The customer takt (or takt time) is one of the fundamentals for determining the speed of a production system. It represents the available time divided by the average demand of the customer during that time. Effectively this is the average time between the order of one item. Whenever you design a new production system or change an existing system, one of the early data inputs you need is the customer takt. While the customer takt can be simply calculated by dividing the demand by the time available for production, there are many more details needed to understand it fully.

Why do we need Takt Time?

The takt time gives us a measure of the customer demand over time, of which for practical reasons the inverse is used (i.e. the time over demand). There are two main reasons why you need the customer takt:

Production Speed: If you know how fast your customer requires parts, you know how fast your processes have to run in average, or – dividing the customer takt by the OEE – how fast your processes have to be before the usual break downs and other problems slow you down. Hence, the customer takt helps you to determine how fast your processes must be.

Number of Kanban: If you use a kanban based pull system, you need to determine the number of kanban. One way is to calculate them. For this, the customer takt is an important input in the calculation.

Attention: For the same line and the same period, the customer takts may be different. For the production speed you need to calculate the customer takt across all part types. For the kanban calculation, you must calculate it separately for every part type that you need kanbans for. Do not mix these two up!

Additionally, you can not only calculate the customer takt that you need, but also the process, system or line takt that the system can deliver. Of course, the target system/line/process takt should be slightly faster than the customer takt.

Please be aware that a significant number of practitioners prefer to call the process or line takt a “cycle time”! This has significant potential for confusion! I strongly prefer to use cycle time only for times without unplanned losses or delays. In any case, if discussion takt times and cycle times with someone else, please verify what they are talking about!

How to calculate the Customer Takt

Simply said, the customer takt is the average time between the demand for a part. To calculate it, you divide the available working time by the customer demand during that time.

Simply said, the customer takt is the average time between the demand for a part. To calculate it, you divide the available working time by the customer demand during that time.

By the way, the throughput is simply the inverse of the takt time, although usually used only for the actual or target production, not the customer demand:

\[ Throughput= \frac{Parts \; Produced \; during \; available \; Work \; Time}{Available \; Work \; Time}\]However, while the formula looks (and is) simple, there are still many possibilities to put in the wrong data. Hence, we’ll look at the two variables in more detail:

The Available Work Time

The numerator in the equation above is the available work time. Hence, we should definitely exclude times that the production system in question is not running. For example, if your system works only two shifts for five days per week, do not include off shifts. We should include only these two shifts for five days per week. Additionally, we should also exclude regular breaks like lunch or breakfast.

We could additionally exclude other irregular but scheduled breaks like company meetings, although in my opinion this is blurring the line. In my opinion this effort is usually not worth the benefits. You may get a customer takt that is slightly more precise, but the difference in all likelihood will not be that large. Later, when we use the customer takt to design the line speeds, we should keep some flexibility anyway.

You should include non-scheduled breaks that are part of the regular operations of the system like breakdowns, change overs, or repairs. Overall, try to include as much of the lost time in the work time. The distinction to an efficient time is done later with the cycle time.

Later, we will use the customer takt in combination with the OEE to determine the target cycle time of the system. For the OEE, we also use a working time as part of the OEE calculation. The definition of available time you use for the customer takt must be the same as the time basis you use to calculate the OEE! For example if you exclude maintenance for the customer takt, you must also exclude it when calculating the OEE. If you include it for one but not the other, the numbers no longer match. See my posts on OEE for more details there.

The Quantity

As for the denominator of the demand, this represents the total demand by the customer during the available work time. This is usually the predicted demand for the future, which by its nature may include uncertainties. Additionally, the customer may order anytime day or night, but your manufacturing will produce it only during work times. Hence, if the customer orders 10.000 products in one month, the available work time of this month is divided by the number of products.

As for the quantity, you could either use the sum of all parts produced on the line, or you could split it by product type. Both is quite feasible. If you want to determine the speed of the machines, you must take all parts into account. On the other hand, if you want to calculate the number of kanban, you must calculate the customer takt and the subsequent number of kanban for every part type separately.

Naturally you need to keep an eye out for the difference between the demand of the end customer and the demand by the next station down the line. For example, if the customer will order 2000 cars per month, your demand on wheels would of course be 8000 wheels per month, since one car (usually) equals to four wheels.

The analyzed Period

Another relevant question is to decide which period you want to analyze. Are you interested in last week or next week? Do you want to know the next month, quarter, or the entire year?

In my experience, past customer takts are rarely calculated (unless you assume that the future will behave similarly to the past). Most practitioners are interested in future customer takts to prepare their systems for future demands. One problem is to determine the behavior of the future. Since the available work time is usually set by the plant, you have some certainty about the behavior of the work time.

On the other hand, customers are known to behave quite unpredictably. How do you know what the customer will order next week, let alone next year? I can’t help you with that problem here (this would be another post), but I can tell you a bit about what period to use. It all depends on what you want to do with the customer takt. If you merely want to update the number of kanban, then a shorter view of a few weeks or months may be sufficient.

If you have a highly flexible line where you can adjust e.g. the number of workers, you may be interested in the customer takt for next week to determine how many workers you should plan for that line.

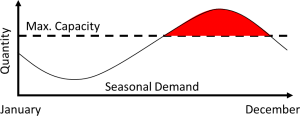

If you are building a new line or expanding an existing line, you may be interested in multiple months or even years of demand. For such long term plans the customer behavior becomes not only less certain, but it may also have seasonal behavior.

Do you want to set up the system for the average demand, or the peak demand? How much can you ramp up your capacity, how much do you want to stock beforehand, and how much are you willing to risk in missed sales? In any case, it does help to understand the peak demand of the year, e.g. the month with the highest sales, even though you may still choose a line speed below the peak demand.

Customer, Line, and Process Takt

As you can calculate the time per part for the customer demand, you can also calculate the time per part your line or process can produce. These I call line takt or process takt – although there are a lot of different and non-standardized terms out there in the field for this speed measurement.

Ideally, your line takt should be a teeny bit faster than the customer takt. If you are slower, you won’t be able to satisfy the customer demand. If you are much faster, your people or machines have not enough work. The easiest way to adjust this is through the working hours.

Summary

Overall, takt time is the available work time divided by the average number of parts needed (or produced) during that time. The above calculations are an easy case. In my next post Pitfalls of Takt Times I talk more about the pitfalls of takt times, especially for parallel processes. I will also briefly talk about history and why this Japanese technique has a German name, and will calculate an example. In the meantime understand the rhythm of your system so you can go out and Organize your Industry!

Dear Chris,

I have enjoyed your article.

There are Toyota professionals and in LEI who disagree with subtracting breakdowns, changeovers..etc. I actually agree with them as this creates mentality ‘this is our capabilities’ and take their waste as fact and bury the waste into the system.

I agree with them, too. The line takt should include all wastes (breakdown, maintenance, change over, …). The cycle time on the other hand should be as much as possible without wastes. The ratio between the two is the OEE. This way you can see both your actual ability, and your ability if you would have no waste.