Job Relations (JR) is one of the modules of the original Training within Industry (TWI) program. It was actually developed at Harvard using case studies, and for its time was groundbreaking in its idea that leadership can be learned! Like most TWI modules, it is sensible and useful. As with most TWI programs, it is focused on the front lines of the shop floor, and designed for first-line and second-line supervisors. The module is about good shop floor leadership.

Job Relations (JR) is one of the modules of the original Training within Industry (TWI) program. It was actually developed at Harvard using case studies, and for its time was groundbreaking in its idea that leadership can be learned! Like most TWI modules, it is sensible and useful. As with most TWI programs, it is focused on the front lines of the shop floor, and designed for first-line and second-line supervisors. The module is about good shop floor leadership.

While the program dates from World War II, it has lost none of its relevance, and can still help modern-day shop floor managers in becoming better leaders. The steps are not rocket science, but good common sense, and described with a clarity and brevity unusual for a management book. Below is a summary, mostly condensed from the “Job Relations 10 Hour Sessions Outline and Reference Material.” This is the third in a series of five posts on TWI.

The Fundamentals

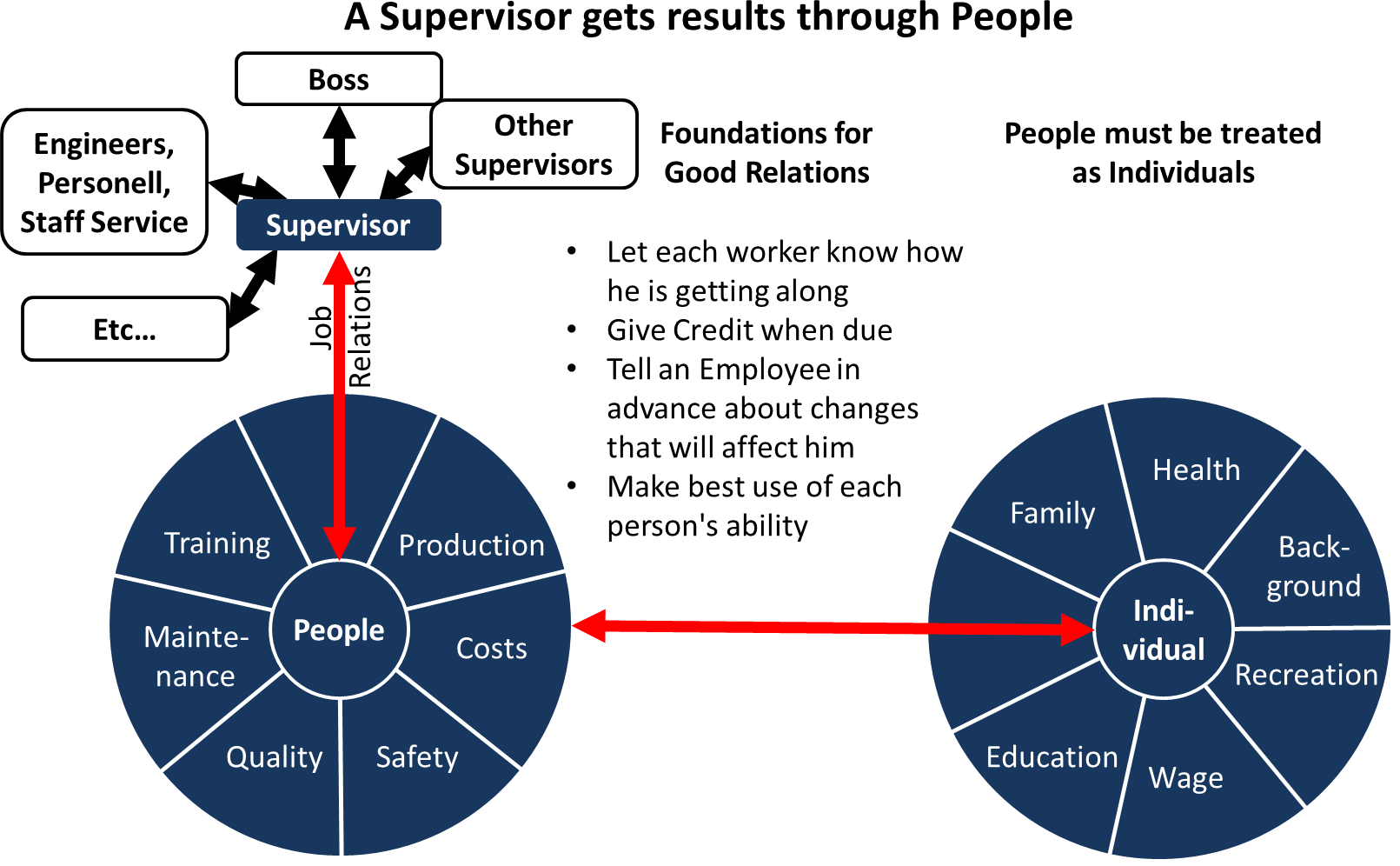

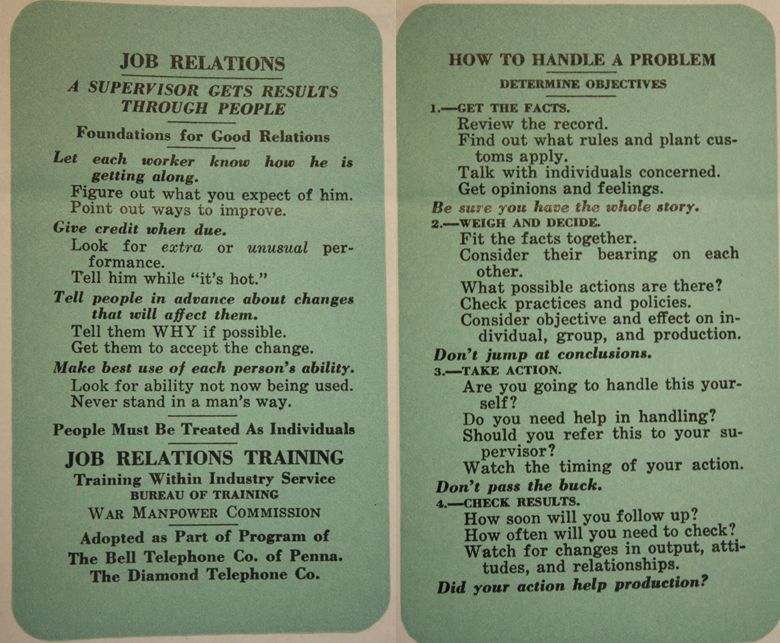

