In my last post I detailed the 5S method (and its variants 4S, 6S, and so on). However, knowing the theory is the easy part. Successfully implementing 5S is much more difficult, and industry is ripe with anecdotes on failed 5S implementations. Here I will give you a few tips on how to increase your chances of success. However, there is no magic bullet. Cleaning and organizing a shop floor is hard work, and keeping it that way is even harder.

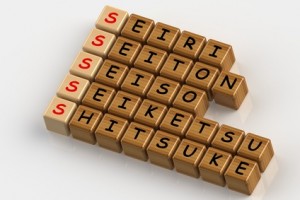

Mini Recap: What is 5S?

As described in my previous post How 5S Works, 5S is a mnemonic that can help you get a shop floor (or any other area) organized. The most common 5S are:

- Seiri – Sort

- Seiton – Systematic Arrangement

- Seiso – Shine

- Seiketsu – Standardize

- Shitsuke – Sustain

Toyota uses only 4S, and others even use 6S, with the last S being either Shukan (custom, habit, manners), safety, or security. Overall, the words, their order, and the numbers of S’s vary, but when done correctly will lead to the same results. For familiarity’s sake, I will use 5S as reference below, rather than a 4S or 6S. If done correctly, this method can help you organize your shop floor and reduce waste stemming from misplaced/old/dirty/ill-maintained tools, machines, and parts. Again, more details on the basics in my last post on How 5S Works.

Why Does 5S Fail So Often?

Examples of 5S failures are plentiful. So plentiful, in fact, that on the shop floor, 5S often has a different meaning: “Some Stupid Supervisor Said So.” Here are some reasons why 5S fails so often:

Let’s Do 1S and the Rest Should Come Automatically!

Probably the funkiest and most interesting of the S’s is #2: Seiton – Systematic Arrangement. Unskilled lean project managers just love to label everything, mark all spots, and create cut-outs or shadows for tools. It appeals to a sense of order and arrangement.

Unfortunately, in their enthusiasm they sometimes forget to first sort out the necessary and unnecessary items (#1: Seiri – Sort). They also often forget #3: Seiso – Shine, since it is so much more fun to create some new gizmos than to clean old dirt or repair damaged stuff. They may even end up arranging tools that then will not be used ever.

Hence, overall there is little improvement by doing only 1S, and it is usually not worth the effort.

Umm… Isn’t 3S Good Enough?

Okay, lets do it better. Besides #2: Seiton – Systematic Arrangement, we also do #1: Seiri – Sort and #3: Seiso – Shine, and we will even do it in order. Isn’t that good? Well, a little, but not for long. The shop floor will improve – until it falls back into its old mess shortly thereafter. Often, the improvement is usually not worth the effort.

Hard core lean purists still would condemn you to the circle of hell reserved for bad lean implementations. However, I believe that 3S can be an improvement. After all, doing all 5S is not that much different from doing 3S very frequently. Yet, if you do 3S only once, you fall far short of the potential improvement. If you include the time and money for improving the shop floor once, only to have everything revert within one month, it may not be worth the effort.

Hey, We Can Do 5S without Those Annoying Shop Floor Workers!

No, you can’t! Since it looks easy, there is a temptation to do it without involving the employees on the shop floor. However, anything you do on the shop floor should involve the people there. How would you know which tools are necessary and which ones are not (#1: Seiri – Sort)? In what way would you determine a good placement for the items (#2: Seiton – Systematic Arrangement)? Finally, the #3: Seiso – Shine is something the workers have to do regularly, so you best involve them early on.

But Consultants Always Start with 5S!

No! Definitely no! Bad consultants do love to start with 5S. So do inexperienced lean project manager. And especially bad, inexperienced lean consultants!

5S is a very quick and easy way to create some nice colorful changes that impress the person on top who pays the bill (and who often also has little shop floor connection). Cleaning and marking a shop floor also usually lasts long enough for the consultant to charge the client. The inability to sustain it afterward is then no longer a problem of the consultant, but the client (i.e., you!).

In short, doing 1S–3S is easy and can look very good, but it is so much more difficult to sustain. It also often lasts only until the consultant is gone. Additionally, not all lean consultants really know lean, and may be trying to do good but lack the knowledge.

