In this second post on Just in Sequence, I would like to talk about some details on the actual sequencing of parts: when to use Just in Sequence in the first place, which parts to sequence, and how to define the sequence. These are all organizational details to make Just in Sequence work. In my next and last post of this series, I will describe how to handle problems with parts being out of sequence.

In this second post on Just in Sequence, I would like to talk about some details on the actual sequencing of parts: when to use Just in Sequence in the first place, which parts to sequence, and how to define the sequence. These are all organizational details to make Just in Sequence work. In my next and last post of this series, I will describe how to handle problems with parts being out of sequence.

Prerequisites for Just in Sequence

Maintain Your Production Sequence!

For Just in Sequence to work, there are a few prerequisites. Most importantly, you need to be able to define a sequence and stick with it. Particular emphasis on “stick with it“! Pretty much all plants define a production sequence, but most plants I know won’t be able to produce tomorrow without fail what they plan today. The more “hiccups” you have in your main production sequence, the more you have to scramble around to adjust the sequences of the depending parts. If 20% of your original sequence changes even a little bit, then the resulting scrambling around may not be worth the benefits of Just in Sequence.

For Just in Sequence to work, there are a few prerequisites. Most importantly, you need to be able to define a sequence and stick with it. Particular emphasis on “stick with it“! Pretty much all plants define a production sequence, but most plants I know won’t be able to produce tomorrow without fail what they plan today. The more “hiccups” you have in your main production sequence, the more you have to scramble around to adjust the sequences of the depending parts. If 20% of your original sequence changes even a little bit, then the resulting scrambling around may not be worth the benefits of Just in Sequence.

On a side note, this in almost all cases means flow production rather than job shops. Since job shops are hell to manage anyway, you probably can forget about any sequence you would like to have at a process. For completeness’ sake, it may work again for project shops like shipbuilding of large vessels, where all material has to go to one single construction site. Yet, since shipbuilding of large vessels usually is highly customized, it may or may not be worth the effort to create a Just in Sequence supply.

Assembly Process

Just in Sequence is sequencing at least one other part to the sequence of a primary component. As such, you need at least two parts that are merged (i.e., you need an assembly process). If you are merely milling and shaping a part without attaching anything else, then you don’t need and can’t even do Just in Sequence.

Just in Sequence is sequencing at least one other part to the sequence of a primary component. As such, you need at least two parts that are merged (i.e., you need an assembly process). If you are merely milling and shaping a part without attaching anything else, then you don’t need and can’t even do Just in Sequence.

