In my previous posts I went into great detail on how to prioritize your work, with a focus on made-to-stock-type production. In this last post of my series on work prioritization, I look at made-to-order systems and mixed made-to-order and made-to-stock systems.

In my previous posts I went into great detail on how to prioritize your work, with a focus on made-to-stock-type production. In this last post of my series on work prioritization, I look at made-to-order systems and mixed made-to-order and made-to-stock systems.

Made to Order Only

If you only produce made-to-order products, you may not need a VIP lane. After all, every product is custom made, and the customer wants it as fast as possible. Additionally, this priority changes frequently. Any important order may be superseded by an even more important new order. Hence, the importance changes frequently.

The best way to prioritize this in pull production is through the use of a CONWIP system. I have explained the CONWIP system in more detail before (see my series on CONWIP starting with Basics of CONWIP Systems). This time let me look only at the prioritization of the CONWIP cards.

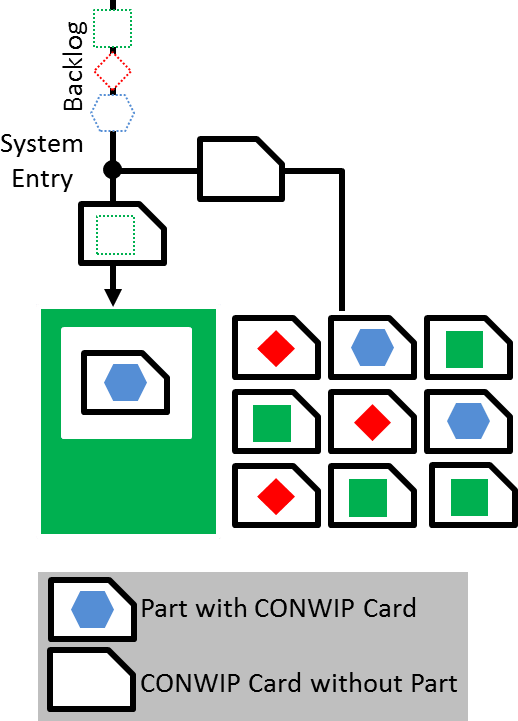

You probably have a backlog of open orders. Remember, a CONWIP card is merely the permission to start the next open order. Hence, we have a backlog of open orders, which we attach to any arriving blank CONWIP card. Whenever an order is completed, an empty CONWIP card comes back and gives permission to start the next order. The image below shows this backlog also as a queue. However, in reality it may be much more sensible to attach not the first but the most urgent card to the next arriving blank CONWIP card.

Prioritize Whenever the Next Job Can Be Started

Ideally, exactly when the next CONWIP card comes back, a manager decides which of the many open orders is the most urgent and high-priority one, attaches this order to the CONWIP card. He then hands the card over to production.

Prioritize a Small Batch

This prioritization whenever there is an opening for a new job (a blank CONWIP card) is the best prioritization approach. However, it may not be possible that a manager or supervisor is available whenever a new slot opens up. In this case, you could also prioritize a small batch of cards for the operator rather than only one card. In this case you would have a single (short) queue that contains only the next few cards that cover the time until the manager can come back and prioritize again.

This prioritization whenever there is an opening for a new job (a blank CONWIP card) is the best prioritization approach. However, it may not be possible that a manager or supervisor is available whenever a new slot opens up. In this case, you could also prioritize a small batch of cards for the operator rather than only one card. In this case you would have a single (short) queue that contains only the next few cards that cover the time until the manager can come back and prioritize again.

Mixture of Made to Order and Make to Stock

Less than 30% of the Work is CONWIP

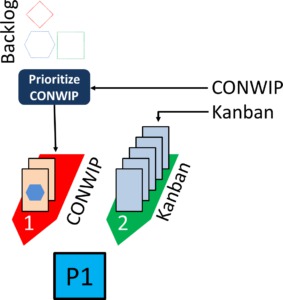

A priority system similar to the high runner and exotics can be set up if you have a mixture of made-to-order and made-to-stock production. In this case, you may have a hybrid kanban & CONWIP system. You use kanbans for made-to-stock products and CONWIP for made-to-order products. In this case your VIP lane would be your CONWIP cards, and your non-VIP lane would be your kanban cards.

A priority system similar to the high runner and exotics can be set up if you have a mixture of made-to-order and made-to-stock production. In this case, you may have a hybrid kanban & CONWIP system. You use kanbans for made-to-stock products and CONWIP for made-to-order products. In this case your VIP lane would be your CONWIP cards, and your non-VIP lane would be your kanban cards.

Of course, you would need more inventory with the kanban cards, but the lead time for the CONWIP cards would be reduced. How much faster depends on what percentage of your work is made to order. If you have 80% made to order, there will be little change. However, if you have only 20% made to order, the made-to-order products will be delivered much faster. Hence, this may only be worthwhile if your made-to-order products are only a small part of your total production, and you can accept a slightly higher made-to-stock inventory in exchange for a much faster lead time of your made-to-order products.

This can also be implemented as part of the regular standard. If set up correctly, this type of system needs no management intervention. However, especially with the CONWIP-type pull system, it is common and useful to also prioritize the open order backlog.

More than 30% of the Work is CONWIP

It becomes more tricky if you have more than 30% of your work in the form of CONWIP or made-to-order cards. In this case there is a risk of kanban cards having to wait for a long time, which also fluctuates heavily. You would need quite some inventory in your kanban (i.e., more kanban cards) to cover this. The higher your CONWIP workload compared to the kanban workload, the higher your kanban inventory would have to be, with little benefit for the CONWIP. This may not make economic sense.

It becomes more tricky if you have more than 30% of your work in the form of CONWIP or made-to-order cards. In this case there is a risk of kanban cards having to wait for a long time, which also fluctuates heavily. You would need quite some inventory in your kanban (i.e., more kanban cards) to cover this. The higher your CONWIP workload compared to the kanban workload, the higher your kanban inventory would have to be, with little benefit for the CONWIP. This may not make economic sense.

Hence, in this case it may be better to treat CONWIP and kanban with equal importance, and merely process them on a first-come first-served basis. You would still prioritize your CONWIP cards similar as for a made-to-order-only system. Every new CONWIP card gets the highest-priority job. However, after the job is attached to the CONWIP card, the CONWIP card goes to the back of the mixed CONWIP/kanban queue. In effect, you would have no prioritization.

If you still think you need some prioritization, you can do that too. In this case, however, you would need a two-stage process, where you first prioritize the open orders as described above. Only as a next step would you put selected orders in the VIP lane.

If you still think you need some prioritization, you can do that too. In this case, however, you would need a two-stage process, where you first prioritize the open orders as described above. Only as a next step would you put selected orders in the VIP lane.

These can be both kanban and CONWIP, as long as there is not too many of them. It should be no more than 10%-20% of the workload going through the VIP lane. Please note, this does not mean than the priority lane can be 20% of the length of the non-priority lane, but that 80% of total number of cards entering or leaving the queues should be non-priority. As you can see, it gets tricky. Do this only if you really, really need it.

Yet again I set out to write a short 1000-word post on prioritization, and here we are, 4000 words later, and I still have ideas for more. But, I think I have covered the most important aspects of prioritization, both for made to stock, made to order, and mixed systems. I hope this covers most situations that you may encounter in industry. So, now go out, get your priorities straight, and organize your industry!