Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

The Typical Phases of a Lean Transformation

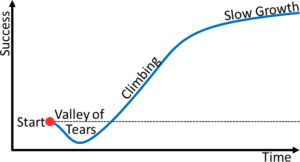

A lean transformation is a long-term strategic orientation of a company. It is more than just a lean project. In my experience, such a lean transformation goes through multiple stages. After the start, the company goes through the famous valley of tears before the performance starts to improve, first rapidly and eventually slowly.

A lean transformation is a long-term strategic orientation of a company. It is more than just a lean project. In my experience, such a lean transformation goes through multiple stages. After the start, the company goes through the famous valley of tears before the performance starts to improve, first rapidly and eventually slowly.

The Valley of Tears

At the beginning of a lean project, there is usually (but not always) the valley of tears. If you try to lose weight, your body may feel uncomfortable with the exercise, and the weight loss is probably much slower than hoped for.

Lean manufacturing is similar. By changing the system, you may upset long-established traditions and customs. Some people may fight against the change, visibly or hidden. Others may have trouble adjusting.

Most often, however, the reason for the difficulty is that the new system may still have some kinks and bugs in it. These need to be sorted out (hint: This is the C&A of the PDCA!). If you do not sort out the many little details, you may be stuck with a system that is worse than before.

Also, for your transformation, you need manpower, definitely your own, and sometimes also additional (and more expensive) hired consultants. Your people will have less time for other things during the transformation, and you may have to spend initial money with a rather fuzzy outlook about when (and if) you will get the expected benefit (which is one of the reasons accountants often have problems with lean).

Furthermore, the learning curve cannot be underestimated. There is no way a lean project is guaranteed to work. In fact, in my experience, only 50% or less of the projects actually have a benefit (albeit the reporting to upper management often makes it look better than it is). Yet, without trying you will never improve. Overall, at the beginning there may be more mistakes than later on during the transformation.

In any case, the new system may not (yet) run as smoothly as intended, and actual performance may be worse than at the beginning. The duration of the valley of tears may be from a few months to years, depending on the details of the project. Of course, done wrongly you may never come out of the valley at all. But, more on this below.

Climbing: Rapid Improvement

If you do it right, you will eventually leave the valley of tears. If you keep up the effort, then you can expect rapid improvements. Your changes start to become effective. Done correctly, they may have a domino effect throughout your value chain.

If you do it right, you will eventually leave the valley of tears. If you keep up the effort, then you can expect rapid improvements. Your changes start to become effective. Done correctly, they may have a domino effect throughout your value chain.

In the Western world, lean is often seen as a reduction of waste (muda). In my view, however, the reduction of unevenness (Mura) is even more important! Reducing waste will usually only affect the spots where the waste is reduced. Reducing unevenness is tougher, but this will often have beneficial effects throughout the value stream. In any case, done correctly you can expect to improve rapidly.

As for the time scale, it depends on how far you are away from the top. Here, we are easily talking years.

Slow Growth: World Class Performance

Eventually, your improvements will start to slow down. While you still put in a lot of effort, your resulting performance is growing slower than before. Congratulations, you are now probably among the best companies in your industry! Further improvement is still possible, but it will become more difficult to improve.

For example, it is doable to go from 60% of the deliveries on time to 85% on time. It is more difficult to go from 85% to 95%. Getting from 95% to 98% will be even more difficult, as is 98% to 99%. The closer you get to 100%, the more effort is needed to improve further. Hence, your overall performance can still increase, but it will become harder and harder to improve. At one point it will take all your effort just to maintain the current situation.

No matter whether you exercise your body or transform your company, you are in peak performance. However, both in lean transformation and in personal exercise, if you stop, your performance will suffer. It takes a continuous effort to stay on the top.

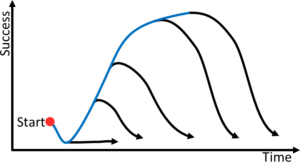

The Way Back Down

Like fitness, lean is a constant effort. The moment you stop, you will slide back down. The environment in industry is constantly changing. New products are introduced, old ones run out, suppliers and customers may change, laws may change too. Technology will both generate newer and better products as well as better and faster machines and tools. Just standing still will mean that you will fall behind.

Like fitness, lean is a constant effort. The moment you stop, you will slide back down. The environment in industry is constantly changing. New products are introduced, old ones run out, suppliers and customers may change, laws may change too. Technology will both generate newer and better products as well as better and faster machines and tools. Just standing still will mean that you will fall behind.

