Value stream mapping is a method to create a structured image of the material and information flow on the shop floor. You often hear that a value stream map should be the first and last thing to do during a lean project. It sometimes sounds like all you need is VSM and Kaizen and you are on the road to success. This is bollocks! While value stream mapping is sometimes quite useful, it is not a universal tool.

A Bit of History

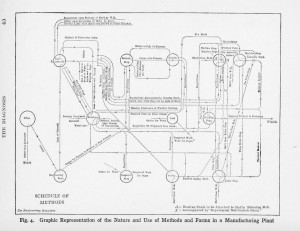

The idea of a structured diagram of the material flow in manufacturing was there long before Toyota and lean. A 1918 book Installing Efficiency Methods included diagrams very similar to modern value streams (Thanks, Bryan Lund and Michel Baudin for digging that and other details up).

At Toyota, it was called Material and Information Flow Analysis, or MIFA for short. Another name was MIFD for Material and Information Flow Diagrams. There it was used mainly at the internal lean consultancy group OCMS. From there it made its way into lean manufacturing.

The bible for value stream mapping in the Western world is the best-selling book Learning to See by Mike Rother and John Shook, published in 1999. They also coined the terms value stream mapping (VSM) and value stream design (VSD), and defined the most commonly used set of symbols in value stream mapping.

The modern Western view of value stream mapping stems from this book. However, it almost took on a life on its own, and in the Western world, VSM nowadays features much more prominently than the authors ever imagined, and sometimes even more than they wanted (more on that later).

Why Are Value Stream Maps so Popular?

About the Importance of Value Streams

Often, you hear that value stream maps are the beginning and the end of lean improvements, they are your alpha and your omega, they are your morning and your night, your ying and yang, your A and Z, your … This is bollocks!

The benefit of value streams are by far exaggerated in the Western world. At Toyota, in fact, they do very few value streams. They prefer to work directly on the shop floor.

While I like value streams and use them frequently, I personally find that the Western world puts too much emphasis on value stream mapping. Many invest too much time in making a value stream and then have no time or energy left to actually improve the situation on the shop floor.

I have seen companies where the bonus of the plant manager depended (among other things) on how often per year the plant updates its value stream. Once per year was lame, twice was acceptable, but only with four plant-wide value stream updates per year did the bonus start to look good. Hence, two to four times per year, all shop-floor-related management spent a day drawing value streams. They were rarely used for anything useful, except to improve the chances of a promotion for all involved. In my opinion, these value stream maps were a colossal waste of resources.

Again, value stream maps can be very useful if applied to the right problem. Doing them “just because” is a colossal waste of time!

Then Why Are Value Streams so Popular in the West?

At Toyota, improvements on the shop floor are done by people from the shop floor, and they know it very well. In the West, lean projects are often driven by external consultants. These consultants (hopefully) have a lot of experience in improvement projects, but chances are they have little knowledge of your products and know even less about how you make them.

Hence, they need to understand the shop floor first. However, imagine the consultant telling the client that during the first week of the project they’re not doing anything. They’ll only try to understand what the client knows already – how to make his products. Of course, the consultants still want to bill the client for the time they are doing nothing but learning to understand the client’s system. In all likelihood, the client would be less than impressed.

However, if the consultants tell the client that they start right away with a value stream, it already sounds much better (and much more billable). If the consultants tell the client that the value stream map is the most important thing for lean and cannot be skipped under any circumstances, it is so much easier to bill for the time and to get the support of the client to educate the consultants. Plus, in the end, the consultants even have a nice, fancy chart (the value stream map) to show the client.

Value stream maps are often pushed by consultants that need to familiarize themselves with the shop floor of their client.

Additionally, in Western companies, management often likes fancy slides and frilly charts. Value stream maps fulfill that desire. Yet, having a value stream map and improving the shop floor are not one and the same. Make sure the solution fits the problem. Besides, in my opinion, management rarely goes into the details of value stream mapping of somebody else, but rather treats it as a nice wallpaper.

So Does This Mean that Consultants Shouldn’t Do Value Streams?

Whoa, whoa, hold your horses. Do you really want a consultant fiddling with your shop floor without understanding what is really going on? Giving the consultants time to understand the shop floor is a necessity for a successful lean project! If they make a value stream map on the side, it does not hurt. Just remember that a value stream has a specific use but is not a tool to solve all problems.

