The speed of your production system is a key aspect of your manufacturing system, and controlling it is important for the success of your organization. Unfortunately, there are many different and confusing ways to measure the manufacturing speed. Even a simple question on how to call a speed is often confused, with many practitioners using the same term for different measurements, or different terms for the same measurements. This post aims to give an overview of what is out there, and what it is good for.

Lots of confused Terms

There are tons of different terms used by practitioners about the speed of the line: cycle time, takt time, process time, target cycle time, effective cycle time, line takt, … and many more. Unfortunately, often different lean practitioners mean different things using the same term, or mean the same thing but use different terms. This is not good. The line speed is one of the important aspects in improving your system. Yet, exactly at this key point of lean manufacturing, the terminology about line speed is absolutely not standardized. This has potential for major confusion!

What I describe below is what I think makes most sense, but I also often point out how it also may be called by others. So please, if you have a different idea on how to call things, please let me know!

Many Questions to ask

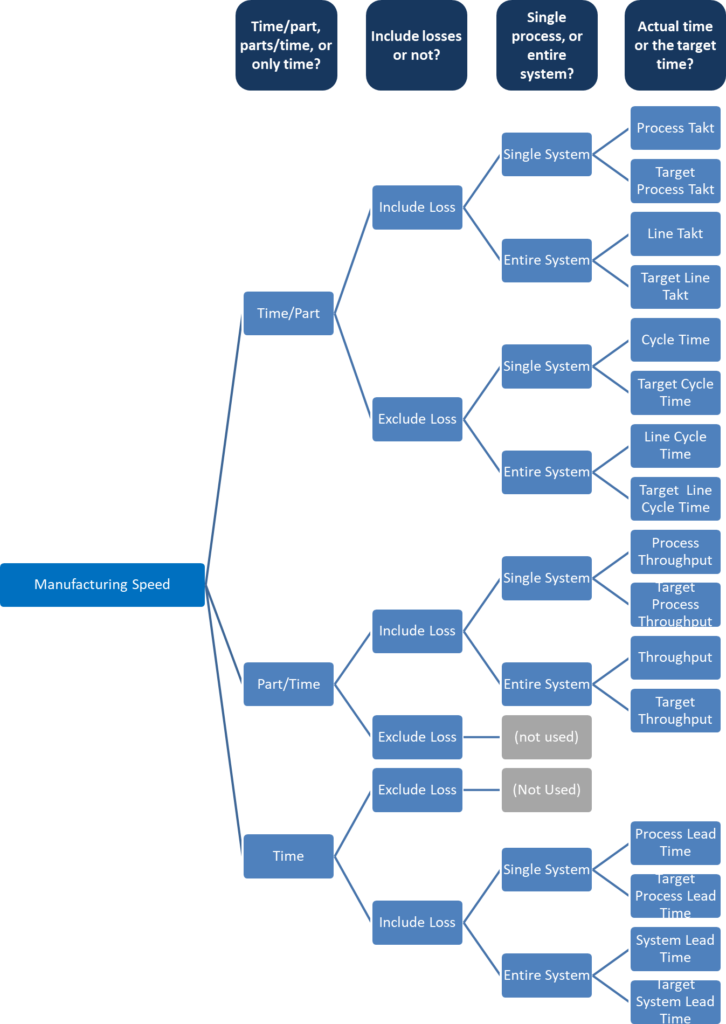

To sort out these different speed measurements there are a few key questions to help you figure out the differences:

To sort out these different speed measurements there are a few key questions to help you figure out the differences:

- Does the measure include losses or not? I.e. does the time include delays like breakdowns, defects, speed losses, and so on or not? The ratio between these two times would be the OEE.

- Do you measure a time per part, or its inverse of parts per time, or only a time? Depending on the answer you have a unit of time per piece, pieces per time, or only time without any pieces, e.g. the time it takes to go through the process(es). I.e. the difference between the time between parts leaving the system or the time they stay in the system.

- Is it the actual time or the target time? I.e. do you measure how fast your system/process should be or how fast it actually is?

- Do you look at a single process, or do you look at an entire system?

- Do you need the average, a maximum, a minimum, a median, or a percentile value? In most cases you probably use the average, or more precisely the arithmetic mean, although the median can also be useful sometimes. However, sometimes there are situations where you are looking for a maximum value, i.e. if you promise your customer a delivery date, you better use the maximum lead time, or a lead time that you are 95% sure you can reach (95 percentile).

- Do you measure the average of all parts, or separately for every part type? The number of parts per hour will be different if you include all part types, or if you focus only on part 08/15.

