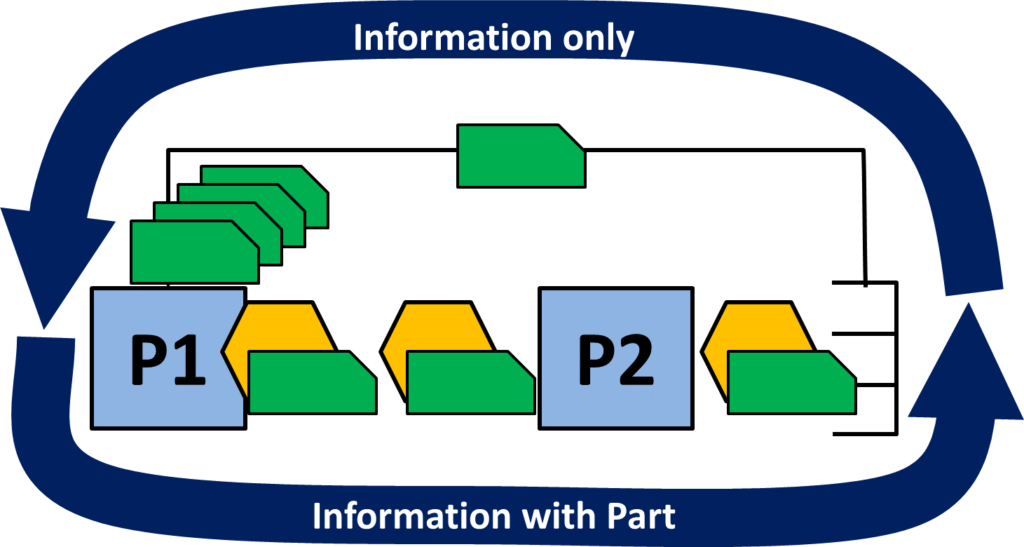

Kanban and similar pull systems like CONWIP or POLCA are basic parts of lean production. They limit the maximum number of parts by attaching a sort of token (i.e., the kanban card) to the part, and return to the beginning when the part leaves the system.

Kanban and similar pull systems like CONWIP or POLCA are basic parts of lean production. They limit the maximum number of parts by attaching a sort of token (i.e., the kanban card) to the part, and return to the beginning when the part leaves the system.

These kanban can be physical cards or digital representations. In this post I look into when you should use a physical kanban and when you should use a digital kanban.

Introduction

The kanban card or CONWIP card goes around the kanban or CONWIP loop repeatedly. Information on a (digital or physical) fresh card arriving signals the start of production. The information then travels with the part through the production process and the corresponding inventories. When the part leaves the loop, the information is returned to the beginning and the process starts anew.

The Speed of the Card

For the outward leg (downstream), the information is attached to the part and moves with the part. Hence, on the downstream path the information cannot be faster than the part. Regardless if it is physical information or digital information, the speed is the same as the corresponding part. Therefore, we cannot influence the speed through our choice of data or physical information.

On the return leg, however, the information is on its own. Therefore, on the way back the (physical or digital) information should go as quickly as possible. The faster the movement of the information, the shorter the replenishment time and the faster the turnaround time. Once the information is back in the production queue, the information has to wait and the speed is no longer relevant.

