On September 27, I did my first Reddit: “I am a … ask me anything.” With almost four hundred comments, I consider it a quite successful AMA.

On September 27, I did my first Reddit: “I am a … ask me anything.” With almost four hundred comments, I consider it a quite successful AMA.

I am Chris Roser, a professor for production management; a lean expert; a Toyota, Bosch, and McKinsey alumnus; and I’m interested in the past, present, and future of manufacturing. I lived and worked for multiple years in the USA, in Japan, and in Europe. I run a blog, AllAboutLean.com, and just completed my first book, “Faster, Better, Cheaper” in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond.

The full AMA can be found on Reddit. Since it is the length of over ten blog posts, I chose a few questions and answers on two selected topics.

Losing Jobs through Automation and Computers?

Question: Do you think that engineers can be replaced by automation? More specifically AI and robotics? What are some jobs that will always need human input? (Mecheng1993)

Question: Do you think that engineers can be replaced by automation? More specifically AI and robotics? What are some jobs that will always need human input? (Mecheng1993)

Answer: I am convinced that in time engineers will be replaced by computers. This may happen faster than we expect (Moore’s law of doubling approximately every two years), and will probably take us by surprise. For example, Google’s Alpha Go beating a human world champion hands-down surprised the GO community, which thought this was still decades off in the future. If you are at the beginning of your career, don’t expect your job to be around as long as you do.

Jobs for humans: In manufacturing, probably everything can be automated. What probably will happen is that we will be willing to pay extra for “made by human.” In the case of very expensive cars like a Rolls Royce or an AMG sports car, the companies have one guy building a single engine. This is not cheaper or more efficient, but is sold to the customer as “something others don’t have/can’t afford.” Instead, you get the guy’s signature engraved on the engine. Already, “handmade” is prominent in some advertising for products, even though “machine made” would probably be better and cheaper. If like for me an AMG is out of your budget, you still can go for handmade soaps, clothing, jewelry, and other items.

Question: I think it will be the individualized economy that humans retain. For example, the individualized creativity of a caricature is not replaceable by a machine or algorithm. It requires a level of perception wand creativity.

Question: I think it will be the individualized economy that humans retain. For example, the individualized creativity of a caricature is not replaceable by a machine or algorithm. It requires a level of perception wand creativity.

Another would be individualized art. The Etsy economy will survive, as everyone tries to be “unique”. Not just based on “because it’s more expensive”, but because “this one is mine, and it’s not replaceable”. (tolman8r )

Answer: Disagree. There are already computers that create art that looks like it’s human made (for example, Google AI Music or a Computer generated Rembrandt Picture). For me, our brain is a connection of nodes (neurons) with electrical signals. No reason why a computer couldn’t do something similar in a few years.

Question: Hi Chris, thanks for doing an AMA. What impact do you think mass automatization will have on manufacturing jobs worldwide? And as a follow up, do you think Universal Basic Income is a way to resolve mass unemployment brought on by mass automatization? (skip-skip-vomit )

Question: Hi Chris, thanks for doing an AMA. What impact do you think mass automatization will have on manufacturing jobs worldwide? And as a follow up, do you think Universal Basic Income is a way to resolve mass unemployment brought on by mass automatization? (skip-skip-vomit )

Answer: Mass automation will make lots of people jobless, but the products will be cheaper than ever before. It will come, and I don’t think we can prevent it.

Universal basic income is a solution, but the transition will be a problem. As I said earlier, we can put our trust in the politicians that they will manage this process well, or we can accept that we are facing an enormous social crisis within the next twenty to thirty years. For an individual, I think there are two ways out: be wealthy, or have a tenure-style job. (For me, I have tenure, so I am probably on the safer side).

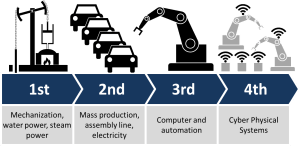

Data in Manufacturing and Industry 4.0

Question: Hi Chris, Thank you for doing AMA. I would like to ask for your opinions on industry 4.0. 1. When will it be implemented on a global scale? 2. How will it impact society and economy? would it solve the problem of poverty? (Tommynhon)

Question: Hi Chris, Thank you for doing AMA. I would like to ask for your opinions on industry 4.0. 1. When will it be implemented on a global scale? 2. How will it impact society and economy? would it solve the problem of poverty? (Tommynhon)

Answer:Oh boy … Industry 4.0. For me it is a buzzword that is already in decline. Most professionals I speak with are rather skeptical of this term. For my full opinion, check my blog post on Industry 4.0.

