Just in Time (JIT) is the delivery of parts just when you need them. In my last post I explained what JIT is all about. In this post (and the next one) I will go into much more detail on different measures you can take toward JIT. But be warned, most of them are not easy, either in implementing or in convincing cost accounting about it beforehand.

What Do I Need for Just in Time?

How do you get JIT? The English Wikipedia has (at the time of writing) a JIT list that looks like just about anything related to lean. While all benefit somehow, I would like to go into more detail.

Unfortunately, achieving JIT is the difficult part. You see, inventory serves a purpose. One of the main reasons we have inventory is to decouple fluctuations. If you just reduce inventory without reducing the fluctuations, you will actually increase inventory, since more material is waiting for a few missing parts.

Hence, for JIT you have to reduce fluctuations. For JIT in particular, there are a couple of measures that you can take (although all of them are quite a bit of work).

Smaller But More Frequent Deliveries

One of the easier ways to approach JIT is to make smaller but more frequent deliveries. Instead of one truck per week, can you do one truck per day (or less).

One of the easier ways to approach JIT is to make smaller but more frequent deliveries. Instead of one truck per week, can you do one truck per day (or less).

You can probably already hear the outcry from cost accounting about the additional expenses. Yes, more deliveries may cost a bit more. However, the benefit of reduced inventory is usually worth it. The problem with cost accounting is that you can calculate the expenses very easily, but it is hard to put a number on the benefits.

Hence, you could use smaller trucks and have them arrive more often instead. Of course, this cannot be sized down indefinitely. If you deliver every part separately with a scooter, then it probably will no longer be worth the benefit. In fact, even at Toyota I see most parts arriving in a mid-sized truck.

Please note that there is no point to have deliveries smaller than your lot size in production. Hence, JIT benefits also from small lot sizes and one piece flow in production.

Supply Milk Runs

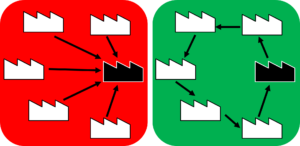

The next option to reduce your delivery size and increase you frequency (besides Pizza scooters 😉 ) is a change in the delivery structure. Instead of a hub and spoke system where a truck originates at every supplier, you could have a milk run (i.e., a truck that visits multiple suppliers in sequence and picks up their parts).

The next option to reduce your delivery size and increase you frequency (besides Pizza scooters 😉 ) is a change in the delivery structure. Instead of a hub and spoke system where a truck originates at every supplier, you could have a milk run (i.e., a truck that visits multiple suppliers in sequence and picks up their parts).

Of course, this works only if the suppliers are close to each other. After all, the travel time increases. If you increase the travel time too much, then the quantity of material on the road due to the long trip will be more than what you saved through smaller deliveries.

Here again, Little’s law is true. If you double the trip duration, you automatically double the material on the road. In this case you would need to at least half the delivery quantity for each part in order not to make it worse. However, if you can half your delivery quantity with only a slightly longer tip duration, then it will be worth it. All of this depends on how close the suppliers are to each other.

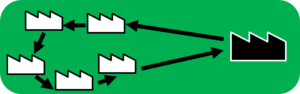

Use Clusters of Suppliers

The additional time needed for a supply milk run depends not so much on how far away the suppliers are from you (although this is relevant for another aspect as detailed in the next section). The additional time depends more on how close a group of your suppliers are together, or at least if there are some suppliers along the route to other suppliers.

The additional time needed for a supply milk run depends not so much on how far away the suppliers are from you (although this is relevant for another aspect as detailed in the next section). The additional time depends more on how close a group of your suppliers are together, or at least if there are some suppliers along the route to other suppliers.

Hence, try to find groups of suppliers so you can visit multiple suppliers on a single route without incurring too much additional trip duration.

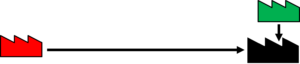

Use Local Suppliers for Fast Reactions

While it is good to have clusters of suppliers, it is even better when you are at the center of this cluster. The closer you are to your suppliers, the less material you need. Here again, Little’s law is valid. If you get your goods shipped from China, then they are en route for two to three months (including customs and all). Hence, you need two to three months of additional material that is making a tour of the world.

While it is good to have clusters of suppliers, it is even better when you are at the center of this cluster. The closer you are to your suppliers, the less material you need. Here again, Little’s law is valid. If you get your goods shipped from China, then they are en route for two to three months (including customs and all). Hence, you need two to three months of additional material that is making a tour of the world.

Being closer to your suppliers requires much less material for your supply chain. Even better, this gives you a faster reaction to changes. For example, most Japanese suppliers of Toyota are within a 100-km radius around Toyota city. For foreign plants too, Toyota tries to convince suppliers to establish a subsidiary nearby. In the case of seats, they even want to have the supplier on site, so the seats arrive just in time and just in sequence.

Another company, Inditex, better known for the clothes brand Zara, produces for the European market mostly in Europe. Despite the higher labor cost, they are successful. They have new items in stores while the competition is still loading in Shanghai. They need only one week from design to sale, whereas the competition needs around six months.

The main benefit of being close is not so much the inventory reduction, but the reaction to changes in the demand. And, while we all wish to have a constant demand, changes in the demand and subsequently in the production program and supplier orders are just a fact of life. Hence, a shorter supply chain allows a much faster reaction to the unenviable changes in production. But, the material flow is only one part of this reaction.

Work Together with Your Suppliers

Equally important is the time it takes for the information about the inevitable production changes to reach the supplier. To deliver Just in Time, the supplier has to know what you need and when. The longer the delay for the information to reach the supplier, the more difficult it will be for the supplier to deliver just in time. This, of course, means more inventory to react to unpredictable changes in what you order from the supplier. The alternative would be missing material and stopped production.

Overall, you should stay close to your supplier not only in a physical sense, but also with sharing information. Unfortunately, many companies (especially in the automotive industry) see this relation very one-sidedly. If the customer says jump, the supplier has to jump. However, when reducing fluctuations (and that’s still the big picture here), fluctuations on the supplier side are only one part of it.

Stabilize Your Production

Your supplier has to deliver the products just when you need them. For this, the supplier needs reliable information about your demand. If you decide at the last minute to change your production, then your supplier will be unable to deliver in time. Your supplier needs information about your orders some time before you need the part.

If you change your production plan when the parts are already under way, then it is too late. In fact, even when the parts are just about to be loaded may also be too late, as the supplier also needs some time to organize and structure the shipments. Hence, do not change orders on short notice, as you likely won’t get the parts in time anyway. To achieve this, you need to have a stable production with few changes. Again, this is much easier said than done.

There are many more methods to help with Just in Time. This rather lengthy list is continued in my next post. In the meantime, go out, reduce fluctuations, and organize your industry!