Andons are systems to alert operators and managers about current problems in manufacturing. The system automates the information flow in case of problems. An Andon system usually consists of the actual Andon, sometimes called an Andon board. Often, additional input and output devices are possible, the most famous being probably the Andon line, a cord that can be pulled to alert others about a problem. In a second post I will talk about How to Use an Andon – and How Not To.

Origin of the Term

Andon (行灯, あんどん) fixed paper-enclosed lantern; paper glued over a wooden or metal frame housing an (oil) lamp. Originally portable, later mainly with a wooden stand.The term Andon comes from Japanese paper lanterns used for lighting since the Edo period. As such, it is one of the different traditional paper-covered lanterns and lights, others being Bonbori (雪洞) or Chōchin (提灯).

The term was used by Toyota for their signal system to improve their response time. However, the idea of using signals and cords is older than Toyota. A very similar system was already used in Ford factories before 1930, as described in Ford Men and Methods by Edwin P. Norwood. Back then, any worker could stop the line by pulling a cord if the problems overwhelmed him (thanks to Mark Warren for pointing out the book to me).

The Purpose of an Andon

Accelerating Information Flow

The main purpose of Andon is to improve the flow of information in case of problems. All factories have problems that may delay or stop production (yes, even Toyota). A good factory has fewer problems, can fix them faster, and tries to eliminate the root cause of the problem. Andon can help with that process by standardizing and accelerating the information flow, and hence enabling a faster response with less effort wasted on conveying the information.

How It Should Not Be…

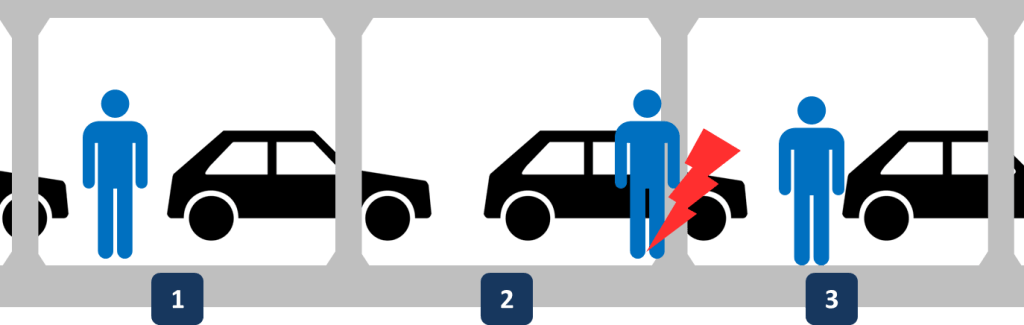

But before we go to the good factories, let’s talk first about the … normal … factories. In the West, a popular way to combat production problems is traditional firefighting: find somebody that can fix the symptoms so the work can continue. However, it will often take some time before the operator notices or escalates the problem. It will take more time to find somebody who can help. And, depending on the availability of the firefighter, it may be fixed sooner or later, usually by de-prioritizing something else. Of course, fixing here means, more often than not, fixing only the symptoms and not the cause.

Does this sound familiar? Unfortunately, this wasteful process is still far too common in manufacturing. In fact, it feels like many people justify their purpose through firefighting, and don’t even want to have a normal, smooth process. If there are no fires, then there is no need for heroes who put them out. In movies, the hero is rarely the engineer and designer who prevented the catastrophe from happening in the first place. Yet, many careers are built by being a hero…

How an Andon Works

Input for the Andon System

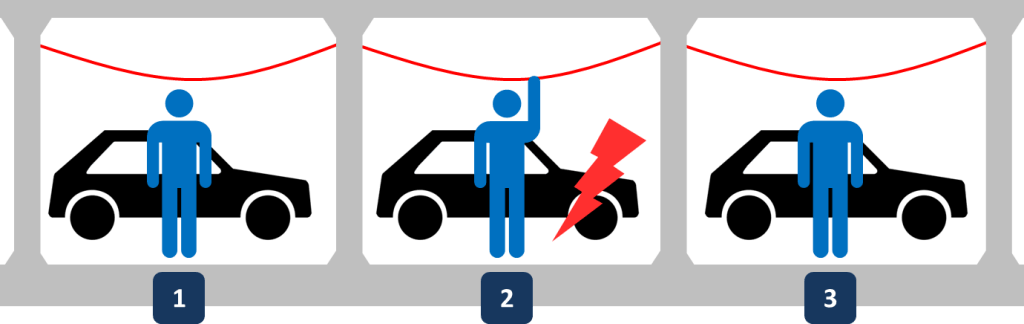

An Andon accelerates the information flow related to slowdowns and stops of the production system. As such, it has inputs and outputs. Information about problems is put into the system. This can happen manually. Most famous is probably the Andon cord, also known as the Andon line (also in Japanese) or Andon rope. This is a rope hanging from the ceiling. If the operator encounters a problem, he pulls the rope, which gives a signal to the Andon that there is a problem. Usually a second pull cancels the signal and tells the Andon that the problem is solved.