However, if you merely want to bring outsiders up to date with your system, another possibility would be to give the consultants a boiler suit and have them work in the line for a day or two along with the normal operators. This also gives them a good understanding of the shop floor, possibly even more than a value stream map would. Although I imagine this may not be too popular with some consultants.

When to Use Value Stream Maps

The value stream map can give you a graphic representation of the information and material flow. This in turn can help you with both understanding and improving your shop floor organization.

When You SHOULD Draw a Value Stream Map

As with all lean improvement projects, you should first have a problem that you want to fix! Then, depending on the problem, you collect data, make different analyses, and use appropriate lean tools to improve your problem. A tool by itself is not a solution. Like many other lean tools, doing value stream mapping for the sake of doing the map won’t help you much.

A value stream map is a flow layout of the material and information flow. As such, it can help you visualize and understand the material and information flow. This can be done for the current state (also called value stream analysis or VSA) and also for the future desired state (also called value stream design or VSD).

As such, value stream maps can help you with understanding the flow of information and material. It can help you to see problems and inconsistencies. Common issues where value stream mapping is often useful are, for example:

- Designing a new manufacturing line (where it is part of the process)

- Improving the flow of material and information of an existing line in a flow shop (in comparison to a job shop)

- Determining lead times and replenishment times in flow shops (e.g., to calculate the number of kanban)

- Reducing unevenness (mura) in the material and information flow of flow shops

Please keep in mind that depending on the exact problem you try to solve, the maps can look differently. For example, if I want to determine the lead times, I count material. However, if I don’t need the inventories, it would be a waste to count them.

When You MAY Draw a Value Stream Map

For other problems, a value stream map may or may not help, depending on the details of your problem. Below are some examples of when a value stream map can be done somewhere during the improvement, but this is not necessarily clear at the beginning of the project.

- Capacity constraints

- Efficiency issues

- Finding and eliminating waste (helps you to find some, but also misses a lot. Not a perfect tool for waste elimination.)

- Cost issues

- Delivery performance problems

- Flow related problems in job shops, because the material flow is not standardized and may differ for every part. This makes a value stream map difficult to draw, and hence usually quite incomplete. You could focus on a more frequent high-value part, but this will still give you an incomplete picture. The more common parts you have, the more it makes sense to do a value stream map.

When You SHOULD PROBABLY NOT Draw a Value Stream Map

Value stream mapping is a useful tool. However, it is not a catch-all multi-purpose tool that solves all of your problem. Any issue not connected to the material or information flow is unlikely to benefit from a value stream map. Similarly, systems without a highly linear information and material flow usually do not benefit from drawing a value stream map either (for this, swim lane diagrams are more useful). Common examples of when a value stream map usually makes no sense are, for example:

- Safety issues

- Ingoing or outgoing quality problems

- Down times and breakdowns of machines

- A manager higher up wants a value stream (Okay, depending on the manager, this one may help your career, so you may move it up to the “definitely before anything else” category)

- Employee morale issues

- Supplier development

- Indirect areas, administrative areas, and support services, because they often have no structured flow. Swim lanes are much better here.

Summary

Again, get the right tools for the problem, not the other way around! Value stream maps have a lot of good uses, but they are not for every problem. Do a value stream map if you think it can help your particular problem, but not just because someone tells you to do it. In my next post Overview of Value Stream Mapping Symbols I will go through the value stream mapping symbols, including frequently found alternative versions. More posts discuss Basics of Value Stream Maps, and Practical Tips for Value Stream Mapping. In any case, I hope this was interesting and helpful to you. As always, I am looking forward for comments here or through social media. Now go out and organize your Industry!

Excellent article. Thanks!

Thks Chris ! VSM for me is , perhaps , the most powerful lean tool to achieve a cross-functional organization , i.e. , can be applied in any area.

Hi Roberto. VSM does have some limitations. It does not work well with job shops or most offices, or generally less structured flows of information and materials. More on this topic coming up in the next few weeks. But it is a great tool if applied correctly.