Kaiaku, the Opposite of Kaizen

Even worse, depending on your situation, you may end up with worse performance than before. In Japanese, there is even a word for that: Kaiaku (改悪, changing for the worse). This is for situations where an ill-fated attempt at improvement results in a system that is worse than before. It is the opposite of Kaizen (改善, continuous improvement).

In my experience, this is not uncommon. A lean transformation often consists of multiple individual lean projects. These lean projects introduce changes. At least initially, not everything may work out as planned. This is where the C&A from the PDCA comes in. Check what is not (yet) working, and keep on improving it. In my experience, this debugging often takes more time than the initial implementation.

Unfortunately, in many Western companies, a nice presentation about improvements is all management ever wants, and the problems created on the shop floor are often ignored. I have seen way too many examples of this. From new ERP software that created chaos, to Industry 4.0 solutions that looked nice on paper but did not work, to make-believe kanban cards that were just another hassle for the shop floor with no positive effect. And, don’t even get me started on leveling!

The Low-Hanging Fruits

Consultants often talk about low-hanging fruits (i.e., quick and easy projects with a high return on your effort). Yes, they do exist. Often, there are situations where you can find easy projects that quickly generate quite a bit of return.

In my experience, these are often associated with inventory reductions. In many plants I had good success with SMED (i.e., improving tool changeover speeds), which allowed us to reduce the lot sizes or produce more. At one plant I was able to give an extra month of production every year through a simple SMED. Overall, such win-win situations do exist.

Yet, in my experience, they cannot be taken for granted. Additionally, they are hard to repeat. You can “SMED” your way through your value stream only so often before further improvements become difficult.

However, many transformations do have a valley of tears. While every transformation is different, it is sometimes but not always possible to avoid this initial dip.

However, many transformations do have a valley of tears. While every transformation is different, it is sometimes but not always possible to avoid this initial dip.

In any case, I hope your transformation will be successful, and that you reach peak performance with or without a valley of tears. Now, go out, climb that curve, do not slice back again, and organize your industry!

PS: My post inspired Juan Carlos Viela to write two posts (in Spanish) that include interesting data on the valley of tears: Medir es importante I/II and Echar a andar. Las curvas del cambio II/II. In case you don’t speak Spanish, you can try Google Translate for Part 1 and Part 2.

Mr. Prof. Dr. Cristoph Roser

Your article is great and I would like to ask you if you could in future explore this topic.

When it comes to small businesses, it is very difficult to hire a consultant.

But considering that in these companies sometimes there is one or more people who have some expertise on the Lean theme how can they initiate a transformation.

Thank you so much

António

Hi Christoph: Excellent article Thanks. Just confirmed what so many others have expressed for so many years at Goggle. Nevertheless it is easier said than done. The vast majority of Lean/Six Sigma initiatives wrongly deployed confirms that.

Bain Management and Tools 2007 Survey

https://www.shmula.com/six-sigma-lean-and-executive-satisfaction/399/

Six Sigma ‘killed’ innovation in 3M | ZDNet

https://www.cbisco.com.au/2014/02/24/top-10-reasons-lean-six-sigma-projects-fail/

Top 10 Reasons Lean Six Sigma Projects Fail

https://www.isixsigma.com/implementation/success-factors/understanding-six-sigma-deployment-failures/

https://www.processexcellencenetwork.com/lean-six-sigma-business-performance/articles/5-quality-failures-that-shook-the-world

https://www.qualitymag.com/gdpr-policy?url=https%3A%2F%2Fwww.qualitymag.com%2Farticles%2F91986-reasons-organizations-do-not-use-lean-six-sigma

https://www.destinationcrm.com/Articles/Columns-Departments/The-Tipping-Point/Six-Sigma-What-Went-Wrong-51394.aspx

Why do you think people keep missing something critical and keep doing something wrong when deploying Lean/Six Sigma Initiatives. I am interested. Thanks in advance. I look forward to learning from you

These graphs are coincident with my experiences in efficiency improvement in logistics. Thanks, Christoph for your contributions.

Can I have your permission to translate it into proper Arabic for use by Symbios consulting? The translation given by google is funny and not technical.

Hi Rania, I am generally open for translations. I have sent you my framework for translations by email. Let me know when you are online 🙂

Chris

Can you give a timeline scale estimation please? For example, start to the pit of the valley of tears, 3 years? 1 year?

Hi Lynda, this is hard to generalize, it depends a lot on your production system. It could be half a year through the valley, or a year. Some companies don’t even have a valley at all. Difficult to say in general.

Great article, Christoph.