In any case, if you have enough money to pay someone $3000 per day to teach you how to clean your shop floor, then, well, okay… call me. Although I would prefer to use my paid time to your advantage. In any case, during my consulting time, we never did 5S on its own, and I do not plant to start it now.

Where Not to Do 5S

5S can be incredibly useful if done correctly. However, even if done correctly, it is not something to do everywhere. Let me give you one example: During one of my employments, one of my colleagues had the great idea to do “5S with our office briefcases.”

He wanted to get identical briefcases, add foam inserts so every marker and pen would have its 5S place, and standardize it across the group. Let me tell you clearly why this is a bad idea:

- 5S is to help people find tools quickly. I know my briefcase. I know the stuff in my briefcase. Hence, 5S won’t help me getting better organized.

- If anybody else sticks their hand in my briefcase, they are in trouble!

- Since I carry my briefcase around the world frequently, I try to save on weight and volume. Foam inserts and a new box-style briefcase are not things I want to lug around.

- I don’t use text markers in my brief case.

- I would have no space for my flashlight, which I use frequently.

- The effort of sticking stuff into foam inserts and pulling them out again by far exceeds its benefit for me.

Similarly, you can also find examples of 5S on office desks. Over-eager consultants have marked and labeled the spots on the desk for stapler, hole puncher, pens, etc. This is nonsense! Besides, other research shows that, especially for creative workers, the paperwork on their desks is a sort-of brain extension. Hence some degree of messiness helps them think better. Overall 5S is good for shared workspace but has limited use for private workspace like someone’s desk – and especially my briefcase! Luckily for me and most of my colleagues, the idea of a 5S briefcase never materialized.

How to Make 5S Stick

After going through many different ways to fail, here are some tips on how to make 5S actually stick!

Do Not Do Standalone 5S Projects

It is much better to do 5S as part of another, bigger project. For example, if you optimize worker efficiency by rearranging the workplace, improving the material flow, or establishing a new manufacturing line, 5S will come much smoother as part of the natural flow. The workers will see 5S not as a nagging mom telling them to clean up the room (and yes, we all know how that feels), but as part of a bigger piece of improvement.

Pick Your 5S Playground Carefully – Where is It Useful?

Do not do 5S for people’s private workspace. No matter if it is a desk, a machine where very few people work, or especially my briefcase. 5S can help in work areas where many people, often in different shifts, need to access the same tools. It can also help with shared tools, as for example cleaning equipment.

5S can also help if your tools are sensitive or your products fragile. For example, if you own a nice expensive camera, you most likely own a padded camera bag to protect your gear. Putting the camera back in its bag may be part of your 5S routine.

Involve the People

When doing 5S, involve the people of the area you are optimizing. With their knowledge you will achieve a better result. Even more important, the chances of sustaining it are higher. Unless you want to clean the shop floor yourself all the time, you need the cooperation of your people.

5S can work if people take responsibility of their own environment, but management also has to give them the responsibility. All too often 5S is a management project forced on the operators, resulting in lots of activity with little improvement.

5S is Hard Work, Especially for Management

A shop floor is in this aspect very similar to an apartment. Cleaning it once is pretty straightforward. Keeping it clean is not. It is a constant effort to keep it clean. This also means it is a constant effort for management to pay attention to it. Hence, unfortunately, 5S is not a “fire and forget” method that you set up once and then forget about it. Instead, management has to check if the shop floor stays clean, and has to start countermeasures if not. The last two S’s, self discipline and standardize, are not only on the shop floor, but especially at the management level.

Update Occasionally

Over time, your shop floor will change. New tools are needed, old tools will go out. Every now and then, the first two S’s (sort and set in order) need to be repeated to bring your shop floor up to date. #3 Shine should be done regularly anyway. As for how often to repeat, it depends. Again, lean purists may say monthly, but I think this may be too much, depending on the level of change on your shop floor. Use your common sense here (and hopefully everywhere else too).

In any case, if you do the first three S’s regularly, you get the last two for free 🙂 . Now go out and organize your industry!

