Karakuri is the art of creating machines without an external power source. After an introduction to the topic in my last post, I would like to show you some fundamental techniques for karakuri.

Karakuri is the art of creating machines without an external power source. After an introduction to the topic in my last post, I would like to show you some fundamental techniques for karakuri.

I would like to pay particular attention to power management: Where do these machines get their power from, how do they store it, and where does it go? I will also (very !) briefly talk about kinematics, and even some karakuri ideas that go beyond kinematics. My next post will have lots of examples, mostly from the Karakuri Kaizen Exhibition 2017 in Nagoya.

Power Management

A karakuri device needs power to function, or, more generally speaking, it needs energy. Rather than using a dedicated power source like a motor, karakuri devices take their energy wherever they can get it from. Here are some examples of where to get energy, how to store it, and how to get rid of it.

Energy Sources

Often, the energy source is human muscle. Many karakuri devices are operated by hand, like a lever or a pair of custom pliers. This can also be in an indirect form (i.e., when the worker takes a power tool out of a holder or returns it, the movement of the power tool can power a mechanism). Many other karakuri devices are operated by stepping on a lever or pedal. This provides more power as the muscles in the leg are stronger. The biggest human energy source for the largest energy demands is created when the person steps with his full body weight on a platform. See the video below for an example of a lever operated karakuri by ITEM.

Often, the energy source is human muscle. Many karakuri devices are operated by hand, like a lever or a pair of custom pliers. This can also be in an indirect form (i.e., when the worker takes a power tool out of a holder or returns it, the movement of the power tool can power a mechanism). Many other karakuri devices are operated by stepping on a lever or pedal. This provides more power as the muscles in the leg are stronger. The biggest human energy source for the largest energy demands is created when the person steps with his full body weight on a platform. See the video below for an example of a lever operated karakuri by ITEM.

Another energy source is taking away a bit of energy from another machine. The movement of another machine is utilized to power the karakuri device. For example, a material supply cart driving by a storage rack may activate some levers within the rack.

Closely related is the use of gravitational energy. A heavy object moves downward and powers the mechanism. This could be the part rolling down a slide and activating other mechanisms, as seen for example in the Toyota kaikan video above. Especially if you are moving your products using their own weight, you have to get as much usable movement as possible for the decrease in height, otherwise you soon have to make holes in the floor. I have also seen a heavy metal ball rolling downward to release stored energy and to move a cart forward where the object on the cart could not drop in height by itself.