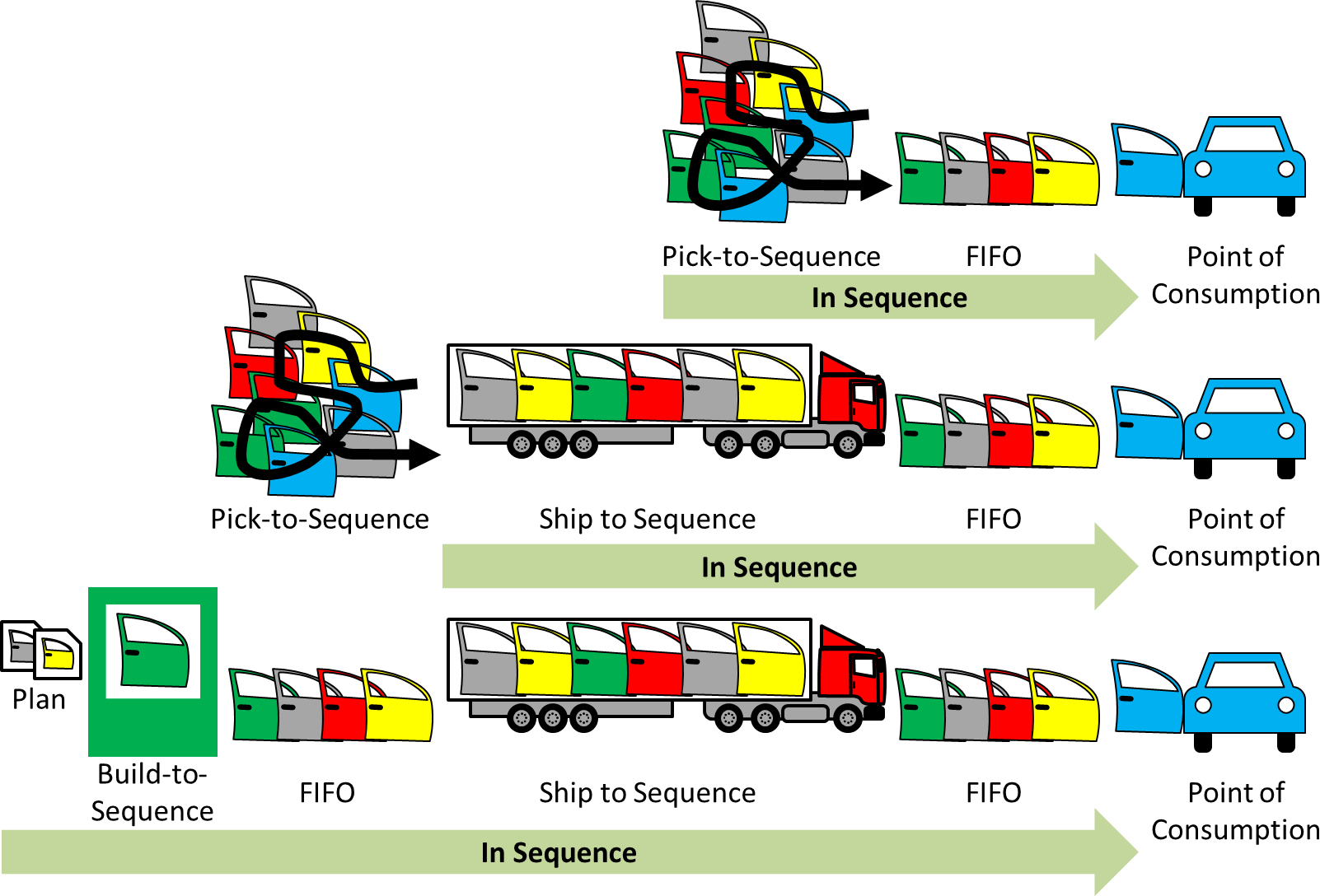

Already Have a Lean Supply Chain

If you build your sequence very close to the main line (point of consumption), then your main sequence needs to be stable only for a short time. This would be the first example in the image below. The farther away you get, the longer you need to keep your sequence stable. This is directly related to the number of parts in the sequence. The more parts you have “in sequence” between the creation of the sequence and the consumption, the longer ahead you need to fix your sequence.

For example, if you pick directly at the line, and do so around 30 minutes before the part is consumed, then your sequence needs to be unchanged for only 30 minutes. If, however, you produce in sequence a 4-hour drive away and need to plan this 6 hours before the parts are consumed, then your line needs to be stable for six hours. Don’t forget that the production needs some time to prepare and schedule too!

If you are in a typical plant with 2 weeks’ worth of inbound inventory, try to get your suppliers to not produce just in sequence, since you will never be able to hold the sequence for 2 weeks anyway! Hence, Just in Sequence benefits strongly from a lean supply chain, and therefore it benefits enormously from Just in Time and Ship to Line. If your supply line is clogged with weeks’ worth of inventory, create sequences only very close to the point of consumption (e.g., pick to sequence or build to sequence if machines are nearby). In sum, the longer the lead time from the sequence generation to the point of consumption, the longer you need to maintain sequence and the more difficult it will be.

Small Lot Sizes

Strictly speaking, this is not a prerequisite but a factor that makes Just in Sequence worthwhile or not. If you have large lot sizes (e.g., building 400 red cars in sequence), of course you could prepare 400 red doors in sequence from the supplier. You would reduce handling and organizational effort in the value stream.

However, these doors are now organized and searched not individually but in batches of 500. Hence, instead of searching a door 500 times, you search 500 doors once. You still get a small benefit (of not searching 500 doors once), but it may or may not be worth the effort of Just in Sequence.

Low Defect and Rework Rates

For Just in Sequence to work, you would need to have low defect rates for the sequenced products and the main product. The more parts you need to rework, the more parts you may have to take out of the line or sequence, which will mess up your sequence. In fact, reworks of car bodies are one of the main reasons for sequencing problems in automotive.

For Just in Sequence to work, you would need to have low defect rates for the sequenced products and the main product. The more parts you need to rework, the more parts you may have to take out of the line or sequence, which will mess up your sequence. In fact, reworks of car bodies are one of the main reasons for sequencing problems in automotive.