What you probably mean is the continuing and increasing use of computers in industry. This implementation is already ongoing. As for the impact on society, it is (and will be) HUGE! I believe that in the future we may not have to work anymore at all. The problem: Where do we get our salary from? As I said earlier in this AMA, a basic guaranteed income may be the solution, but the transition will be difficult.

In the intermediate phase, it will increase poverty. To become a modern, service-oriented society, a country must go through an industrialization phase. So far countries have industrialized by having cheaper labor, hence attracting business, hence generating wealth, until they also made the transition to a service economy (examples inclue South Korea [done] and China [in progress]). But with automation, a robot in the US/Europe will be cheaper than cheap labor in the Third World, and this gate to prosperity through manufacturing will no longer be available for poor countries.

Question:Hey Chris, Thanks for doing the AMA. This is an awesome topic, and one I’ve always been interested in. I studied applied mathematics, but I was always interested in the operations research and statistics side of things.

Question:Hey Chris, Thanks for doing the AMA. This is an awesome topic, and one I’ve always been interested in. I studied applied mathematics, but I was always interested in the operations research and statistics side of things.

What is the role of “Data Science” in manufacturing today? I know that it is primarily the tech industry which has adopted this term, but are you beginning to see the manufacturing industry also use this term? If so, what do you think are the primary differences (if any) between how a tech sector data scientist would work versus a manufacturing sector data scientist? Finally, can a company’s ability and reliance on analytics be used as a litmus test for their future?

Finally, a little more open ended: how serious do successful companies treat data versus experience? Thanks again! (EriqLaplus)

Answer: Data science, often also called Big Data: There is much potential in it. Industry collects an enormous amount of data but then does very little with it. If you have a lot of data, you can go through it and try to find correlations, maybe even causations. But this requires a lot of effort.

Currently this is missing a “killer app” in manufacturing. When you have something like this on Amazon or Facebook, the companies can analyze millions of users and generate a big benefit from it. In industry, the expense is similar but the benefit may be smaller. Also, manufacturing historically lacks the expertise for this, and does not have the right people to do it. Hence there are only few companies that are using it. Yet, as computers get smarter, they may be able to investigate data on their own without a human pulling all the strings. Then it will probably spread in industry like wildfire.

Question: I know that Amazon hires web developers to develop applications that compiles reports automatically. It isn’t even that hard to do. What do you mean that there’s no expertise? What manufacturer needs to do is first hire a dev to give them a scope of work. That is, 1. We want to be able to track XYZ, 2. We have this much money to do it, 3. Is it feasible and doable?I think there’s plenty of people who can answer those questions in the U.S., you just need the c-suite in the manufacturers to know the benefits and existence of this service. (bktechnite)

Question: I know that Amazon hires web developers to develop applications that compiles reports automatically. It isn’t even that hard to do. What do you mean that there’s no expertise? What manufacturer needs to do is first hire a dev to give them a scope of work. That is, 1. We want to be able to track XYZ, 2. We have this much money to do it, 3. Is it feasible and doable?I think there’s plenty of people who can answer those questions in the U.S., you just need the c-suite in the manufacturers to know the benefits and existence of this service. (bktechnite)

Answer: No expertise in the manufacturing firms. Also, (often) not yet the right mindset. Managers in manufacturing think in material and processes, not so much in data patterns. People use the tools they are used to and had previously good experience with. The manufacturing managers still lack this experience and may not see the need. This is slowly changing but still quite a ways away from the mad rush of companies like Google, Facebook, and Amazon competing for the best available talent (this also means that any analyst is probably expensive to hire for manufacturing companies). Also, I am not sure if a web developer is the right person to analyze big data. This is, in my opinion, more complicated than an automated report.

To use your words: “We want to be able to track XYZ” – Manufacturing managers usually don’t even know what XYZ to track.

Other Questions:

There were also some other topics discussed. Pretty much anything related to manufacturing and the future was on the table:

- Problems with ERP

- Big Data and its analysis

- Sustainable manufacturing

- Self-driving cars

- Advice for young professionals/people starting their career

- Wrong use of lean/how to “sell” lean

- How to bring back manufacturing to the US

- 3D printing

- Emerging technologies

- US presidential election

- Intercultural conflict when moving production abroad

- Industrial architecture

- Augmented reality

- Human relations at work

- Manufacturing history

Again, the full Reddit AMA is here: I am Chris Roser, a professor studying the past, present, and future of manufacturing, and just published my first book. AMA!. Overall I had quite some fun, and may do this again sometimes. In the meantime, go out and organize your industry!

Great and we are looking more from you and keep going on professor:-)

I really enjoyed it. Reddit is a quite high quality community. I will do something similar like this again in the future.