The point-of-use provider, also known as Mizusumashi, water strider, or water spider, is a worker that supplies material to the point of use. Similar to a waiter bringing food and drinks (and beer 🙂 ) to the customer, the point-of-use provider brings material to the workers. The latter, however, merely refills materials rather than custom orders. This point-of-use provider fulfills an important role between the inventory and the final point of use. Let me give you the details:

The point-of-use provider, also known as Mizusumashi, water strider, or water spider, is a worker that supplies material to the point of use. Similar to a waiter bringing food and drinks (and beer 🙂 ) to the customer, the point-of-use provider brings material to the workers. The latter, however, merely refills materials rather than custom orders. This point-of-use provider fulfills an important role between the inventory and the final point of use. Let me give you the details:

Introduction

Ideally, you have a pull-supplied supermarket at every location where you need material. The worker merely has to turn around and grab the part he needs for his assembly or process. Such a supermarket can, for example, be supplied with a milk run (see my extensive series of posts on milk runs starting with Introduction to Milk Runs).

The milk run is a regularly scheduled supply with fixed stops. It delivers material to supermarkets at these stops like a bus route brings people to stops on its route. However, as a bus stop is rarely your final destination, so a supermarket is rarely the final destination for material. As you may walk home from the bus stop, the material may move from the supermarket to where it is needed. You could – in theory – have a bus stop at every house, but this would slow down the bus enormously and would be very inconvenient.

The milk run is a regularly scheduled supply with fixed stops. It delivers material to supermarkets at these stops like a bus route brings people to stops on its route. However, as a bus stop is rarely your final destination, so a supermarket is rarely the final destination for material. As you may walk home from the bus stop, the material may move from the supermarket to where it is needed. You could – in theory – have a bus stop at every house, but this would slow down the bus enormously and would be very inconvenient.

The same often applies to material supply. Having many stops slows down the milk run. The difference between this and the bus example is that people can walk the last few hundred meters on their own, whereas the material needs to be carried by someone. This someone is our point-of-use provider.

The English term is self-explanatory; the point-of-use provider provides material for the point of use, sometimes abbreviated to POU. In Japanese, the word Mizusumashi (水澄まし or 水すまし) is sometimes used. This is the Japanese name for the small insects that you often find walking on lakes or ponds, the water strider. This name was chosen because the person moves around his area like a water strider on its pond.

The English term is self-explanatory; the point-of-use provider provides material for the point of use, sometimes abbreviated to POU. In Japanese, the word Mizusumashi (水澄まし or 水すまし) is sometimes used. This is the Japanese name for the small insects that you often find walking on lakes or ponds, the water strider. This name was chosen because the person moves around his area like a water strider on its pond.

As lean often uses Japanese words to sound fancier, Mizusumashi is often used even in English. The correct English translation water strider is also used as is an incorrect translation of water spider, which is not only a completely different animal, but also a different phylum from insects. The water spider also lives mostly underwater. Nevertheless, this term is also used for the point-of-use providers.

Basics for Point-of-Use Providers

The point-of-use provider takes care of the “last mile” (or more precisely last few meters) of the material transport. This is often for assembly lines, as there is a lot of material arriving. It may be not necessary, for example, in a milling or drilling process, as there is little material arriving.

