The previous four posts in this series for line balancing all looked at how to prepare the data and do some initial calculations. You could balance the line using a computer or – much better – do it using paper. In this fifth post, we now actually start to balance the line though shifting around small pieces of paper. In the next post I will show you some important tricks, and also how to do it on a computer (bah!).

The previous four posts in this series for line balancing all looked at how to prepare the data and do some initial calculations. You could balance the line using a computer or – much better – do it using paper. In this fifth post, we now actually start to balance the line though shifting around small pieces of paper. In the next post I will show you some important tricks, and also how to do it on a computer (bah!).

Balancing the Line on Paper

Once you have the data, balancing the line is actually not that difficult. You simply rearrange the tasks in a sequence that comes close to the target cycle time (or customer takt). I highly recommend doing it on paper, but it is also possible to do it on a computer. Let’s go through the paper version first:

Once you have the data, balancing the line is actually not that difficult. You simply rearrange the tasks in a sequence that comes close to the target cycle time (or customer takt). I highly recommend doing it on paper, but it is also possible to do it on a computer. Let’s go through the paper version first:

Preparations – Group Selection

As with many lean improvements, line balancing will be better if done in a group. Hence, rather than doing it alone in your back office, I recommend involving multiple people through one or more workshops to get the maximum out of the group intelligence.

As with most workshops, a good group size is somewhere around three to five people. If you have more, some of them will mentally disengage. If you have less, you are back to one person. If you already have some people who make these products, include at least one of them in the balancing workshop. For example, get a foreman or a respected worker who knows the products well. This way your group has a much better understanding of the sequencing and grouping flexibility.

Preparations – Stacked Bar Chart

You already have all the data you need from above. Now you need to get the data on paper. It is possible to draw it all by hand, but I usually find it difficult to get the scale right. Hence, I usually prepare a few printouts beforehand.

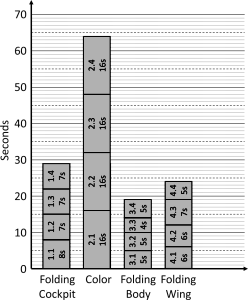

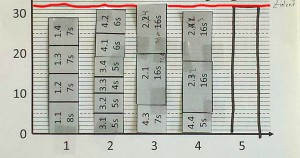

I usually create a bar chart that includes all the tasks that need to be distributed. Each stack should have the task (written out or numbered) and the time needed for this task. You can use Excel to make these stacked bar charts. If it is too tricky to add all the details in the actual bars, you can also write them on the paper by hand later.

The example shown is for my training simulation where I fold a paper plane.

You could also draw the entire bar chart by hand. This is useful if you are in the middle of a workshop and can’t take a break to prepare the chart printout. Hence, drawing it by hand does not interrupt the flow of the workshop. It is tricky, however, to get the scale right. Hence, if I somehow can get the time, I prefer to quickly add the data in Excel and print it out. This way I can ensure that all tasks have the same time scale.

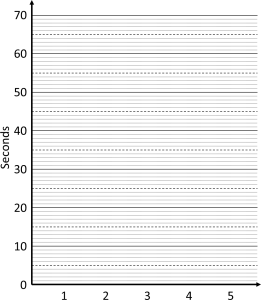

Preparations – Blank Bar Chart

It also helps to have a blank sheet to put the data on, although this is not absolutely necessary and can be drawn by hand too.

Regardless if it is drawn by hand or printed, it must have the same scale as the prepared bar chart. As for the paper size, usually I try to go for larger paper formats (e.g., A3 rather than A4 or tabloid rather than letter size). Otherwise it turns into quite a fiddling afterward.

Pro-Tip: Print out both sheets more than once, just in case you need to redo or create alternative versions.

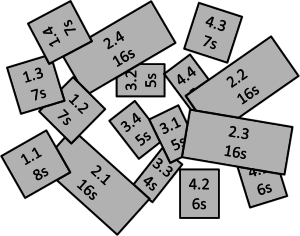

Cutting the Tasks

You now cut the tasks out of the pre-printed bar chart with the list of tasks. This gives you a piece of paper for each task that you now can distribute for balancing.

It would be also possible to use, for example, Post-its and cut them to size. This has the advantage that you can stick them to a wall. The disadvantage is the difficulty in getting the scale right. I usually go for the printed version and arrange them on a flat table, but if you prefer Post-its, they are also usable and interactive. Either way works for me.

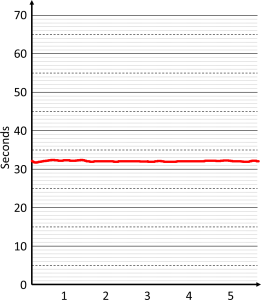

Adding the Target

Next, you add the target times to the blank chart. Usually this is the target cycle time, and usually it is the same for all processes. You could also print it out, although often I only have a black and white printer accessible but like to make the line in red. Additionally, if you do this in a workshop setting (recommended), it marks a mental milestone if you do it as part of the group activities.

If earlier you decided to go with different OEEs or to distinguish by product type, it gets a bit messier here. Hence, I again try to keep it simple.

Balancing the Line

Now comes the actual balancing of the line. You arrange the tasks in a way that they stack up to approximately your target. Always keep an eye out to see if the sequence and grouping is actually possible.

This balancing probably includes quite a few iterations. You balance the line, check if it is a doable sequence, and then adjust as needed.

By the way, if you have heard of a Yamazumi chart for line balancing, this is it! Yamazumi (山積み) literally means “to pile or heap upon.”

Once you are done, use glue or adhesive tape to attach the tasks to the paper in a more permanent way.

Summary

The above is a quick walk-through with the most important points for balancing a line by hand. However, there are still some tricks and tips that can help you. I describe these in the next post, along with the balancing of the line by computer (bah!). In the meantime, stay tuned and organize your industry!

Line Balancing Series Overview

- Data Overview: List of products, list of tasks, and customer takt

- Duration of Tasks: How to get the duration of tasks, especially if they differ among products

- OEE Caveats: Potential problems when using the OEE to transform takt times to cycle times

- OEE Usage and Flexibility: Once you have the OEE, how do you use it? Also a bit on flexibility.

- Balancing using Paper: Finally, actual line balancing using paper

- Tips and Tricks for Balancing: Some Pro-Tips, and also a bit about line balancing using computers

Hello Christoph,

I think you need to read Goldratt’s book “The Goal” and more specifically also his book “The Haystack Syndrome” a line balancing is utopia, what you need to balance is the flow through the line, not the capacity of every and each resource or station for that matter.

Best regards,

Gustavo

Hi Gustavo,

I read “the goal”, but I believe line balancing is important for a good production. The challenge are often the fluctuations around the mean, which also need t o be addressed.