I didn’t know that Kaiaku existed, I thought it was typo. Thanks!

Aside from Kaikaku, I experienced all three phases of transformation. In my last employment as Continuous Improvement Manager, I definitely experienced the “valley of tears” for almost a year as I had to start from scratch where nobody in the company knew or ever heard of Lean Six Sigma, not even knew a thing about basic quality improvement. I was the program leader, the trainer, the A3/DMAIC project team leader, mentor all in one at the start. And I was constrained with budget as the CI program was imposed by the customer, so there was not real intent to improve but rather more of a “show and shut up”.

I began to see the climb in our performance when the key leaders I was mentoring started implementing lean and six sigma tools by themselves. I started with creating few easy projects with them to reinforce learning the basic tools and techniques. I also wisely included the calculation of cost benefits early in the projects to tell the executive management that CI isn’t just about improving quality and efficiency, but cost as well. We got the attention of our major customer such that we were awarded the Global Supplier Excellence for Continuous Improvement only after six months of implementation. We also got the Global Supplier Excellence for Customer Service as well due to our improved response and delivery time.

A year and a half later, we were achieving 30 of the 31 KPIs. The one KPI needed 99.73% yield, but we’re just hovering between 99.5% and 99.8%.

Again, thank you for this wonderful and enlightening article.

Kaiaku, the opposite of kaizen. If you are not careful, you may start with one and end up with the other. It is one of the entries in my glossary.

Let’s just say the valley of tears will be longer than you think. Trouble is, far too many companies want to become Lean just to cut costs or as a last ditch effort to get through a business downturn.Of course there are plenty of consulting outfits that specialize in convincing CEOs that hiring the firm to teach the employees how to clean better will reduce costs by 25% in six months.

The valley of tears looks different to every company. For some it may be almost nonexistent. Others have a short valley, others a long one, and some unfortunate ones manage to get stuck in the valley forever.

HI, Christoph,

Catching up after a longtime on Lean. I am sharing my views here.

Most leaders look to lean as a magic wand for removal of waste and improved profits, business results from day one of launch without even an understanding of basics of Lean.

As you have rightly said, the underlying reasons for many wastes of various resources are fluctuations as well as uncertainties in the Supply Chain.

Toyota’s success with lean perhaps can be attributed not only to their strong faith that lean works and their several decades of struggle in mastering the concept but also to aligning the entire Supply Chain to a Single culture. (Suppliers, Logistic Service Providers, Toyota and their distribution channel). They are the OEM and have almost complete control on the decisions they take.

It is here that many Tier 1 Auto Component suppliers have a big challenge as they have to deal with several big Auto sector OEMs, each with its own philosophy and culture and even idea of what Lean is.

They have to also handle the fluctuations created by all these OEMs (competing in the same market) superimposed on them and make informed decisions on their planning.

Most of the Lean initiatives are focused inwards at Tier1 Companies and perhaps with a few of the suppliers, customers that too only confined to Inbound and outbound Logistics aspects.

Such being the case, it is not surprising to see that still not many have been able to emulate Toyota successfully even after talking about it for a decade and more.

Would like to hear from you on my views.

Hi Jay …are you the Jay I know from Bosch? If so good to hear from you. Anyway, supply chain is an important part of lean, but the core ability of Toyota in my view is to consistently push for the same goals over decades. Compared to some western management which changes the goals with every new CEO or even more often. If you change you direction all the time you will never arrive.

Cheers!

Hi Chris,

Yes, I am Jay from Bosch. How are you doing?

I agree completely with you in saying that the goals often get changed or shifted with change in leaders. And this is not only within one’s own organisation but also in the external environment- especially the Customers.

Only constancy of purpose and consistency in execution will deliver sustainable results.

I believe that Toyota is able to pursue its goals consistently because of stable leadership. Also they have ensured that all their suppliers and partners understand and follow lean practices.

Even the Transport drivers are aligned. I was recently chatting with the Truck driver outside one of the Toyota factories in Bangalore. He told me that if he did not adhere to the time window and procedures, his truck will be allowed inside but not unloaded for hours.I asked him that it must be really frustrating. But to my surprise he said “No, it is good because I adhere to their procedures and timings and my truck gets released quickly”.

In a country of diverse cultures and languages, Toyota is still able to get people to do things exactly the way they want. And that in my opinion is what you have called as “consistently push for the same goals over decades” with a single-minded purpose.

Cheers!

Hi Jay, good to hear from you. Very nice example from the truck driver! It rewards the diligent ones and punishes the sloppy ones.