Lean started with manufacturing, but since then has moved in many other areas of the economy, from lean banking to lean healthcare. One major part of modern economy is administrative processes, which includes things like making offers, procurement, accounting, engineering, research, and many others. By some estimates, more than half of the cost of producing companies are in administration. Up to 80 percent of the lead time is due to administration. A lot of the principles behind lean can be used in administration. However, there are also some unique challenges that are less prominent in manufacturing. Let’s have a look.

Lean started with manufacturing, but since then has moved in many other areas of the economy, from lean banking to lean healthcare. One major part of modern economy is administrative processes, which includes things like making offers, procurement, accounting, engineering, research, and many others. By some estimates, more than half of the cost of producing companies are in administration. Up to 80 percent of the lead time is due to administration. A lot of the principles behind lean can be used in administration. However, there are also some unique challenges that are less prominent in manufacturing. Let’s have a look.

Lean Principles Still Apply

The underlying ideas of lean are still good for administration. Below is a selection of these ideas. But please note that I myself do not yet have a good enough grasp of lean in my head to postulate a comprehensive list of lean principles. Shockingly, I don’t know everything about lean. Even more shockingly, I admit it. The ideas below are just examples of what helps with lean, and they are neither complete nor without overlap.

The underlying ideas of lean are still good for administration. Below is a selection of these ideas. But please note that I myself do not yet have a good enough grasp of lean in my head to postulate a comprehensive list of lean principles. Shockingly, I don’t know everything about lean. Even more shockingly, I admit it. The ideas below are just examples of what helps with lean, and they are neither complete nor without overlap.

- Eliminate of Muda, Mura, and Muri (waste, unevenness, overburden)

- Improve quality

- Be nice to people, including those you don’t have to be (e.g., your own, your suppliers)

- Don’t trust KPI, but go see the people actually working and talk with them

- Try to make a pull system by limiting the WIP

- Division of Labor

- Use visual management

- Pay attention to details

I’m also aware that the points above are rather general. Telling someone to reduce unevenness tells you little about how to do it, and talking is also much easier than doing.

The Challenges of Lean Administration

While most ideas and tools in lean can also be used for administrative processes, there are some challenges that are more problematic in administration than in manufacturing.

The work content is much less standardized

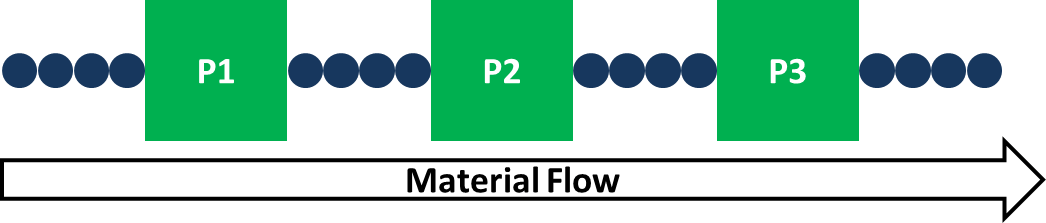

In manufacturing, particularly in flow production, you can expect every part coming down the line to be all but identical to the previous part. Even with different part variants, they have much in common.

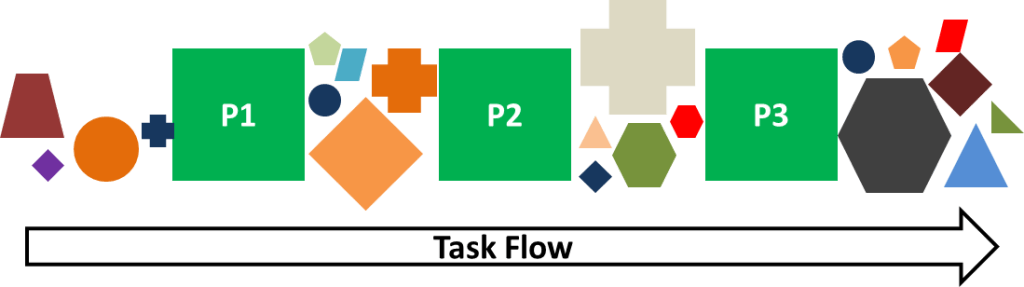

This is often not so in administration. For example, if your administrative process prepares offers to customers, one offer may be quick and easy, but the next one may be more difficult than ten easy ones. Or take a call center. One customer is happy after 30 seconds of conversation, whereas another customer takes ten minutes and then still wants to talk to the manager. Overall, in administration you never know how much work the next task will be until you actually look at it. In short, you cannot judge the amount of work by the height of the stack of folders.

The flow of the work is less standardized

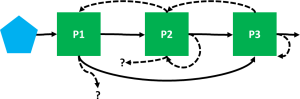

In manufacturing, if you have a flow shop, all parts follow the same sequence. Even for a job shop, the sequence of the parts is usually well defined even though it may be different for each part. Loops are rare. Once a part goes through a certain process, it is unlikely that this part will be sent back to be processed again.