- Do you mean an absolute or relative time? I.e. is it a time stamp (like June 15th 7:33 AM) or a duration? For the remainder of the article whenever I discuss times I usually mean a duration.

- For batch processes: Do you measure the average time for a single part or for a batch? If you bake a batch of 100 pieces in an oven, the time per batch is 100 times the average time per piece.

- Do you include some additional times on top of the speed? This is common for setting targets for manual work. The operators sometimes have to go to the bathroom, or need small mini-breaks. In any case they cannot work continuously at 100% as a machine could. Hence, the target speed is increased by an additional percentage to cover these times (often between 5 and 20% depending on local regulations and union negotiations).

As you can easily see, there is a plethora of possible speed measurements out there. Luckily, not all of the 768+ combinations of the questions above are useful in practice. A brief overview is given below for the first four questions:

Some are more common than others, but it definitely has a lot of potential for confusion. Let’s have a look at the most frequently used measurements. For the sake of simplicity I use discrete parts for my examples below, but you can easily adapt it for continuous production in process industry, e.g. if you produce liters of beer per hour 🙂 .

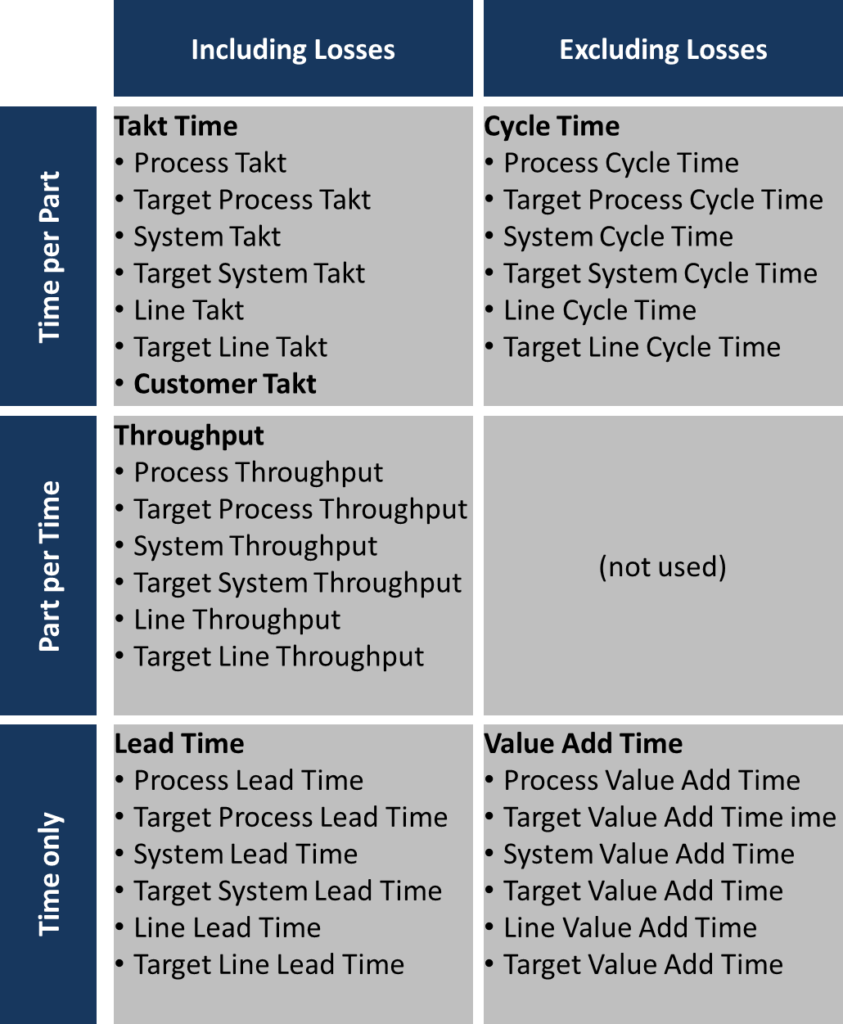

On a suggestion by Ashok Motwani I also added a table with the different times. The customer takt is in the upper left field.

Different Speed Measurements

The Takt Time

The takt time is probably most well known for the customer takt. The customer takt is the available work time divided by the customer demand during this time.

\[ Customer \; Takt = \frac{Available \; Work \; Time}{Customer \; Demand \; during \; available \; Work \; Time}\]Please keep in mind that this is of course an average time between customer orders. In reality, the customer will order much more erratically. You can also calculate the takt for a single process or an entire manufacturing system. It is important that this always includes the losses! This is useful if you want to find out if your system is able to satisfy demand.