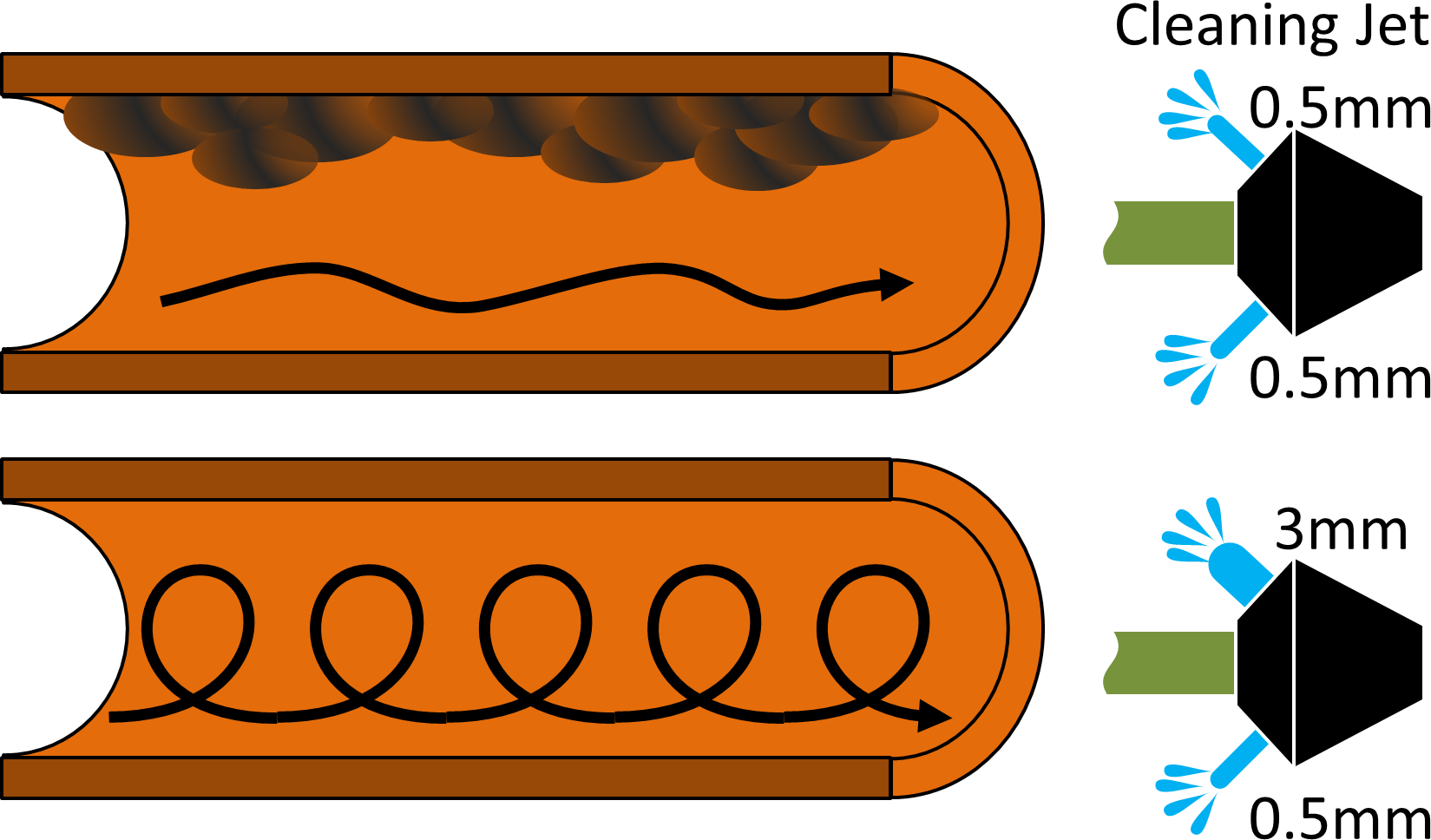

I have also seen water jets as an energy source. The Suntory brewery directs a water jet at a small propeller to rotate a filter during cleaning, where lots of water jets are spraying on the filter anyway. Aisin Takagaoka is cleaning the inside of pipes using water jets from a nozzle that also propels the nozzle forward. Their problem was that this cleaned only the lower part of the pipe. After introducing an imbalance in the nozzle by making some jets larger than others, the nozzle now tumbles through the pipe and also cleans the upper part of the pipe.

Similarly, wind power can also be used. A very easy and common example would be plastic strips at air vents. If the strip is moving, the vent is venting. If not, then not. However, this would be difficult for an intake vent, in which case I have seen small toy propellers installed at the vent. A rotating propeller indicates air flowing in.

Energy Storage

For many karakuri devices, you would have to store energy. Here too you can find a number of different ideas.

Very common is a type of seesaw. One thing moves down (releases gravitational energy), while another thing moves up (stores gravitational energy). Later you can use this stored gravitational energy when the first thing has left the device.

Closely related are weight on strings. During a movement, this weight is pulled up. Later, this weight is released again to provide energy. Often, these weights were plastic bottles or canisters filled with water or sand, which allows easy fine-tuning of the weights.

Yet another ingenious way of strong energy is a pendulum. One example I have seen used the removal of a power screwdriver from its holder to set a pendulum in motion. This was then converted into rotational movement that powered a magnetic disc that took screws out of a storage container, oriented them, and put them in a small buffer for the worker to use. The pendulum stored just enough energy to get five to six screws, which was all what the worker needed.

Naturally, you can also wind up springs, as for example in the Toyota Kaikan video above. Rubber bands also work.