Bravo! No cookie-cutter solutions to problems that do not exist. Good thinking, good writing. This blog is quickly becoming a VA part of my routines, for which I make time. Thanks

Many thanks Brian. I will keep on writing 🙂

Kai – you might like to look at Paul Akers APP “Lean PD” He developed this after meeting Mr. Harada in Japan

Thanks for this once again great article.

I just wanted to make one more comment on the advantages of using a VSM. In my experience it is a good tool to get management support and alignement on what to work on. It’s often hard (even for outside consultants) to get Top and middle management to go on the shopfloor to gain a common understanding of the problems people face.

So by getting management to do a VSM workshop you get them onto the shopfloor and they will see the problems by themselfes. After having a common understanding of the problems it’s easier to commit on what to work on next.

Hi Johann, that sounds good. I think the main benefit comes from them going on the shop floor to see the “real world” 🙂

Good reading material. I would like to emphasize that in CI program, the team member participation is the main activity. When team member active participation is a main target, training/education, motivation, employee rating, organizational periodic target setting and very strong supportive leadership, idea sharing and more factors come into the recipe of Continuous Improvement. When does VSM come in then? VSM is a very effective tool for analysis and confirmation of actual situations for possible countermeasures. When using the cause and effect diagram, VSM data provides the cause and effect for quality, cost and delivery problems. With cause and effect at hand, we identify the detail of measures and

the expected results. Once put into application, VSM will then confirm if countermeasure target was achieved or not, if steps of countermeasure was adhered to or not and most importantly, if target steps were not executed properly, is there possibility of repeat or is it necessary to set new steps/ countermeasures?

Therefore, VSM provides details, values, and the almost complete situation of the particular subject problem and countermeasure directions. It is knowledge then! Knowledge that provide members a good understanding of the analytical process and details. And when members understand, they are motivated and encourage to participate and share each of their ideas. Sharing cannot occur if members are not motivated with knowledge. It was mentioned how some companies hire consultants who provide directions and often push the team to participate with or without confidence by virtue of their own knowledge shared by internal trainors or facilitators. VSM is a very powerful tool for analysis, for knowledge and for reference. One most difficult factor in terminating a problem in a business environment such as manufacturing is recurrence and unfinished measures. A well done VSM can increase the achievement factor. Teach VSM then.

Hi Danilo, thanks for the input. I agree, almost everything in lean is about people. VSM gets people on the shop floor to understand the situation and to see if it is better afterwards. Thanks again. Chris.

Yup, VSM is not the fix all, and you are right you need to bound the map or it may become so big / incomplete it is not a valuable. I believe the best solution in application of lean starts with distilling Managements vision of what they hope to achieve. Specifically, because often management does not have a vision but only that they need to do lean.

Then take this vision to the people and seek the low hanging fruit. What is their number 1 waste… of time, then try and quantify the waste in ### / $$$. This can be done one on one or in a team setting explaining the merits of lean with examples of successes in lean applications. Also this is the time to share the vision our management has for our lean mission.

Often just having developed rough numbers for peoples waste and just listening to them will provide more projects than can be facilitated so with your rough numbers apply Pareto and look for the biggest bang for the buck. That said don’t let the little no cost sharing of best practices miss the list because often folks in one area have a nugget of gold to share with a team right next door. Communication is another hotly missed tool in the application of lean sharing of best practices.

Totally agree, John. Management involvement is often lacking in the west, and communication across departments is also often limited. Thank you for the extensive comment.

In my experience VSM is useful in seeing the big picture so as to avoid working in isolation on shop floor projects that may actually conflict with each other. In a large enterprise it is very difficult to “see” the whole thing on the shop floor. Both are necessary.

Thanks for very interesting article. I support what you said and I agree that VSM very difficult to use for job shop.

I have another question. What do you recommend to use for job shop instead? Which tool do you believe is the best?

Thanks.

Hello Vladimir, the truth is that I don’t know yet a good diagram for Job shops. I usually approach it using a matrix of parts and processes, although this also has some problems with loops and alternatives. Another option is to – sort of – force a VSM on it if you have a product or product group that is more common than others.

Hope this helps.

“As with all lean improvement projects, you should first have a problem that you want to fix!”