By the way, Mark Graban did a nice Lean Office and 5S Gone Wrong parody video, so if you have time, watch it:

Hi Christopher,

Good article. I agree with most of what you’ve said above, especially about including the workers and keeping it out of the office. The suggestion that “doing all 5S is not that much different from doing 3S very frequently” is questionable. I believe that the greatest benefit from a 5S initiative is the 4th S – Standardize. If done correctly, standardizing promotes employee involvement along with continuously looking to make things better. Moreover, not putting standards in place leaves a gaping hole for everyone to know what is expected in which case there’s no way to hold folks accountable. Standards are a must for making sure everyone is on the same page. Without them, you’re doomed to disgruntled and confused employees and a failed 5S program.

David Visco

The 5S Store

Hi David,

Thank you. I think we agree that standards are necessary, we just disagree which “S” it is in. For me, the first three S automatically include the standard of doing it. For example Toyota has only 4S, none of which is “Standard”, and it works perfectly (see my last post How 5S Works).

Yet, I am also fine with you placing “Standard” as the 4th S. As long as you do standards, I don’t really care which S it is in. If #4 works for you, by all means do it!

Again thanks for the input 🙂

Cheers,

Chris

Great article. I would say you made this whole 5s religion stick to the ground. I loved the part about the consultants. Why? I am one of those ones saying NO to the client’s 5s preference in first go. They, Clients, injected with some flavour of lean and 5s nice- and-easy-toy tend to follow conferences gurus selling their experience on 5s as a cure for everything. The results are: clients wont pay for a 5s trick again and even worse scenerio comes after – they are unwilling to start the Lean journey. This is what happens in Poland. Regards mariusz.szymocha@leanpartner.pl

Mariusz, thanks for the feedback and the stories from your experience. There are a whole lot of “Golden Calfs” in lean religion, many of whom are in my view way overblown, (5S, VSM, Heijunka, zero defects, zero inventory, etc to name just a few). Through my blog I try to get more common sense out into lean manufacturing. Great that this is appreciated 🙂

Hi Prof Roser! It’s going to be a long comment…

Here’s a bit of trench experience from a factory worker that worked in several different plants in a span of a year on the actual shop floor in California, US(Hint: Me)

The absolute biggest problem with 5/6S is the fact that the managers who have the real authority to make the real decisions tend to have absolutely ZERO factory work experience. As such, they only tend to notice things like how clean the shop floor is, or if things are “properly” labeled, lest a “dumb” worker be unable to tell the difference between a 1/2″ air impact wrench and channel-lock pliers, and waste precious production time looking for the proper tool unless both of them are correctly labeled…

For what it’s worth, the first two of the 5S go hand-in-hand. Getting rid of all the useless crap that’s doing nothing except taking up space and getting in the way only makes the job easier. As far as the operator is concerned, the main idea of the 2nd S is to arrange all of your tools and parts in a fashion that makes your work fast and easy. For example, I used to work a station inspecting steel drums’ interior after the wash. Check for things like rust or leftovers and such, and put in the plugs into the clean drums. A very common problem was having other people’s stuff piled up on the work bench due to no other place to put it. One day, I went to another line and saw that its lead had a few storage bins gathering dust. So I borrowed one, screwed it down to the wall next to the workbench, and wrote a note that all the crap not needed on the bench goes into “this” bin. Problem fixed practically overnight.

Operator’s rule of thumb: All of your tools/parts should be no more than half-an-arm’s reach away with minimal bending/turning as you work. Ergonomics and individual physical characteristics matter a lot on this one. An arrangement that works well for a short right-handed person may not be appropriate for a tall lefty. Shadowboards don’t do this very well, but they are extremely helpful when a plant runs on multiple shifts and there is a need to make sure that none of the tools are missing for the next shift. Just have the operator arrange their tools as they see fit during the shift, but be sure to put them back on the shadowboard where they belong before punching out. Like that tool drawer in the picture above. It’s obviously way too many tools for one station, but a very easy way to tell if a tool or two “walked off the job” during a shift.

Now, the 3rd S. I’ve seen it done well, done badly, but mostly badly.

One plant I worked at, there is a line that was washing plastic 55gal barrels. The floor is grated steel, while all the water from the pressure washer and the rest went down onto a catch-pan below. A pump would suck up all the water it could and put into the rinse tank. All would be well, if it wasn’t for all the dirt sediment and paper shreds collecting down below. And the catchpan being uneven enough that dirty water pooled up everywhere. The upper management weren’t too happy about the dirt and had us clean it. Too bad there is only just about enough clearance between the catchpan and the grated floor for a person no more than four feet tall to do the job comfortably (I’m 5’10”). Ugh!