Besides weight, energy can also be stored as a momentum. An object rolling forward can activate a lever simply through its momentum. This momentum can be linear or angular. Such, a flywheel, sufficiently large, can power an entire bus.

Energy Dissipation

Not as common but still sometimes necessary are devices to get rid of excess energy. You simply convert the movement into heat through friction. These could be brakes, oil dampers, or similar. Usually this is not much of a challenge.

Principles of Movement

If you have ever taken a fundamental kinematics course and wondered when you will ever need those kind of contraptions, well, for karakuri you do! To cover all the things that are possible would by far exceed the scope of this blog (and would not really be my area of expertise either). Hence, here is only the briefest of introductions.

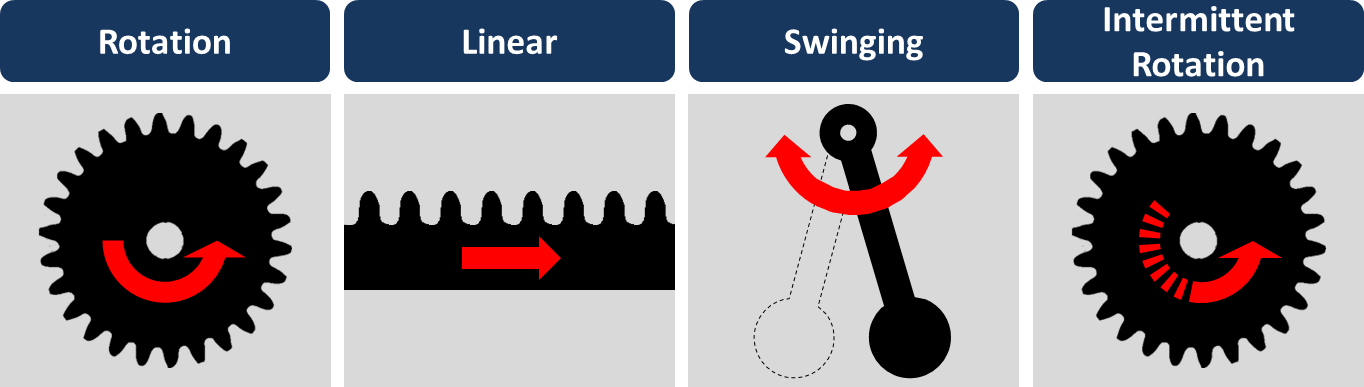

You convert movement from one form into other forms. Besides changing directions, this means converting back and forth between rotational movement, linear movement, swinging, and intermittent rotation. There will be all kinds of gears, ropes, pulleys, cams, cogs, bars, links, belts, and whatnot. For more inspiration, see the Wikipedia Category:Hardware (mechanical) or Category:Kinematics, or just pick up a good kinematics textbook.

One particularly neat idea (at least to me) was a small set of four gears that converted omnidirectional rotation into unidirectional rotation as shown in the video below.

Beyond Kinematics

Of course, you are not limited by kinematics either. Many karakuri mechanisms use magnets. Others use water jets as described above. I have even seen an example by Denso where they used an karakuri mechanism to activate a syringe that created enough vacuum suction for a suction cup to transport a computer chip. I will write more about such examples in my next post. This is the right time to be creative! Now go out, think out of the box, get your gears moving, and Organize your Industry!

Another very good article, remembrances fundamental to create energy sources that will be applied for Karakuri understanding. I am expecting for next post with examples, as you said, mostly from the Karakuri Kaizen Exhibition 2017 in Nagoya. Many thanks for sharing.

Very good explanation to provide understanding about Karakuri Kaizen.

More of practical examples working in the industry will help further.

Thank you.

Could be possible to get bibliography about technical of karakuri, where to learn the systems a learn the mechanical concepts?

I don’t have any books on Karakuri Kaizen in particular. However, there are lots of books on kinematic and mechanics, which – although not labeled “karakuri” – are relevant here. I don’t have any particular book to recommend.