The cord is probably best known, but it does not have to be a cord. It could also be an Andon switch or an Andon button. A cord has the advantage that on a larger assembly line, it gives easy access to the signal line over a longer distance, whereas with a button the worker may have to walk over to it before pressing it. Of course, for smaller work spaces, a button or switch will be just fine since the worker is not walking around anyway.

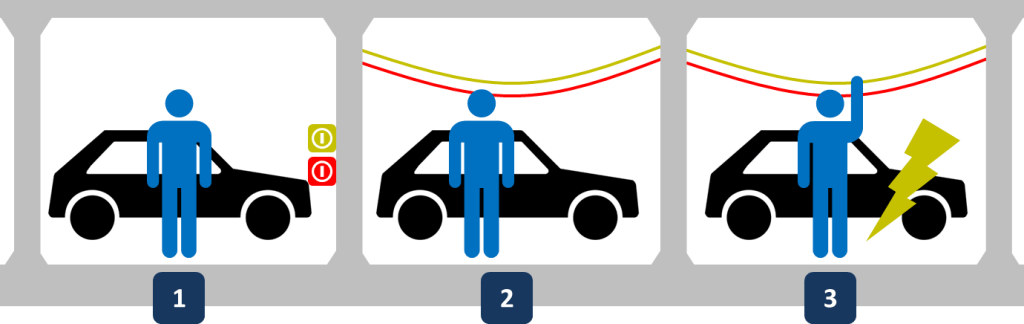

Ideally, every station at the value stream has its own button or cord. This way, the system knows not only that there has been a problem, but where the problem occurred. It is even possible to have more than one cord or button. For example, you could have a yellow cord if the operator has a problem but he is not yet sure if he can fix it in time without stopping the line. If he could not fix the problem and has to stop the line, he pulls the red cord to signal a line stop. One option for the line stop is also to keep the line moving until the product has reached the end of the individual station. Only when the “time is up” does the line stop completely. This allows calling for help while the line still moves, and hence creates less inconvenience for other stations. It also allows a faster start after the problem is fixed, since the next product will be arriving almost immediately.

However, make sure you don’t overdo it with the number of lines and the quantity of input. One line is usually a good starting point, more than three lines is excessive, and you don’t want the operator to type in a problem report while the line is waiting for him to actually fix the problem!

Of course, there could also be an automatic input into the Andon system. For an assembly line, the system could sense if all necessary operations have been completed. If there are still open tasks when the time is up, it means the worker is either falling behind or forgot something. In any case, it is a problem and a signal can be sent automatically. Similarly, for an automatic or semi-automatic machine, sensors and programmed logic can detect a current or even a potential upcoming slowdown or stop. This information is then also forwarded into the Andon system.

Additionally, many Andon systems also automatically measure things like production speed, actual and target quantities, and other parameters relevant to the performance of the line.

Output of the Andon System

The Andon system receives data on the production performance from different sources like sensors, programs, or manual inputs. This data is then displayed, usually in a visual manner involving lights, but also possibly in numbers or even audio signals or through mobile phone networks. As such, Andon can be part of visual management.

Probably the simplest Andon system is a stack light or industrial light tower on top of a machine. One or more lights indicate the current status of the machine. Even combinations are possible (green light on, yellow is blinking). Common colors are green for regular operations, red for larger problems or defects (or, alternatively, a call for assistance), orange for warnings, blue for a request for assistance, and white if all the other colors are not enough for you 😛 .

More closely associated with Andon, however, are Andon boards. These summarize the information about the status of the production system on one board. This board can be created using different lights and LED number displays. Alternatively, you can also simply use a large-screen monitor and program all the display functions into the software. While the monitor is fancier, at Toyota I usually see old-school mechanical constructs for the Andon boards.

More closely associated with Andon, however, are Andon boards. These summarize the information about the status of the production system on one board. This board can be created using different lights and LED number displays. Alternatively, you can also simply use a large-screen monitor and program all the display functions into the software. While the monitor is fancier, at Toyota I usually see old-school mechanical constructs for the Andon boards.

This board should display the relevant information from the Andon system. Usually, it shows the status of the different processes in the system, and an actual and target production value. It may show defect quantities, efficiency, or material supply issues. You can add anything that you think is useful. You can also add sound signals. At one Toyota line, I have seen different chimes used for different stations on the line. Hence, in case of problems, you don’t even have to look but already know where the problem is. As usual, both with visual and audio signals, don’t overdo it. Try to focus on the important things.

