Complex Example Sequencing 1

- Mixed Model Sequencing – Complex Example Sequencing 2

- Mixed Model Sequencing – Complex Example Verification

- Mixed Model Sequencing – Summary

Here is also the Sequencing Example Excel File for posts 7 to 11 with the complex example. Please note that this is not a tool, but merely some of my calculations for your information.

Hello Christoph,

Thank you for doing this series on sequencing. It’s a topic of great interest to me and our consulting work, and one that has not well understood in the lean world. I am looking forward to following the series.

There are different lean schools of thought regarding Takt Time, and I wanted to comment on the terminology used in this chapter. When we teach this subject we are very clear about the difference between takt and work content. Takt is calculated by dividing available work minutes by forecast demand or volume for a process, and the result is the desired “beat” of the process. This is calculated process by process, and a value stream could have many different takt times depending on options, rework, scrap, quantity needed. But there is nothing in the takt time formula that has anything to do with work content.

Individual models do not have takt (the way it is normally calculated) but they do have work content or “cycle time”. It seems that you are using the term takt to refer to work content, which could lead to some confusion. I agree with the logic presented, but my concern is about the terminology. Thoughts?

Hi Richard, As you said, takt is a time period divided by a quantity. I not only use this for the demand (customer takt) but also for the actual output (line takt) or desired output (target line takt … which should be close or identical to customer takt). For a flow line without branching, every process should have the same takt. If the first process takes 1 min/part, the second needs to have the same, otherwise one of them has to wait on the other one and the faster takt time gets slowed down to the slower one. Hence all processes have the same target process takt. Based on the target process takt you can get the target cycle time (essentially a bit faster to account for OEE losses). A station *in average* needs to get a part out every takt. If some parts have a higher workload, and some a lower, you have to make sure that they in average can fit into the takt (and some OEE losses). Does this help?

On a side note, you can very well have a product specific takt. You need this to calculate kanban cards. I.e. if you need 60/hour of A and 20/hour of B, you have a takt of 1 min for A and 3 min for B. Based on this you calculate kanban. Combined A and B gives 80/hour and a takt of 1.33 min, which you need to set up the process/line capacity.

Good Discussion!

Thanks for your feedback, and I am going through your series of articles on sequencing today. I am adding comments as I have them, so you may see more than one!

Regarding your side note on kanban cards: in a mixed model line you may need 60/hour of A today, and 40/hour tomorrow and 80/hour the day after, right? In other words, usage can be variable depending on the daily mix of products. So what I’ve seen at Toyota Material Handling is to calculate the kanban quantities based on forecast usage (from their MRP system), and to overcome the normal variability in usage by having very frequent delivery cycles (every 37 minutes in their case). Works like a charm, although compared to most companies they do a lot of handling. And they use their SAP system to monitor usage trends, and make tweaks to the kanban system automatically and frequently.

At Toyota, they would probably make 60 every day, balancing the demand. For short term variations a buffer is often the easiest way to decouple fluctuations. The number of Kanban would need to be adjusted every now and then, but a daily adjustment is too much in my opinion.