This third and last post on Just in Sequence details all the things that can go wrong, and talks about how to fix them. The biggest problem is if the sequence of your Just in Sequence part does not match the main component that it should be sequenced to. This happens especially due to defects and rework. I also describe common options to deal with these problems – but be warned: all of them suck. As usual in lean, it is so much easier not to have problems in the first place than it is to deal with them afterward.

This third and last post on Just in Sequence details all the things that can go wrong, and talks about how to fix them. The biggest problem is if the sequence of your Just in Sequence part does not match the main component that it should be sequenced to. This happens especially due to defects and rework. I also describe common options to deal with these problems – but be warned: all of them suck. As usual in lean, it is so much easier not to have problems in the first place than it is to deal with them afterward.

Don’t Break Sequence

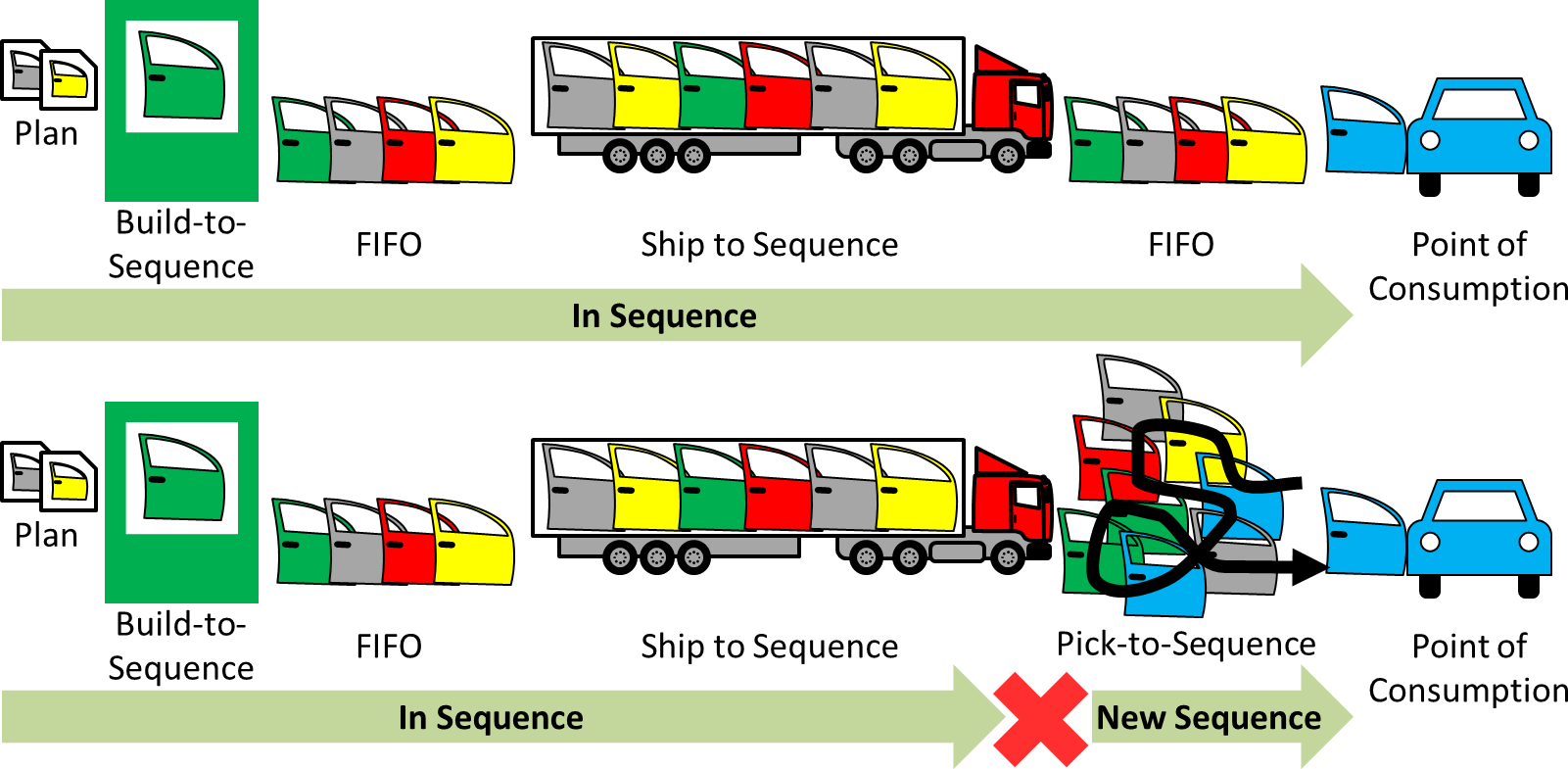

One thing you have to watch out for in sequencing is that you need to maintain sequence from the point where you create the sequence until the point of consumption. If you break the sequence anywhere in between, then your effort is wasted and you have to pick the sequence again. This means that the entire material flow from the creation of the sequence has to be one big FIFO lane. In fact, FIFO is pretty much the only good way to store material for Just in Sequence. Don’t use supermarkets or random inventory, as they will break the sequence again.

Causes of Sequence Differences

Like anywhere, mistakes do happen. At one point you will find that the sequence of the component will no longer match the sequence of the main product. There are a few main causes of such a mismatch.

Wrong Part Sequenced

Less commonly, there is a mistake when creating the sequence. The image illustrates this by showing a red door for a yellow car. When creating the sequence, they picked/produced/delivered a red door where they needed to provide a yellow door.

Less commonly, there is a mistake when creating the sequence. The image illustrates this by showing a red door for a yellow car. When creating the sequence, they picked/produced/delivered a red door where they needed to provide a yellow door.

Part Removed for Rework/Defect

More commonly, however, a part is taken out of the line due to defect or rework. This can happen for either the sub-component or the main component. As a result, the sequence of the other products is now out of line. Less commonly, there is a mistake in the sequence.

Take, for example, this image. Assume the yellow car had a problem and had to be taken out of the line. Now, the sequence of the doors (and any other products in sequence) no longer fits.

Take, for example, this image. Assume the yellow car had a problem and had to be taken out of the line. Now, the sequence of the doors (and any other products in sequence) no longer fits.