You should also distinguish between the target value and the actual value. For example, if you determine that your system has produced 6000 parts during the last week with 40 working hours, your system or line takt is 24 s/part. If, however, you would have needed 7200 parts, then your target system/line takt is 20 s/part, and your system is too slow. If you have two machines in parallel producing parts, then your machine takt or process takt is 48 s/part but your target machine takt or target process takt is 40 s/part.

Also, please be aware that quite a few practitioners call takt time for processes cycle times! This has lots of potential for confusion! I strongly prefer to use cycle time only for times without unplanned losses or delays – see more on cycle time below. In any case, if discussion takt times and cycle times with someone else, please verify what they are talking about! For more details see my posts How to determine Takt Times and Pitfalls of Takt Times.

The Throughput

The throughput is simply the inverse of the takt time, although usually only used for actual or target production, and only rarely for the customer demand.

\[ Throughput= \frac{Parts \; Produced \; during \; available \; Work \; Time}{Available \; Work \; Time}\]It also must include losses. Hence, you can also have a system or line throughput, a target system/line throughput, a machine or process throughput, or a target machine/process throughput. This naturally must be measured in parts/time.

The Cycle Time

The cycle time is like the takt measured in time/part. The important and often confused difference, however, is that the cycle time does not include losses! The cycle time is the fastest repeatable time in which you can produce one part. I.e. it is an idealized time that you need per part if everything goes perfect, having no breakdowns, quality defects, or other problems (for more on losses see my articles on OEE).

Hence, you cannot simply divide the production time by the number of parts, but you do have to measure every part individually, and figure out what your system can do under ideal circumstances. Here you may choose not to use a mean, but instead use a median, or even a lower percentile, e.g. speed of the 10th percentile. Please note that you can add means to get the mean of the lead time, but this does not work with medians or percentiles.

Cycle times are usually measured for individual processes, where you have both a cycle time for the current state and a target cycle time for the speed you actually want. By the way, the difference between the cycle time and the takt time of a process is the OEE.

It is also possible to calculate a system or line cycle time for an entire system. You would have to figure out how fast the system would be if there are no losses. If you have only sequential processes with each process cycle needed only once for the final product, then the system cycle time would be the slowest/largest process cycle time. Similarly, you can set a target system/line cycle time. However, due to the interactions of the losses in the processes that slow down the system in reality in my view it is difficult to use a system cycle time number in a meaningful sense.

If you have batch processes, you also would have to distinguish if you are measuring the time per batch or the time per part. Depending on what you use the measurement for either one may make sense. If you want to figure out how fast your batch process should be, then of course you set the cycle time for the entire batch. If you want to find out if your batch is fast enough for the customer, and your customer takt is in individual pieces, then you would need the cycle time of an individual part, and see if it is fast enough for the customer takt if you also include OEE losses.

Please be aware that this definition above is far from universally accepted. Some practitioners define cycle time to include losses. However, based on a discussion on the LinkedIn Group TPS Principles and Practice, cycle time is more often defined excluding losses (Many thanks to all who contributed in this discussion).

For more on cycle times check my posts How to Measure Cycle Times – Part 1 and How to Measure Cycle Times – Part 2, as well as Cycle Times for Manual Processes.

The Lead Time

The lead time is the time it takes for a single part to go through the entire process or system. Therefore, this way of measuring production speed is quite different from the takt time, cycle time, and throughput above. The takt/cycle times is important if you want to know if you can produce enough. The lead time is important if you want to know if you can deliver on time.

If your cycle time is good but your lead time is not, then you will have enough but too late. On the other hand, if your lead time is good but your cycle time is not, you will build up unprocessed orders which increase your lead time and hence you will have neither enough nor on time.

Similar as with the cycle times, we have a process or machine lead time, a system or line lead time, and of course all of them also as target values: target process/machine lead time and target system/line lead time.

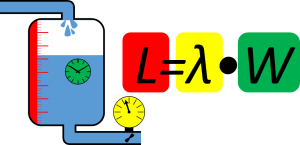

To measure the lead time of parts directly is in practice quite difficult. However, there is a very cool fundamental law in production systems that allows you to determine the lead time based on the throughput and the work in progress (WIP): Little’s Law, with

- L – Inventory, measured, for example, in units or quantity

- λ – Throughput, measured in units or quantity per time

- W – Lead Time, measured in time

This is actually one of my favorite equations in lean manufacturing, since it is valid everywhere as long as you have a stable system (i.e. no ramp up or other system changes). Read my Eulogy for Little’s Law for more details.