Again, let me start with the fundamentals. These were printed on small cards, and represent the basic steps of good management. One of the cards is shown below. Most important is the first line: A supervisor gets results through people! The steps handle two issues: first, how to establish good relations with your people (proactive), and second, how to handle disputes (reactive). Here are the basic rules of job relations:

Foundations for Good Relations

- Let each employee know how he is getting along: Find out and tell him what you expect. Point out ways to improve.

- Give credit when due: Recognize extra or unusual performance. Tell him while it’s fresh.

- Tell an employee in advance about changes that will affect him: Tell him WHY if possible. Get him to accept the change.

- Make best use of each person’s ability: Look for ability not now being used. Never stand in an employee’s way.

People must be treated as individuals!

How to Handle a Problem

Determine Objectives

- Step 1: Get the facts: Review the record. What policies, rules, regulations apply? Talk with individuals concerned and get opinions and feelings. Be sure you have the whole story.

- Step 2: Weigh and Decide: Fit the facts together and consider their bearing on each other. What possible actions are there? Check each action against objectives, weighing effect on individual, group, and production. Select the best action.

- Step 3. Take Action: Should I handle this myself? Who can help in handling? Should I refer this to my supervisor? Consider prompt time and place. Explain and get acceptance. Don’t pass the buck!

- Step 4: Check Results: How soon and how often will I check? Watch for changes in output, attitudes, and relationships.

Did my action help production? Were objectives accomplished?

