Balancing the workload in a manufacturing system helps greatly in improving performance. Most importantly, it reduces unevenness (mura) due to different workloads. This in turn will reduce wasted waiting time (muda) for those with too little work, and overburden (muri) for those with too much. Additionally, I usually find it to be one of the easier aspects of lean manufacturing, since the new standard can simply be enforced through the layout of the machines. This post looks at data preparation, especially the customer takt and the list of tasks. It will be the first in a long series of posts on line balancing. The next post will look at the durations needed for the tasks.

Balancing the workload in a manufacturing system helps greatly in improving performance. Most importantly, it reduces unevenness (mura) due to different workloads. This in turn will reduce wasted waiting time (muda) for those with too little work, and overburden (muri) for those with too much. Additionally, I usually find it to be one of the easier aspects of lean manufacturing, since the new standard can simply be enforced through the layout of the machines. This post looks at data preparation, especially the customer takt and the list of tasks. It will be the first in a long series of posts on line balancing. The next post will look at the durations needed for the tasks.

Introduction

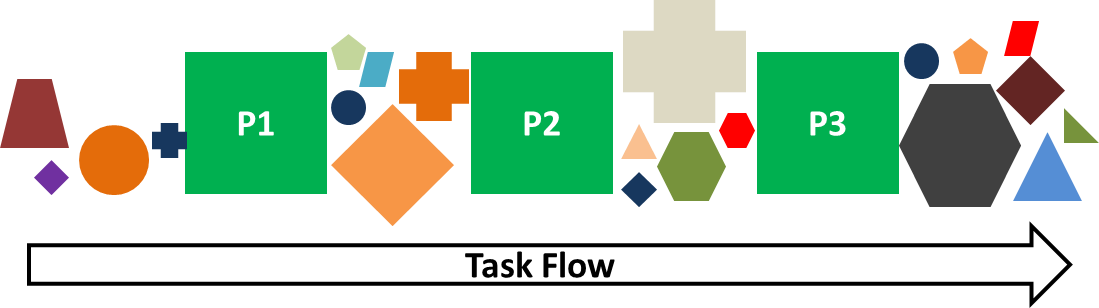

Balancing the workload among the different processes of a manufacturing system is usually straightforward. It is easiest with a flow line where all products are quite similar and go through the same sequence of processes. However, it is also possible for job shops, where the products may have a different workload and a different process sequence. However, since job shops are a bit more complicated, I will cover them in a later post.

The Product List

First, you should get an overview of all the products that will pass through your manufacturing system. This list should be as complete as possible. If all your products have the same process steps and cycle times, you may take only one major product. However, this is risky. If you miss one product with a different process step that is relevant only to this product, you end up not being able to produce this product. Best to be on the safe side and have a look at all products to be produced.

First, you should get an overview of all the products that will pass through your manufacturing system. This list should be as complete as possible. If all your products have the same process steps and cycle times, you may take only one major product. However, this is risky. If you miss one product with a different process step that is relevant only to this product, you end up not being able to produce this product. Best to be on the safe side and have a look at all products to be produced.

Meet the Customer Takt

A manufacturing system has to meet its customer takt (i.e., the average output of the system has to be at least equal to the average demand by the customer). Too little, and you sell less than you could. Too much, and you waste capacity or build up stock. For more details, see my posts How to Determine Takt Times and Pitfalls of Takt Times.

The customer takt is measured in seconds per part including all losses. Please note that I also use the term line takt or process takt for the corresponding speed of the line or process, also including all losses. Unfortunately this is not standardized, and many others also call this a cycle time, or sometimes even a process time. So, whenever I talk about a takt, I include all losses (i.e., the gross time). Whenever I talk about a cycle time, I exclude all losses (i.e., the net time). For more on this, see On the Different Ways to Measure Production Speed.

For later calculations, we need the expected customer takt for each product, or alternatively the expected quantity during a time period. It also helps to have the overall customer takt for all products combined, or alternatively the total quantity of products during a future time period. Please be aware that you cannot simply take the sum of the individual takts; you need to take the inverse of the sum of the inverse.

\[ {TT_{All}=\frac{1}{\frac{1}{TT_1}+\frac{1}{TT_2}+\frac{1}{TT_3}+…}}\]This also assumes that all parts of the production system are working at the same time and are off-shift at the same time. If you design a production system where some processes work longer (or shorter) than others, then naturally you would need a separate customer takt depending on how long they work. Luckily, if you design a line, it is rare that they have different working times.

What Do You Have to Do?

Now that you have the target customer takt, you have to figure out what you actually need to do. How much work do you have to put into your product? You need an overview of the workload, its flexibility, and the net working time for each step in the value chain.

The List of Tasks

You need to get a list of the steps you need to do in your manufacturing system. What are the value-adding actions of your system from the incoming material to the departing products? The steps should be made reasonably detailed. Anything that could be broken into stand-alone sub-steps should be broken into these sub-steps. Anything that cannot reasonably be a separate task should be grouped together.

You need to get a list of the steps you need to do in your manufacturing system. What are the value-adding actions of your system from the incoming material to the departing products? The steps should be made reasonably detailed. Anything that could be broken into stand-alone sub-steps should be broken into these sub-steps. Anything that cannot reasonably be a separate task should be grouped together.

For example, if you drill three holes of different diameter, it makes sense to have three tasks, one for each hole. However, while you need to pick up the drill, attach the drill bit, and drill the hole, you should not separate these into individual tasks, as they usually have to be together.

Admittedly, this is difficult to explain in theory. However, if you have a real manufacturing system, this usually comes across easily. Even if you later change your mind, it is always possible to merge tasks again. It is also possible to split one task into two, although this requires a new estimation of the cycle time of the separate tasks. In any case, splitting the work based on the smallest stand-alone tasks will help you later when rearranging the steps.

Usually, I add these tasks into an excel file. As you balance the line, more and more data will be added to this excel file. This will be helpful later on when you balance the line.

Task Variations Due to Product Variations

The list of tasks is easiest if you have a flow line with very similar products that require identical product steps. In this case you merely need to take one sample product, ideally the one with the highest quantity, and create the task list. Since all products have the same tasks, this list will represent all products.

The list of tasks is easiest if you have a flow line with very similar products that require identical product steps. In this case you merely need to take one sample product, ideally the one with the highest quantity, and create the task list. Since all products have the same tasks, this list will represent all products.

It becomes more tricky if some products have different tasks. For example, some products may require additional process steps, whereas others may require fewer. The list of tasks must contain all steps that are required for all the products in the production system! If you leave one step out, you may end up missing the task in the final system and hence will be unable to produce. That is the reason I recommended looking at all products going through the system, lest you miss one task for an rarely produced but still needed exotic product.

Summary

Getting an overview of the products, tasks, and the customer takt is the first step in line balancing. Yet, this just gets us started. In the next post of our multi-post series, we look at the times needed to do the different tasks. If all parts have the same tasks and durations, this is easy. However, if they differ you may need to pull some tricks. So stay tuned, and in the meantime go out and organize your industry!

Line Balancing Series Overview

- Data Overview: List of products, list of tasks, and customer takt

- Duration of Tasks: How to get the duration of tasks, especially if they differ among products

- OEE Caveats: Potential problems when using the OEE to transform takt times to cycle times

- OEE Usage and Flexibility: Once you have the OEE, how do you use it? Also a bit on flexibility.

- Balancing using Paper: Finally, actual line balancing using paper

- Tips and Tricks for Balancing: Some Pro-Tips, and also a bit about line balancing using computers