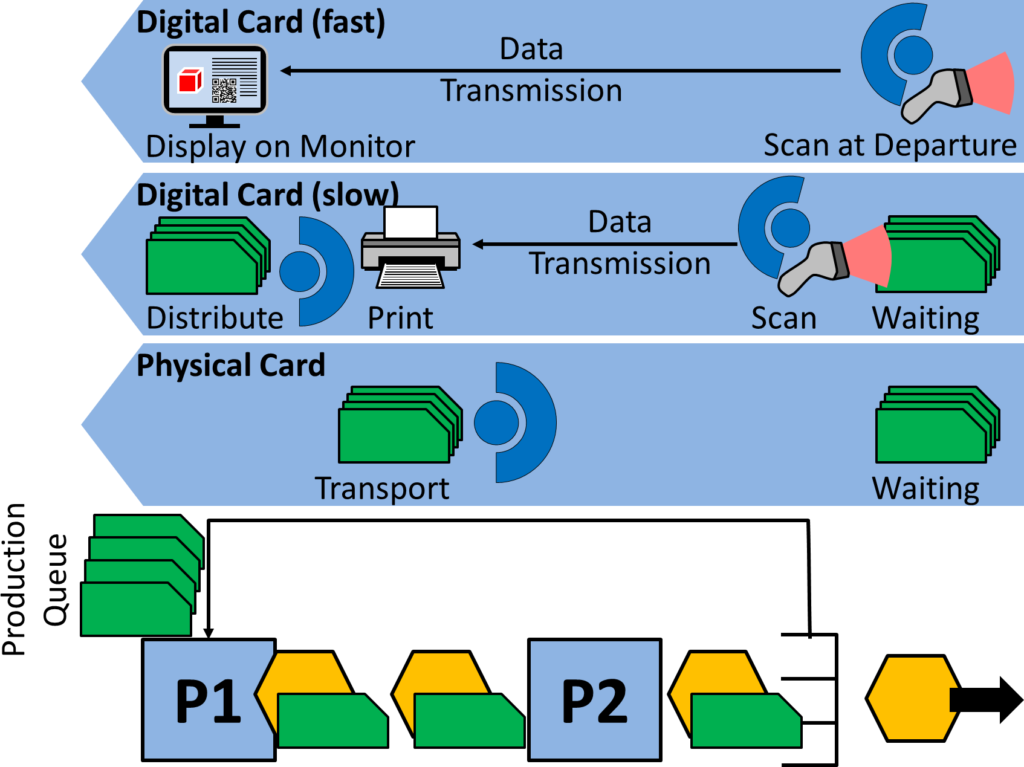

Digital information can move much faster than physical information. Hence, the digital information will always be faster – once the information is in the system. The picture may be more mixed, however, if we take the surrounding actions into consideration. Regardless if the system is physical or digital, the information starts with the removal of the part.

A physical card has to be transported back to the origin by someone. Usually the cards are collected at a post box, and transported back to the first machine at regular intervals.

For digital systems this would require the additional work of scanning (barcode, RFID chips, or similar) or typing. This may happen while the part is taken out of the inventory, or shortly afterwards for multiple removed parts as a batch. Once the data is back in cyberspace, the speed can be (almost) lightning fast. On the other end it may appear on a monitor, or as a print out, which again would have to be transported.

Depending on how the collection and distribution of this digital information is managed, the digital information may be slower than physical information. In any case, on short distances there won’t be much difference. A physical card may take one or two hours, and a digital information may also take (depending on the set-up) thirty minutes to two hours. Not too much difference for a replenishment time usually measured in days.

This becomes very different, however, on longer distances. Here the electronic transmission of data significantly outpaces that of physical data. Assuming you are receiving your goods in America by ship from a supplier in China, would you send the reorder information by postal mail? By ship this would add weeks to the replenishment time. By air it still would add days. A digital transmission, on the other hand, would be almost instant, and even with handling take only minutes or hours.

This becomes very different, however, on longer distances. Here the electronic transmission of data significantly outpaces that of physical data. Assuming you are receiving your goods in America by ship from a supplier in China, would you send the reorder information by postal mail? By ship this would add weeks to the replenishment time. By air it still would add days. A digital transmission, on the other hand, would be almost instant, and even with handling take only minutes or hours.

Hence there is a strong case to use digital transmissions for long distances. It does not have to be as far apart as America and China; even if your supplier sits in the next village over, a digital transmission may be beneficial. But before you make the decision based on the speed of the information flow alone, please note that there are more things to take into consideration.