Another plant I was at did it a little bit better. There was a policy that everyone is to stop the work and take five minutes to clean their work areas before the scheduled break/lunch. We had squeegees and sweep brooms to do all of that. One of the supervisors noticed that we could clean a lot more thoroughly if we used the brooms and took 3x more time instead of using the squegees. The squegees disappeared overnight (except the ones we hid ahead of time).

Here’s another story from the plant above. In USA, there are about a trillion different regulations for food plants, and cleanliness is a big part of it. I was working the corn mill machine. One of the gaskets got loose and was leaking water and presevative into the masa (dough). Nothing too harmful, really, but very visible due to the machinery being cleaned every night. I saw our lead having a casual conversation with the supervisor. I went up to them and said something like “Hi, I hate to interrupt the romantic moment, but my machine is leaking oil into the masa. What do I do?” After those two saw what was happening and the supervisor freaking out about regulations, me and the tortilladora operator got to spend half an hour to thoroughly clean our work areas 😉

Some suggestions for the managers to make 5S (especially the 3rd S) stick from the bonafide factory worker:

-Provide cleaning equipment that is actually suitable for the job. There’s absolutely nothing worse and demeaning than having to clean up stuck on grime with a dainty-ass kitchen broom while knowing that having a pressure washer at hand could accomplish the job three times faster, three times easier, and with better quality. See the paragraph about the sqeegees on the same. Ditto the same for having enough brooms and dust pans so that half the guys aren’t running around looking for a dust pan.

-Don’t make the guys constantly clean up the messes from the processes and machines that are just plain messy and never designed with cleanliness in mind to begin with. If a wash machine leaks everywhere because it’s older than I am and half the pipes are corroded out, fix the machine! Don’t tell me to police up the spills on top of everything else I have to do!

-Give the workers extra time needed to properly clean/inspect their work areas instead of expecting everyone to fit that in on top of the production quotas.

-Encourage/change work habits that affect the amount of cleaning to begin with. I ran into that one myself a couple times. I worked at a plant that was assembling pool equipment. The area I was at was responsible for labeling the motors, attaching backplates, and such. I was throwing backing paper from the stickers all over the place until a co-worker told me to take it easy, and drop the garbage onto the cardboard. Once all the motors were done, carefully fold the cardboard and put it on the recycle cart along with all the rest.

-Since the real goal of the 3rd S is to “inspect as you clean”, make the workers free to “get out of” cleaning by identifying and fixing actual problems in the area e.g. “Yeah, the floor is kinda dirty, but the brush on the grinder is way past worn out, and the bin for the 2″ plugs needs to be topped off. The next shift will run out of those in less than an hour into the shift. Should I wipe down the bristles on the grinder brush or go to the storeroom to get a new brush and a box of plugs?”

All in all, in my personal opinion, if you get the first 3S’s right, the Fourth and the Fifth will come naturally. Sorry for the long comment.

-Andre.

HI Andre, that was indeed a very long comment, but absolutely worth reading!!! I liked your examples. I also shudder at the four feet clearance for the washing area – i am 6’2”. Excellent comment, and actually almost as long as my main post. Thank you VERY much for the input!

Chris

Great Article for me to read. I am a new site Lean leader for a factory of 600. I loved it, and loved Andre’s comment. I am very, very close to people on the production floor because I spent more than half my time there or as a line worker and eventually a lead operator.

I was very close and still am close to the floor folks. Without them we are nothing and I don’t care what anyone says–that’s the truth. I want 5S to work, I want it to be our culture but I refuse to make implement stupid into 5S! We had that the first time around. We had blue tape to mark out everything…yep–just like your desk picture. The floor was the same way. It was heinous and was completely was a joke to the floor folks.

As the leader of one of those early 5S kaizen, I actual did a tape outline on the floor of a worker laying down pretending to have died of 5S exhaustion. We also made foot prints next to the machines as a joke, and butt outlines on the chairs where their butts should be. Don’t worry, it was on 3rd shift, no big shots around at 3 a.m. and it was all removed by morning. The employees loved my involvement in the naughtiness and it totally enlightened everyone’s sour mood.

Hi Brenda, I like the humor of your workers. 5S can be too much if it is done just for 5S’ sake…