The yellow doors have no matching car, and if you just follow the procedure, the next gray car will have yellow doors, whereas the gray doors intended for that car will be with whatever color the car has after the gray one.

Part Missing

Yet another cause for a sequence mismatch is a missing part. This is particularly dangerous, because if you do not catch that in time, all subsequent products will have a wrong part installed!

Yet another cause for a sequence mismatch is a missing part. This is particularly dangerous, because if you do not catch that in time, all subsequent products will have a wrong part installed!

In the example here, the green right door is missing. If that is not detected in time, the green car will get the next door in line, which happens to be yellow. The yellow car for which the door was intended will get the next door, which happens to be gray, and so on. Every subsequent car will have the wrong door until the problem is corrected.

What to Do with Sequence Differences

To remedy these sequencing issues, you have a number of options. All of them suck.

Replace Wrong Part

Option one is to replace the one part that is wrong. For the two examples above, you could take out the red right door and add a yellow right door, or you could substitute another yellow car body for the one taken out for rework.

Option one is to replace the one part that is wrong. For the two examples above, you could take out the red right door and add a yellow right door, or you could substitute another yellow car body for the one taken out for rework.

The problem is: Where do you get a right yellow door (or a yellow car body) on short notice? In all likelihood you won’t have this part available, so this is usually not an option. Even if you have the part, it may be difficult to “pop it in” the line. How do you move a car body in and out of an assembly line except at its beginning and end? However, if you happen to have the part available, this may be the easiest option.

Remove All Parts in Wrong Sequence

The second option is to take out all parts related to the sequence difference. For the example above, you would remove the yellow car body and the yellow left door (all in correct sequence) as well as the mismatched right red door.

The second option is to take out all parts related to the sequence difference. For the example above, you would remove the yellow car body and the yellow left door (all in correct sequence) as well as the mismatched right red door.

In effect, an entire product with its sequenced components is taken out of the line. Naturally, the more parts you have sequenced, the more hassle this is (think seats, dashboard, steering wheel, etc). And again, it may not be easy to remove these parts from the line. For example, to remove the main body, you probably would have to halt the main assembly line, idling hundreds of workers for 10 minutes at a cost possibly exceeding the value of the car in the first place. Usually not really a good option. And keep in mind, you not only have to do this physically, but also in your computer system! Any error, and you will just have produced even more mismatches for the near future.

