Supplying material for assembly operations can be quite a challenge. After describing the challenges in the previous post, I would like to show you in two posts what you need to consider when you want to create an assembly location. This is a somewhat structured approach on how to set up a material supply for your assembly operations, although you will still need some iterations to achieve a good solution. After that I will have a post focused on what to do if you are running out of space at your assembly location.

Supplying material for assembly operations can be quite a challenge. After describing the challenges in the previous post, I would like to show you in two posts what you need to consider when you want to create an assembly location. This is a somewhat structured approach on how to set up a material supply for your assembly operations, although you will still need some iterations to achieve a good solution. After that I will have a post focused on what to do if you are running out of space at your assembly location.

Approaches to Assembly

The following is a list of methods and ideas. Not all of them will work for your case, but do consider what is suitable for your situation. The task on how to distribute a more complex assembly among different stations would exceed the scope of this post. In previous posts I also already explained line layout strategies, pacing of flow lines, and different ways of organizing workers (bucket brigade, chaku chaku, rabbit chase). Now we will be looking at only one station.

The following is a list of methods and ideas. Not all of them will work for your case, but do consider what is suitable for your situation. The task on how to distribute a more complex assembly among different stations would exceed the scope of this post. In previous posts I also already explained line layout strategies, pacing of flow lines, and different ways of organizing workers (bucket brigade, chaku chaku, rabbit chase). Now we will be looking at only one station.

Please note that this is unfortunately not a simple checklist that you have to go through, but rather an iterative process. I have sorted the steps by sequence as well as I can, but you will probably quite often have to go back to change a previous approach in order to make the assembly work.

What Parts Do You Need?

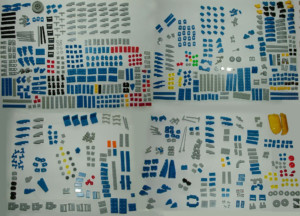

First you need to figure out what parts you need for your assembly. This list has to be complete. Be aware that this is not only the list for one product variant, but for all product variants that have to pass through this station, including packaging and other stuff. You will end up with a list of parts that have to be accessible for the operator to do his work. In all likelihood, a number of database queries will give you the (hopefully correct) data.

First you need to figure out what parts you need for your assembly. This list has to be complete. Be aware that this is not only the list for one product variant, but for all product variants that have to pass through this station, including packaging and other stuff. You will end up with a list of parts that have to be accessible for the operator to do his work. In all likelihood, a number of database queries will give you the (hopefully correct) data.

What Tools Do You Need?

Rarely does the worker assemble parts without tools. These also have to fit at and around the workspace. Especially for heavy or delicate parts, you may need special equipment. Do you have to install a crane or lifting device, or does the worker need tweezers?

Rarely does the worker assemble parts without tools. These also have to fit at and around the workspace. Especially for heavy or delicate parts, you may need special equipment. Do you have to install a crane or lifting device, or does the worker need tweezers?

How Many Parts Do You Need?

You should also know how much of these parts you need in a certain time frame. This is not only the number of parts that go into one product, but how many of these parts you need per hour of operation. It is important for the material supply to know how many parts to store at the assembly location to ensure an uninterrupted supply.

You should also know how much of these parts you need in a certain time frame. This is not only the number of parts that go into one product, but how many of these parts you need per hour of operation. It is important for the material supply to know how many parts to store at the assembly location to ensure an uninterrupted supply.

Important: This must not be the average, but the peak demand! If you need, on average, eight flux capacitors per day, it would be one per hour on average for an eight-hour workday. However, if you produce in batch sizes, all of these may be needed within one hour. Hence you have to plan for the peak demand on your parts, not the average.

Okay, now you know your average demand. This has to be combined with the frequency of your material supply. If you need ten parts of one type per hour, and your material supply comes along every thirty minutes, you need to keep five parts (plus some safety) at the assembly station for uninterrupted work. If you material supply comes along only every two hours, you now have to fit twenty parts at your station. You can see how a more frequent delivery reduces the number of parts required.

Okay, now you know your average demand. This has to be combined with the frequency of your material supply. If you need ten parts of one type per hour, and your material supply comes along every thirty minutes, you need to keep five parts (plus some safety) at the assembly station for uninterrupted work. If you material supply comes along only every two hours, you now have to fit twenty parts at your station. You can see how a more frequent delivery reduces the number of parts required.

Your delivery can also be regularly scheduled, often called a milk run, or it can be by demand. Please note that the on-demand supply works best if the person supplying is closely connected to the assembly line. If it is just one of your many forklift drivers, chances are that occasionally your assembly will be missing parts.

Your delivery can also be regularly scheduled, often called a milk run, or it can be by demand. Please note that the on-demand supply works best if the person supplying is closely connected to the assembly line. If it is just one of your many forklift drivers, chances are that occasionally your assembly will be missing parts.

Overall, you have to make sure that the worker does not run out of parts even during peak load and even with a minor delay on the material supply (if the material supply is delayed more, eventually the worker will run out of parts).

What Are the Properties of Your Parts?

For all parts needed, you have to figure out more details on the parts. Important aspects are, for example:

For all parts needed, you have to figure out more details on the parts. Important aspects are, for example:

Packaging Type: What packages do your parts come in? Is it a plastic box that has to be returned? Is it a cardboard box that has to be scrapped afterward? Depending on the type of packaging, you may have to handle the part differently.

Packaging or Part Size: How big is the part or a set of parts including the packaging? This determines the size needed to store the parts.

Weight: How much does the part weigh? Light parts can usually be installed easier. Heavier parts are more difficult. Keep in mind that the worker does not only have to do it once, but many times. Also keep in mind that workers have different strengths, and what may be easy to life for a man may be more difficult for a woman. Here you should involve an ergonomic expert.

Handling issues: There are other things that may be relevant for assembly. Is the part spiky or does it have sharp edges? Your workers may need gloves to protect themselves. Is the part washed and fat-free? Your workers may need gloves to protect the part from fingerprints. Is the part sensitive to static charges? Your workers may need ESD clothing. Is the part very small? Your workers may need tweezers and magnifying glasses. There maybe more requirements, and it is probably best to involve shop floor people to find these things out. (You should involve shop floor people in the entire process, by the way. This will give you much better results.)

Due to the length of this post, I had to split it into two. In my next post I will continue on how to fit parts around your stations an touch briefly on ergonomics and how to provide material. We should also not forget the necessary information flow and safety aspects. Until then stay tuned, go out and organize your industry!

GREAT READ – simply put…thats what LEAN is about

I started to think what is for lean optimal product structure, shoul all material be on one structure, can it be easier to have products bill of material with many sub-assemblies. Or let me ask this way when it would be beneficial to group material in to sub-assembly and when this is just waist?

Hi Lazzy, sub-assemblies are useful if you have a component that can be assembled separately. E.g. lots of parts go in a car. But you would not assemble the engine on the same line as the car but separately. This should be pretty obvious if you assemble a product. Doing a subassembly by the same person at the same line is often not ideal.