Understanding the Situation

Another important factor is the ability to understand the current situation. Which jobs or cards are where? Here it is important to make a distinction between the manager’s view from the office and the operator’s view from the shop floor.

The manager likes to click on his computer and see the current situation in his ERP system. This works anywhere in the world as long as he has a connection to the database. This is often even the preferred way for a manager to access data, and many shop-floor-related managers spend way too little time on the shop floor.

The worker, on the other hand, wants to see the situation on the shop floor, without requiring him to log into a system that he may or may not be familiar with, or for which he may not even have access rights. Hence he prefers the physical version of information.

Managers sometimes have a tendency to see themselves as more important than the worker, and think if it is good for them, it will be good for everybody. Unfortunately, this is not necessarily true. Especially with shop-floor-related data, the people on the shop floor have a much more frequent and much more urgent need to understand the situation than a manager who may not even look at the data but insists that it must be accessible. This ties in very closely with visual management.

In sum, a physical representation of data is often much more beneficial for the shop floor where the workers frequently need to know the upcoming orders to provide material and plan the manning of the machines.

On the other hand, if there is no shop floor but only logistics, then this is somewhat less relevant. The truck driver will not open his truck to check what is loaded but rather refer to the loading papers. Hence if you are not on a shop floor, then there is much less benefit of physical data.

Continuous Improvement

Lean lives and breathes continuous improvement. As for digital versus physical information, the ability to do continuous improvement is much, MUCH easier in physical systems. Changing the handling of information (think kanban cards) is much easier if it is a paper card than if it is a digital system. Verifying your workload and inventory levels to adjust the manning or the number of cards is also much easier in physical systems.

Of course, this can also be done in digital systems. However, here you need a programmer or specialist for the digital system. And those are always in much higher demand than they are in supply. You have to get the programmer, convey him what you want him to do, and then hope that he understood what you actually wanted. Even if he got you what you wanted, you may not able to use trial and error to try things out. Usually, continuous improvement grinds to a standstill if computer systems are involved.

How About … Both?

You may be thinking, If both physical and digital systems have advantages, could I do both systems and get the advantages of both? Don’t!

Seriously, don’t do it! Obviously you will have twice the work by creating two systems. But the much bigger problem is that these two systems will have differences. The digital systems says A and the physical system says B. What do you do? The operator on the shop floor has to get a single clear signal, not two conflicting messages. While everything works in theory, the practical situation will be much more chaotic. Do your people a favor and do not have cards on top of a digital system.

Seriously, don’t do it! Obviously you will have twice the work by creating two systems. But the much bigger problem is that these two systems will have differences. The digital systems says A and the physical system says B. What do you do? The operator on the shop floor has to get a single clear signal, not two conflicting messages. While everything works in theory, the practical situation will be much more chaotic. Do your people a favor and do not have cards on top of a digital system.

It is fine to print out paper versions of the digital system, however. It is also possible but less common to scan cards to update the physical system. But only one can be the master of the data. Either the cards are just a dumb copy of the digital world, or the digital world is just a dumb counter of the physical cards. If there are differences between the systems, one of them has to give way to the other … and the physical information is more likely to be the correct one.

Summary

So, what should you do? My recommendation is to use digital information for longer distances (across different plants). This will give you a faster replenishment time, and since it is probably not a production line but a logistics process, the visual management is not quite as critical. If yours is information flow within the plant, physical information may be much easier to understand and improve. Now go out, get the information flowing, and organize your industry!

Thank you i have understand the importance of both systems, physical and elecronic Kanban and why they don’t be mixed.

Thanks for that balanced analysis. What about mixing analog and digital Kanban cards by organizing certain sub-assemblies using physical cards, such as replenishing consumables?

Hello Nikolaus, I think a mix is possible, but should be in separate sub-assemblies or lines. Having a mix in the same line has lots of possibilities for confusion.