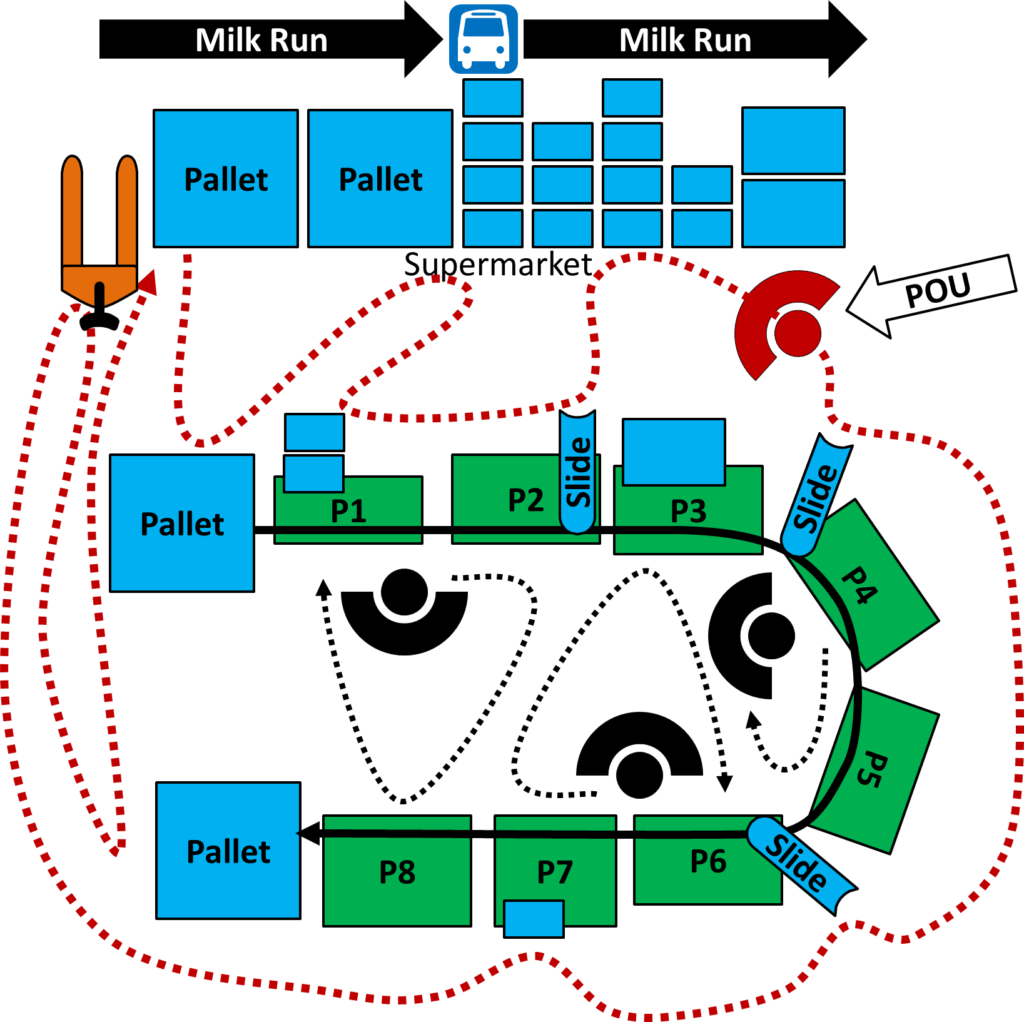

In the example below, the point-of-use provider (dark red, POU-arrow) takes material (blue) from the supermarket and brings it to the assembly line (green, U-line) so the workers can work without interruption.

- The primary objective of the point-of-use provider is to keep the workers supplied with material. Hence the workers can focus on the work and do not need to leave their post looking for material. Therefore we achieve the separation of cyclic work (the workers) and non-cyclic work (the point-of-use provider) to improve efficiency.

- The work of the point-of-use provider is not necessarily repeating itself identically. The provider does not necessarily stop at every station every time, but instead goes wherever he is needed. For U-shaped lines or cells, his route is usually on the outside of the line so he does not disturb the workers. However, it is common and recommended that he develops a regular route (i.e., circling the line). This way he can check up on every station frequently. While it is not always easy, the more repetitiveness in his route, the more efficient he will be. Over time he will get his routine and optimize his walking distance, but it is very difficult to pre-describe a fixed route. Ideally, he will also develop his own standard that he can repeat. I find that with this standard he usually does a better job over time than a manager who writes him a standard at the beginning. But do not forget to give him the task to optimize himself.

- The material is supplied by other processes, ideally milk runs, into a supermarket for the line. This supermarket should be not too far from the assembly line. There may be more than one supermarket for longer lines.

- Whenever he removes material from the supermarket, he puts the kanban card into the kanban box, or – if the box is the card – returns empty boxes. If the box or kanban goes from the supermarket to the actual line, make sure that you include this additional distance – or more precisely its time – for the calculation of the replenishment time and subsequently the number of kanban in the loop.

The point-of-use provider carries lighter material by hand, while heavier material may require a pallet jack, pushcart, or similar device, which should be readily available for him and ideally not a shared device.

The point-of-use provider carries lighter material by hand, while heavier material may require a pallet jack, pushcart, or similar device, which should be readily available for him and ideally not a shared device.- He may repackage items to make it easier for the workers. For boxes he may remove lids or packaging. Smaller items like screws may be taken out of the box and added to, for example, a slide or chute to optimize the material for the worker. He may also wrap completed products, for example by securing a pallet using plastic wrap.

Yes, It Is Pull!

The material supply through a point-of-use provider is usually a pull system. If the boxes are the kanban, it is automatically a pull system. But even if the point-of-use provider repacks the material and removes the kanban, it is still pull.

The material supply through a point-of-use provider is usually a pull system. If the boxes are the kanban, it is automatically a pull system. But even if the point-of-use provider repacks the material and removes the kanban, it is still pull.

First of all, do not create an additional kanban loop between the supermarket and the assembly line. The effort would heavily outweigh the benefit, making the whole idea pointless. Instead, the point-of-use provider is close enough to the line to keep an overview about what is needed. Rather than handling additional kanban cards, his job is merely to fill up the material at the line to its target levels. As there is usually only a small number of parts involved, the point-of-use provider can simply memorize what is needed. If on his route around the line he sees a material that is getting low, he only has to memorize it until he arrives at the supermarket and picks up more material. This can be done usually by memory and does not require an additional kanban card or similar.

However, it does require a clearly defined material inventory at the assembly line. This material has to last until the point-of-use provider can resupply material. Often, a two-bin system is good enough, and the point-of-use provider merely replaces an empty bin while the worker takes parts from the other bin. If the material is in a slide or chute, the chute should also contain enough material until the point-of-use provider can refill the chute. As always with pull inventories, you may make the inventory a bit larger to add some safety buffer.

This post gives you a brief overview on point-of-use providers (also known as water spiders, water striders, or Mizusumashi). However, there is more on the topic. As so often happens, I wanted to write a single blog post on a topic, and I ended up finding enough things to cover for three blog posts. Hence there are two more. In my next post I will go a bit more in detail on the calculation of the workload … although with the quality of the data that is usually available, it is much less a calculation and more of an educated guess. In my last post I will talk about the routing of the point-of-use provider. Now, go out, get your material flowing, and organize your industry!

I understand your use of the term “point of use” but I would like to draw your attention to loose usage in the US, where I have heard storage locations 30ft away from an operator workstation referred to as “point of use.” All it meant was “not in the central warehouse” and I don’t think it’s what you mean.

Hi Michel, true, I mean the point where the part is actually consumed/built into another part. As all so often, the language in lean is far from being standardized. “Point of Use” is common in Germany, or at least it is the standard term at Bosch where I used it a lot. Thanks for pointing that out.

Hello Chris,

I understand what you said how I can implement POU in a push system in Production environment.

Hi Anshuman, POU work best in pull, but you may be able to make it work in push, although material availability will not be as good.