This is my last post of a series of three posts on point-of-use providers (also known as mizusumashi, water strider, or water spider). In this post I will go into much more detail on the routing of the point-of-use provider. A less-busy point-of-use provider can handle multiple lines. Similarly, very busy lines may have multiple point-of-use providers. Here I will show you some more details on these possibilities.

Multiple Lines

Many point-of-use providers are circling around one line, with the material being supplied to a supermarket close to the line through a milk run. If the line does not need much material and the worker has a lot of idle time, he may be able to take care of the material supply for more than one line or cell at the same time. These cells should be very close to each other to avoid unnecessary walking time. Ideally, they are right next to each other. However, make sure not to overload the point-of-use provider, or your system performance will suffer.

Multiple Point-of-Use Providers

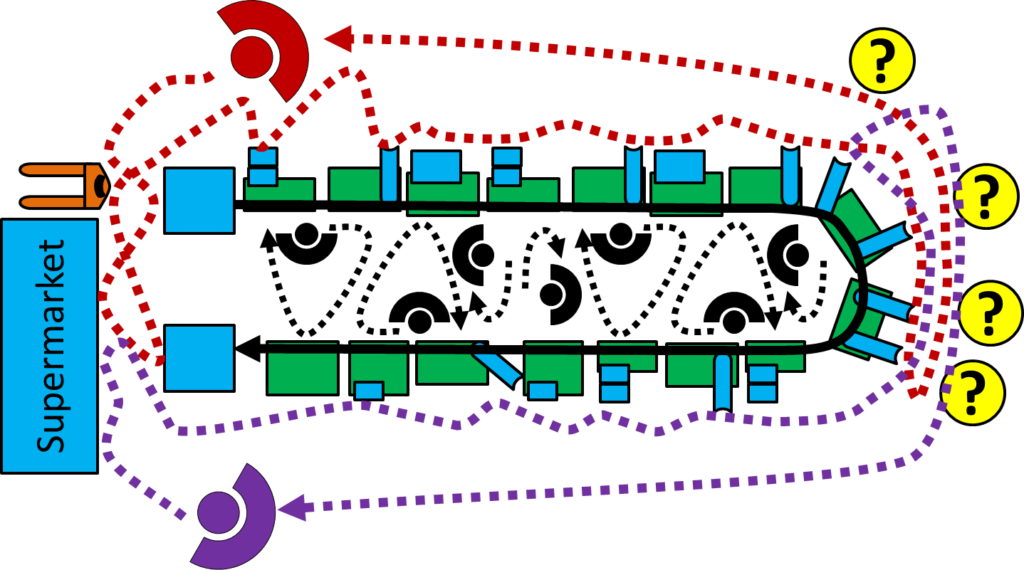

Longer and more complex lines or lines that consume a lot of material may have more work than what one point-of-use provider can handle. In this case, you can also use more than one point-of-use provider at the same time, as shown below.

Ideally, you mentally divide the line into different sections for the two point-of-use providers. While your initial impulse may be to have two segments of equal length, or (better but still not good) equal work, I would suggest creating one segment that has enough work to keep one point-of-use provider busy. The rest goes to the second point-of-use provider (or to the third, etc., if the line has work for more than two point-of-use providers). Hence one point-of-use provider will likely have significantly less work than the rest. This is good!

While ideally every point-of-use provider should have a full workload, it is better to have one of them with a lot of available time than all of them with a little bit of available time if you would divide the work equally. It is much easier to use one larger block of available time for something else than to use three small blocks. Therefore, using all but one point-of-use provider 100% makes it easier to use the remaining time of the last point-of-use provider productively for something else.

In any case, it is very important that every material location at the line is clearly assigned to one point-of-use provider only! If you don’t do that, two things are likely to happen. The first possibility is that you have one or more stations where each point-of-use provider thinks the other one will take care of it. In the end, no one is supplying the stations and they will run out of material. The line stops, the workers yell for the point-of-use providers, and some chaos ensures until it is running again. Wasteful!

The second possibility is marginally better, but still far from good. Two point-of-use providers think they both have to take care of a station. In the end, both will come to that station with material. This is redundant work, and there may not even be enough space for a double load of material. One point-of-use provider would have to bring material back to the supermarket, where the corresponding kanban already may have gone back with the milk run, which may overfill the supermarket, and so on. While the line does not stop, it also leads to some chaos. Also wasteful!

Hence, do make sure all stations are clearly assigned to the point-of-use providers. Include visual management (e.g., a blue “POU-1” sticker for stations of the first point-of-use provider, and a green “POU-2” for the second one.) Like any standard, they can optimize that over time, but do require a clear assignment.

Also, with multiple point-of-use providers you can optimize walking distance a bit. For example, if they use a pallet jack or similar to bring pallets with material to the line and pallets with completed goods from the line, it may make sense to have the same person do this work. In this case, he can bring a completed pallet back and pick up a fresh one on the way back, rather than two people doing half of that and walking empty for one leg of the trip.

Extended Point-of-Use Provider

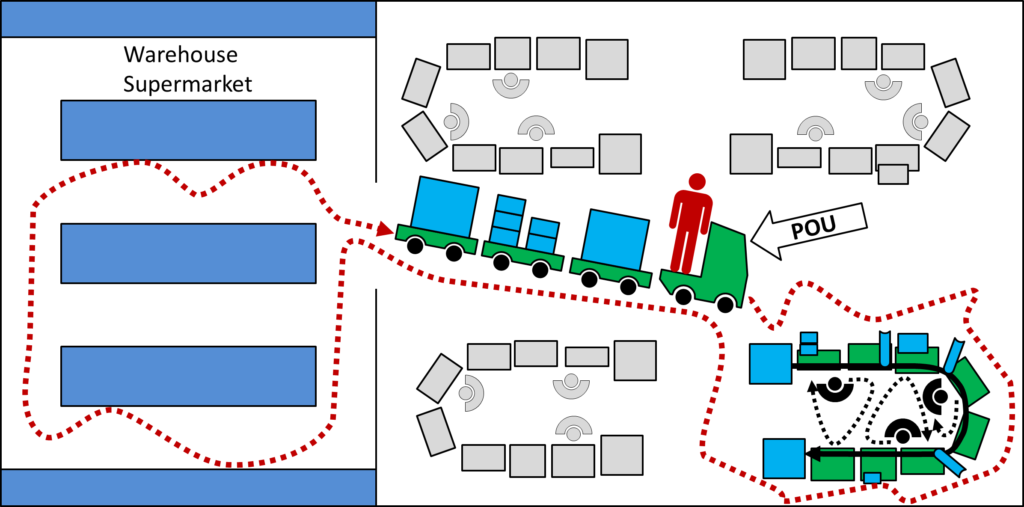

However, it is also possible to have a point-of-use provider that gets the material from a central warehouse. This is illustrated below. However, this significantly increases his walking distance. In these cases, it is highly suggested to give the point-of-use provider additional tools to help him transport more at the same time. If he would have to carry every box by hand, it would be a waste of his abilities and the line may run out of parts.

Depending on the expected material quantities needed, such a tool could be a pushcart, a forklift, or a small train similar to a milk run. In fact, the mode of transport may look and feel like a milk run, with one crucial difference! The milk run has a timetable when to drive. The point-of-use provider does not! Overall, he may have to be able to transport larger quantities than he could carry by hand.

This concludes my three-post series on point-of-use providers. I hope these were helpful to you. Now go out, get your material flowing, and organize your industry!