Actually, identifying the target condition should be one of the primary uses of the VSM. So, you may not know the problem you want to address when you begin your VSM. The power of the Future State VSM is in setting a strategic course for improvement. (Not a random haphazard one). The kaizen bursts on the FSVSM are what point you to the strategic improvements that need to be made in order to achieve the target. You know you have problems, but you won’t know which ones to attack without VSM.

See Rother’s latest book – “Toyota Kata”.

Hi RMiller, in my view VSM is good at identifying only a few type of problems connected to the information and material flow. Hence, i do not use VSM to find problems in general. Toyota, for example, is probably one of the best companies in the world to find and fix problems in manufacturing – yet they use very few value stream maps (called MIFA’s at Toyota).

VSM is a tool to identify Current State. The Future State VSM identifies your targets or goals. The difference between Current State and Future State is the Waste that needs to be identified and eliminated to meet the desired goals. Eliminating the Waste is Value Added while drawing VSM’s is an activity to help in the Continuous Improvement Process.

Hello John. In my view, VSM is able to identify only some of the waste, but not others. Hence, if waste elimination is your goal, there are better tools out there (e.g. waste walks). Toyota does very few VSM, but is very good at finding and eliminating waste.

Nice series, thanks for writing this up.

Hi

Great article. What tool would you recommend for identifying systemic problems in a transactional environment?

Hi Niru, most of all common sense. Which tool you use depends on the problem you have. You could use fishbone diagrams, mind maps, brainstorming, etc. to name just a few.

Hi,

currently I work on to optimize office area by removing out non-value added things that occupied the space and how best we can lay out our office. We don’t really know how to start. What do you think a suitable tools can we use to replace VSM to map our area?

Hi Akram, it seems in your case a layout is better suited than a VSM. An office usually has multiple overlaying and looping value streams that are very hard to display with a VSM.You could also do a spaghetti diagram. See Visualize Your System – Overview of Diagrams in Manufacturing for more. Hope this helps.

finally! I found an article that is more on practice rather than advertisement. Thank you for this.

I share these thoughts about VSM. It is not a silver bullet as most consultants lead their clients to believe. Most often in practice using VSM is a a waste of overprocessing. I cringe whenever I hear recommendations/requent of doing a VSM when I a macro map will do,

Yayy! Thanks for the compliments. I agree with you, too. Some companies evaluate management for doing a VSM yearly, quarterly, or even monthly, and more seems to be better for them. Cringe!

VSM with all the logic and symbols is a waste of time. Absolutely impossible to apply to complex production lines. There are no real examples of classic VSM as designed by Rother and Shook in the internet.

I’ve used the Value Stream Map before, and it’s a great method to make an ideal state and a future state after. I even designed a new productionline for a company which still worked in departments.

However, the VSM doesn’t really work in a office environment. I’ve been searching for a great alternative and found ‘Makigami’. This is a great way to check out the complete Value Stream in a office environment!

Hi Rik, sure does 🙂

Hi Christoph , I want to add some of the points in “selection of VSM”. Please correct me if I am wrong.

If the site/operation is new and not stable we should not use VSM. We should wait for it’s stabilization.

Another point is we should not use VSM in Peak Days where the situation is different when it’s not Business as usual we have to hold the VSM.

Hi devender, the question is what do you need the VSM for. If it is just to hang on the wall to impress management, then it is a waste anytime (except that it can help your career…). But if you want to improve your new&unstable or peak load system, then it can very well help you. The only reason not to use it during these times is that the optimization of the information and material flow is a lower priority than debugging and firefighting. There is no point in optimizing the flow if the entire system is stopped all the time due to other issues.

Hi, regarding VSM, is it applicable to build VSM with set of Lines?

For example,

Start -> Sub-assy A-E ->Final Assy 1 -> Inspection ->End

-> Final assy 2

->Final Assy 3

Thank yuo and Regards,

Jass

Hi Jass, it is not a problem to have branches in your VSM. Just make sure you do not lose sight of the big picture.

Exceptionally great! article Christoph, specially the “bollocks” and “when not” of VSM. Since many, up to almost all articles or blogs on VSM do a missionary on the “why do” too heavy, as almost a goal on itself, and promote to visialize/analyze all possible valuestreams and all corresponding capabilities of an organization…

Where organizations already strugle to harmonize and optimize some “simple” E2E processes with supporting systems..