On Leadership…

Leadership is tough. There are often many conflicting objectives, insufficient data to know things for sure, and lots of employees and other stakeholders wanting different things from you – or even challenging your leadership. The challenge of leadership is getting all of these at least somewhat aligned. The TWI manual states the following as the demands on a good leader, but here I took the liberty to add a part that I believe is very important (in italics):

Leadership is tough. There are often many conflicting objectives, insufficient data to know things for sure, and lots of employees and other stakeholders wanting different things from you – or even challenging your leadership. The challenge of leadership is getting all of these at least somewhat aligned. The TWI manual states the following as the demands on a good leader, but here I took the liberty to add a part that I believe is very important (in italics):

Good Leaders get the people in the department to do what he wants done, when it should be done, and the way he wants it done, because they want to do it, and also gets them to improve what they are doing!

Below is the chart that TWI used to show these relationships.

Common Pitfalls

There are a few common pitfalls in understanding men, where the supervisor (or others) judge prematurely. The Job Relations manual lists the following:

There are a few common pitfalls in understanding men, where the supervisor (or others) judge prematurely. The Job Relations manual lists the following:

- The “Die Casting” habit: We try to sort a person in a certain category in our minds, and have difficulty adjusting that if the behavior or facts change.

- The “Just Like” habit: This is similar to the “die casting habit,” but instead of a category we compare him to another person who he is “just like.“

- The “Go, No-Go” habit: Quickly sorting a person into one of two categories like can/cannot do, useful/not, good/bad.

- The “Formula” habit: Dealing with a type of person (see the above habits) in a stereotypical manner. While this can be useful, excessive use should be avoided.

- The “Standardization” habit: Treating people like a standard commodity (he is a welder), and ignoring special abilities and interests (he is good at optimizing the welding settings). Often these particularities will make a worker especially useful.

Understanding Your People

The manual looks at certain aspects in understanding a worker. Please note that issues with most of these points below could be also a failure of management rather than the worker. In fact, it may be more likely to be a management shortcoming than a worker failure.

The manual looks at certain aspects in understanding a worker. Please note that issues with most of these points below could be also a failure of management rather than the worker. In fact, it may be more likely to be a management shortcoming than a worker failure.

- To what degree is he doing a good job? Please note that this may also be a shortcoming on the training by the supervisors.

- Does he fail to understand the instructions? This could also be a training issue.

- Does his attention wander from the job?

- Is he interested in his job? Understanding the reason for his job and recognition are two important points here.

- How does he respond to recognition?

- Does he stand on his own feet? If not, give him more confidence.

- Does he seem ill adapted to the job? If he is a misfit, it may again be a training issue. Also, being unskilled in one job doesn’t mean that he is unskilled for everything.

- Does he get along well with the other people in the department?

The manual showed a couple of examples. Interestingly enough, one of the examples was about promoting a woman to supervisor, which would be the first female supervisor in the plant. The woman was selected only because no qualified man was available.

The manual showed a couple of examples. Interestingly enough, one of the examples was about promoting a woman to supervisor, which would be the first female supervisor in the plant. The woman was selected only because no qualified man was available.

Luckily, this is one of the things that have changed since 1945, and female management is no longer an issue, although still far from 50% of the managers on the shop floor.

Summary

The points above are fundamentals and basics of good leadership, both for good times as well as during disputes. Nothing fancy here, but solid good leadership basics will often go a long way. I found these notes rather helpful, although I would put a bigger focus on improvement. TWI does this with the Job Methods, but I would have liked to see a bit more of kaizen already in the job relations. But, apart from that it, is a pretty useful standard approach.

Will it solve each and every problem? Probably not, but it will definitely help with many issues arising on the shop floor. Management will continue to be difficult, and you won’t be able to make everybody happy, but it has to be done. Doing it well is a major step toward a good factory. Now, go out, look at your people – and I mean really look and understand them, go through the Job Relations card, and organize your industry!

P.S.: Many thanks to TWI Guru Mark Warren for checking the text.

Series Overview

- Training within Industry – TWI – Oldies but Goldies

- JI: Training within Industry – Job Instructions

- JR: Training within Industry – Job Relations

- JM: Training within Industry – Job Methods

- More on TWI Programs

Sources

War Manpower Commission. 1944. “Job Relations 10 Hour Sessions Outline and Reference Material.” War Manpower Commission.

War Manpower Commission. 1944. “Job Relations 10 Hour Sessions Outline and Reference Material.” War Manpower Commission.