Just Build It As Is

The next option is to just build it as is. No matter what comes down the line, you build it. If you happen to have a red door for a yellow car, then by all means assemble the red door to the yellow car. This is the least disruption for the assembly process.

Obviously, you can’t sell that to the customer. Instead, you have to fix the product afterward during rework. This means taking the product aside, obtaining a matching new part (i.e., a yellow right door), removing the mismatched part (the red right door), and attaching the yellow door. This is obviously not good for the doors or the cars. If it is a product deeper inside of the car, you may have to remove many other parts to get to it (e.g., you may have to remove the doors and seats to replace the dashboard). Again, a major hassle, but for many automotive companies that is the option they go for.

Of course, this works only if there is “only” a wrong part somewhere in the sequence. If a part is completely missing in the sequence, then all subsequent parts move one slot forward, and hence all products after the missing parts have a mismatch and would need rework.

Keep Things on the Line, But Don’t Assemble

A final option is to keep all parts in the line, but don’t assemble mismatched parts. For example, the yellow car in the examples above would move along the line and get its yellow left door attached but not the erroneous right red door. The red door is put aside and you have a car moving along the line missing a door. Later, a correct door is installed during rework.

This sounds easiest, but it also has its problems. Any other part attached to this “non-attached” part has to remain unattached. There are a number of problems with this.

First, it confuses the people on the assembly line. If you job is it to attach door handles to the doors, and a car comes along without doors, then it will be confusing and break your rhythm (if it happens so often that you are used to it, then that is not good either 😛 ).

Second, you also have the problem of what to do with the parts at hand. Eventually they have to go to the rework area and find their matching car again. Hence, you have to create a separate material flow on the fly for just this one car. Since there is probably no standard for it, it depends on the worker’s ability if this handling of the unused part works well or not. The worker has to find a place for the part(s), inform someone from logistics, who has to bring it to the rework area, find the matching car, and find a place to store it there. What could go wrong?

Finally, you need to keep track of what has been assembled and what is missing. For rework, you need to obtain all the missing parts (which you hopefully somehow got from the worker that had it in excess). There is also the risk of forgetting something, resulting in a potentially incomplete car being shipped to the customer. Overall, it is a possibility, but it also sucks. Often, the “just build it as is” could be the best option. Of course, not making any mistakes in the first place would be even better.

This concludes this three-post series on Just in Sequence. As all so often, I wanted to write a brief one-post article on Just in Sequence, but with all the details involved I ended up again with a three-post series and over 4,000 words. Thanks for staying with me in this lengthy process. Now, go out, see if your plant is suitable for sequencing, if so do it, and organize your industry!

Great post Christopher. I´ll think in your recommendations the next time I´ll plan a JIS delivery system.

P.S.: Are you able to give a discount cupon for your loyal blog readers to buy your book at Aamazon? 🙂

Hi Guido, all the pricing on my book “Faster, Better, Cheaper” is controlled by the publisher. I could suggest checking a local library. WorldCat has a good library search function.

Hi Christ, I agree with you regarding the real benefit of “Just in Sequence”: reduction of handling. From my experience inventory could be reduce in some sections of the value stream but some suppliers will need to absorb it (consignments) as result the extra cost will be reflected in final price. Nevertheless If the cost of the component is “high” the positive impact in your cash flow could be significant.

As you suggested “Just in Sequence” can be applied to parts with high variety such as wire-harness, steering wheels, etc. The big burden in many companies will be in the IT side and “surprises” due to the lack of understanding about the roles of many indirect functions.

Just in Sequence can have challenges such as two suppliers “Building in Sequences” and one supplier consolidating both products and “Shipping to Sequence” . A really “complex scenario” just considering the IT-requirements from suppliers and customer. This can be the case when one supplier produce 80-90% of the models and the second supplier produce the rest (exotics).

Finally, the high tendency of German OEMs to customize their product is adding pressure on suppliers not use to produce in sequence creating new challenges in the industry.

Hi Freddy, sequencing (and leveling in general) can be done by pushing the buffer inventories to the supplier. But, as you said, this moves only the problem elsewhere. The real art is to have the supplier not only deliver but produce JIT! Of course, this requires the fixing of the production plan quite a bit ahead of time, something many western companies can’t manage well.

Wow, Fentastic write up on the JIS, that starts from the Prerequisite till the post implementation problems & its solution, the person who don’t even know what is JIS also can understand, with the given picture illustrations, Great Work..!!!