One of the advantages of an Andon system is that you are not limited to one board. I know one plant manager who installed a smaller version of the Andon board in his office. At another plant, they had an automatic escalation of production problems. After a two-hour stop, the shop floor section manager automatically received an SMS on his mobile phone; after four hours, the production manager got an SMS; and after eight hours, the plant manager automatically got an SMS, day or night. Note: Before you copy that, try to estimate how many nights of sleep you get before setting up a thirty-minute stoppage alert.

Additionally, if there is a problem that cannot be fixed within the cycle time, the Andon system can automatically stop the line or the process. For example, if the operator pulls the red Andon cord, the line stops until the problem is fixed. This is one of the outputs of an Andon system, and also one of the automatic responses that a good Andon should make in case of problems.

Additionally, if there is a problem that cannot be fixed within the cycle time, the Andon system can automatically stop the line or the process. For example, if the operator pulls the red Andon cord, the line stops until the problem is fixed. This is one of the outputs of an Andon system, and also one of the automatic responses that a good Andon should make in case of problems.

Of course, there are more responses necessary, but unfortunately most of them are not handled by an automatic system, but by a human. This is actually where most (Western) Andon systems fail. More on this in a second post about How to Use an Andon – and How Not To, so stay tuned. In the meantime, go out and organize your industry!

Hi Christoph,

Good information about Andons. If I may add a few insights from the Toyota floor….

In my experience at Toyota, the assembly lines had a fixed position stop. So when the Andon cord is pulled, the line continues to move until it gets to the end of the particular work station, (if nobody answers the Andon) then the line stops. Another aspect common on Toyota Andons is the ability to call for help w/out the line stopping. A worker may be low on parts or need to go to the restroom. In these cases, they call on the Andon and the line doesn’t stop.

All Andons should have sound. Since leaders and maintenance can’t watch the Andon constantly, the sound is the signal to look at the Andon to see where the problem is located. Leaders then go to that work station.

Additionally, Toyota Andons have different sounds to indicate who is being called. We had different tones for a Production call and a Maintenance call. If the worker needs both Production AND Maintenance, they signal for both.

One of the important advantages of Andons is the fact that leadership and Maintenance aren’t required to constantly monitor the line which allows them to do other work (like quality checks) until someone calls for assistance.

Some Andons are also tied into PLCs which measure, in seconds and minutes, cumulative downtime at each work station. This allows hourly documentation of problems and countermeasures at particular work stations throughout the shift on a Production Board and a Line Stop Report. This enables leadership to see how significant each problem is (time the line is stopped/reason) and whether it’s a repeat problem. This information is critical to the problem solving process.

Regards,

Phil

Hi Phil,

excellent information. I had the info on the different sounds in my post already, but I just added the info on the line stopping only at the end of the station. As for the response for the call for help: this will be my next post next week: How to Use an Andon – and How Not To.

But great input, many thanks for taking the time to write it.

Cheers,

Chris

Hi christoph

many times I have been observed, the moment operator pulls the rope, and team leader come to station and pulls the rope to start the line, or production before getting the information from the operator.

how to handle this kind of situations

regards

vijay

Hi Vijay,

the important part is that the line stops before the problem is moved to the next station. It may have been a line that is only used to call the team leader, without stopping the line, and the team leader just cancelled the signal after he arrived. If it was a andon line that actually stopped the line, then I am not quite sure why the team leader restarted it immediately.

thanks for information.

too interesting

Hello Christoph,

I am thinking about implementing an andon system in my construction company.

I was searching for qualitative results on the andon system in general to convince the director. However it is difficult to find data.

I was looking for something like, e.g.: 30% of productivity improvement, etc.

Do you know any article or study that has such type of data as results?

Appreciate your reply!

Thank you!

Kind regards,

Evandro

Hi Evandro, I haven’t seen such data, and even if I would be skeptical about its validity. There are too many other effects that influence the result. Sorry.

Hello. Any thoughts of using the andon system but in a customer service environment? Any electronic/virtual options for an andon system?

thanks,

-Estela

Hi Estela, the main difference would be that if the the “product” is a customer, the customer would be interested in the current situation, especially the waiting time. Such systems are already common with the “pull a number” approach. You get a number from a machine, and can see on a display when you are up, where to go, and (ideally) also how many people are in front of you. A simplified non-digital method is e.g. at Disneyland. If you queue there, you will see signs like “30 min wait from here” etc. Both quite helpful compared to the “dumb” line.