What about Process Time?

Another term often used is process time. However, here it gets a bit confusing. Some see process time as the sum of the cycle times in a series of processes, i.e. excluding losses. Others use it as a synonym to lead time. Yet other describe it as a synonym to cycle time or sometimes also takt time. Again other definitions I have read in my view confused more than clarified, calling e.g. the process time a part of the cycle time. Overall, I tend to stay away from using the term process time since it is too often confused.

Summary

These above are the most commonly used measures to express the speed of your system. The way of measuring depends of course on what you want to do with the measurement. However, there are more pitfalls when actually determining these numbers, which can make or break your improvement project. Hence, I will go into more details about measurements in the following posts. Please also be wary about the confusion on the nomenclature, and lots of people have different names for the times above! While these are a lot of different numbers, I hope this helps you to avoid confusion on what is what, even though the terminology in the field is highly inconsistent! So, do not get confused, but go out and organize your Industry!

PS: While writing this post I had input from different members of the LinkedIn group TPS Principles and Practice. Thanks to everybody who shared their views!

PS2: Michel Baudin added a commentary on my “useful and well researched” post on his blog. I agree with his comments and have updated the post above to include most of them. Thanks, Michel 🙂

Hi Christoph,

Good post about the different measurements of time and agreeing on the definition of important terms.

On the batch size time, does the baking analogy hold? Doesn’t it take only slightly longer to bake a batch of 100 than it does to bake 1?

Hello Edythe. If a batch of 100 pieces takes 100 minutes, then you get an average of one piece per minute (although not in a steady pace). Hence the time per batch is 100 minutes, and the time per part is 1 minute. Both is possible, depending on what you use the data for. It becomes dangerous, however, if people mix these numbers up, and e.g. set the rest of the line to 100 minutes per minute even if they don’t batch…

RT : On the Different Ways to Measure Production Speed – http://t.co/6700T8H7Tm #leanproduction #lean http://t.co/h4VsYevT9q

There is a much better way to measure production speed. it’s called “Manufacturing Velocity”. It’s a measure of how fast the materials under process are moving towards a despatchable state.

It’s obtained by the equation: Manufacturing Velocity = ∑ cycle time plus setup time divided by Lead time. It’s the summation of all the process cycle times(Floor to Floor time) and Setup times divided by the Lead time. The maximum manufacturing speed is numeric 1, obtained when the Lead time is slashed to match with the numerator in the equation. This ideal state is never obtained due to waste in the system. Typically the velocity in most “excellent” manufacturing systems excluding continuous process industries like refineries is 0.01.

The only job of a manufacturing executive and the CEO is to get rid of the waste in the system to always try to hit the Bulls eye the magic numeric 1 ; the highest manufacturing velocity

Hi Fazal, I did not know about “Manufacturing Velocity”. However, I cannot quite see where I would use this number for an improvement process. It seems to be too many metrics combined into one. I have seen a similar measurement without the set up time (with usually less than 1% value added time). The problem probably is that the set up time is irregular, depending on the lot size. In any case, thanks for pointing that out.

Hi everyone, I would like to ask if it is possible to measure the speed of agility of a manufacturing systems.

Hi Omoniyi, none that i know of. The problem is that agility is not very well defined, and even with definition you also have to consider the effort involved in changing.Usually, the more pressure, the faster the change.See also my post Facing Change in Modern Manufacturing Systems – The Difference between Flexible, Agile, Reconfigurable, Robust, and Adaptable Manufacturing Systems

Please, in attempt to estimate the speed of production in a typical agile manufacturing system, what quantifiable parameters should we look at, and how can we build a model and/or run a simulation on this? Please someone should help .

are you familiar with a term I believe is called The Stretch on production lines? I am not finding much on this, but I recall reading something about it or something very similar decades ago. I would appreciate any illumination of this?

Many thanks,

armac

Hi Armac, Sorry but I am not familiar with the term “Stretch of Production Lines”. Sorry.

Hello Christoph,

Another great post!

As the definition of lead time is the time a part takes to pass completely through a system, I think it does include all of the losses.

But in the diagram up in this post you say right the opposite; that is the lead time excludes the losses.

I’m a little bit confused. Could you please clarify?

Thank you in advance,

Murat

Hi Murat … you … are … right ….. That was a mistake on my part. The lead times include losses! I have updated the image. It may take some time before the image is updated completely, but it is on its way. Many thanks for finding this mistake!