In administration, however, this sequence is usually much less defined. Depending on the task, the sequence of steps may not even be known beforehand. For example, take the process of making an offer to the customer. Depending on the details of the offer, different people may be involved. More than one person could work simultaneously on the same offer. Also, if there are problems, loops are common. The offer may be handed back to the previous process steps for clarification or correction.

It is more difficult to observe the work

For me, an important part of improving a situation is to observe and find the potentials. This often includes an estimate on the cycle times.

For me, an important part of improving a situation is to observe and find the potentials. This often includes an estimate on the cycle times.

For administration, however, this is also more difficult. Modern administration is usually done on a computer. Observing an administration office is seeing a lot of people doing something on a computer – and unless you pay close attention, you have no idea if this is actual work or Facebook.

It is more difficult to enforce work standards

When improving manufacturing, it is important that these improvements stick. An improvement is worthless if everybody turns around and falls back into the old style. Standards help with maintaining a new (and hopefully better) way of doing things. Yet even in manufacturing, there is a tendency to fall back to the old ways. In my experience, it helps if the standard is somewhat set in stone. It helps if the standard is enforced through the design of the process. It helps if the process is changed in a way that only the new way is possible, or at least sensible. For example, if you rearrange the sequence of the work by rearranging the machines, it would be highly impractical to do the old sequence with the new layout. We often don’t think about this as a way to enforce standards because it is so obvious.

In administration, unfortunately, it seems to be a bit more difficult to enforce standards through the design of the process. This is especially true if it is done by paper. To take an example outside of industry, if you check into a hotel, sometimes you are asked to fill out a registration form. To be honest, I am usually quite sloppy doing so. My address is usually without zip code. If they ask for my e-mail, I just leave this blank. If they want my passport number, I am definitely too lazy to pull out my papers and look up the number, but just write a bunch of numbers anyway. And usually it works. The front desk seems to be more interested in getting a paper than getting correct information. Hence, it is very easy to circumvent the standards.

In administration, unfortunately, it seems to be a bit more difficult to enforce standards through the design of the process. This is especially true if it is done by paper. To take an example outside of industry, if you check into a hotel, sometimes you are asked to fill out a registration form. To be honest, I am usually quite sloppy doing so. My address is usually without zip code. If they ask for my e-mail, I just leave this blank. If they want my passport number, I am definitely too lazy to pull out my papers and look up the number, but just write a bunch of numbers anyway. And usually it works. The front desk seems to be more interested in getting a paper than getting correct information. Hence, it is very easy to circumvent the standards.

This is more difficult with mechanical items. If I am too lazy to put batteries in my remote, my remote clearly tells me that this is not acceptable (by not working). Similar examples can be found all over administrative processes.

There may be a tad more standard in software programs, which often work only if something is actually filled out. For example, if registering online, it may work only if there is actually a a valid e-mail address or a phone number added. Yet how do they know if I added the right number? Besides, just because they ask does not mean I want to surrender my phone number. Same in industry. ERP programs often require an input to proceed, but have no quality control if he input is correct. Experienced administrators often know where to pay attention and where just to write something to move ahead.

On a side note, it seems to me that the higher the pay grade, the more difficult it is to make people follow a standard. Hence, when implementing a standard, better-paid white-collar workers may resist more than blue-collar workers.

Lean Administration Is Still Worth the Effort

All the above problems sound daunting. Administration often is still far behind manufacturing in terms of quality, efficiency, and standard. To me it feels like manufacturing before Henry Ford and his assembly line (i.e., very chaotic).

Yet, difficult does not mean you should not try. For Henry Ford, it was an enormous effort to create assembly lines. This effort, however, created a gargantuan benefit, making Ford the largest car maker of his time.

Similarly, there is lots of potential in administration. Since it is more difficult, it often means that fewer people have tried. Hence, there are more low-hanging fruits. It may be near impossible to achieve the efficiency, speed, and quality of a modern assembly line in administration, yet any step in that direction will improve your bottom line.

As mentioned above, most of the ideas and methods behind lean will also work in administration. Some lean tools are even designed specifically for administration (e.g., the swim lane diagrams). In any case, you should not overlook your administrative processes when you work to organize your industry!

P.S.: This post was inspired by a question from Veronique Zuber. Name mentioned with permission.

See also my Academic Writing

- Roser, Christoph. “Taiichi Ohno’s Chalk Circle in the Office.” In Proceedings of the European Lean Educators Conference. Buckingham, England, 2016.

great article…………..

Thank you, it is a good article.

Very good comparison and informative article. Keep developing and sharing Thoughts and observations.

The link leads to a real experience in the administrative field. It belongs to a human resources supplier.

https://loypro.wordpress.com/2015/06/07/se-busca-productividad/

I talks about setting standard times, and time comparison between offices working under different procedures.

It is written in spanish and needs translation.

I hope you enjoy it.