What Parts to Sequence?

Your product is probably made from hundreds, if not thousands of parts. Theoretically, you could sequence them all. Practically, this will be a nightmare! If only one part of your hundreds of parts is out of order, your complete sequence for all other parts is shot to shreds. The much, MUCH better way is to sequence only a few parts. But which ones?

Sequencing is good for parts that are unique or nearly so. Any component that has a large number of variants could be a candidate for sequencing. Examples in automotive industry often include car doors (splitting off from the car after painting and maintaining sequence until reassembly, door components, and seats [often external suppliers], and wire harnesses [a surprisingly complex product for “just being a bunch of cables”]).

Sequencing is good for parts that are unique or nearly so. Any component that has a large number of variants could be a candidate for sequencing. Examples in automotive industry often include car doors (splitting off from the car after painting and maintaining sequence until reassembly, door components, and seats [often external suppliers], and wire harnesses [a surprisingly complex product for “just being a bunch of cables”]).

Vice versa, if you have parts that you use in large quantities, they benefit little from sequencing. Often, in this case the effort of Just in Sequence is not worth the benefit.

Just in Sequence can reduce the effort to find the matching part. This suggests high-variety parts. Additionally, this also suggests larger parts. Finding the matching seat out of a inventory of 20 seats takes longer than finding the matching plug out of 20 electric plugs.

Hence, while Just in Sequence is theoretically possible for all parts, you should start with the large, high-variety parts. Prioritize these based on the potential benefits and pick the part that benefits most from sequencing. Once you have successfully established just in sequence for one part, you can move to the next part (and we are talking not days but rather weeks and months until your sequence is stable and you can go to the next part).

The more parts you have sequenced, the more trouble you will have in correcting mistakes (see my next post). Hence, at one point the benefit of providing more parts just in sequence will no longer be worth the effort to sequence many different part groups due to the increasing effort to correct sequencing if things go wrong. That is, until you reduce such events of mis-sequence even more than before.

What Defines the Sequence?

Just in Sequence always needs at least two components whose sequences match. You could, for example, coordinate the sequences of the trunk of the car and the body of the car (I would have used the door example again, but most cars have at least two doors, and here I would like to explain the minimum).

Just in Sequence always needs at least two components whose sequences match. You could, for example, coordinate the sequences of the trunk of the car and the body of the car (I would have used the door example again, but most cars have at least two doors, and here I would like to explain the minimum).

Now you have two options: Do you initially plan the sequence of the trunks and arrange the sequence of the bodies to match, or do you initially plan the sequence of the bodies and then arrange the sequence of the trunks to match? In this case it is easy. Since the car body is the larger component, it is more difficult to switch around and match its sequence to the trunk. Instead, most companies choose to initially plan the sequence of the car body, and then match the sequence of selected other products to the car body.

In fact, in most cases where you could use Just in Sequence, there is a main product that naturally defines the sequence, and then other smaller components that match the sequence of the main product.The sequence of the main product needs to be known beforehand. This main sequence can be defined any way you like (i.e., by customer priority, or to optimize changeovers, or to balance out the workload, etc.).

Nevertheless, for the off chance that your product does not have a main component, ask yourself what part defines the sequence and what other parts follow the sequence. In most cases the answer should be easy, but don’t skip this question.

I hope this details on how to create Just in Sequence was helpful. In my last post I will discuss how to deal with problems in the sequence. Until then, stay tuned, go out, and organize your industry!

If you know well the basic underlying lean principles you don’t have to struggle with it to understand to implement it.

As a CEO with whom all lean initiatives must begin, he needs only to articulate it in the simplest of words and terms what needs to be done in one simple sentence to his team and that is

“Go to your shop floor where all the value addition is done and achieve a state of uninterrupted value addition”

And after achieving it

“Speedup the rate of value addition in an endless manner through a step by step improvement process”

That’s all a CEO needs to do. The team while figuring out how to get to an uninterrupted value addition state will on its own identify and get rid of all the “wastes” in the system without having to study lean or getting trained in any institution to get a certification for it.

The team without having to formally get lectured to will quickly learn all the wastes that interrupt and impede value addition – All the “Lean tools” that are made so hard to learn by half baked Lean “experts” trying hard to break the skulls to put lean into them.