In the last post, I started with the basics of a CONWIP system, where CONWIP stands for Constant Work In Progress. However, there are some more frequently asked questions that are also important for CONWIP. These I will explain here.

Initially, I wanted to write one quick post explaining CONWIP. However, as it happens all too often, one post turns out to be not enough. It quickly expands into multiple posts of a series in order to give you a good, well-rounded overview of the topic. Hence, the frequently asked questions will be covered in two separate posts. After that, the fourth and truly final post of this series will discuss the advantages and disadvantages of CONWIP.

If you don’t yet know much about CONWIP, check out the basics of a CONWIP system for an easier understanding of the following discussion.

Frequently Asked Questions on CONWIP – Part 1

What is the Sequence in the Production Line?

The manufacturing line should still be using a FiFo system, where the first part that goes in the manufacturing system is also the first part that goes out. Spearman et al. more generally speak of a “First in System, First Served” approach. The card with the oldest time of entry into the system (the matchmaking time) gets produced first.

For flow lines, this is no problem at all, as most flow lines usually include some sort of FiFo by default. However, this also works for job shops (see another question below).

Spearman et al. also suggest that this rule must be followed, except for rework. The assumption is that rework is long past overdue and therefore has to rush through the system. In my view, this is one possibility to break FiFo. However, there may be others (see my post Theory and Practice on FiFo Lanes – How Does FiFo Work in Lean Manufacturing in the subsection on “Breaking the Rules”).

I can also imagine incorporating a priority system for normal parts. For example, it can make sense to always give exotic parts priority over high-runners to reduce the overall inventory for unchanged delivery performance. In any case, you should have a rule to ensure that no part is forgotten in the system. If it is entirely up to the operators, the more difficult/less pleasant/less productive parts may be forgotten for the next shift indefinitely.

What Happened to the Supermarket?

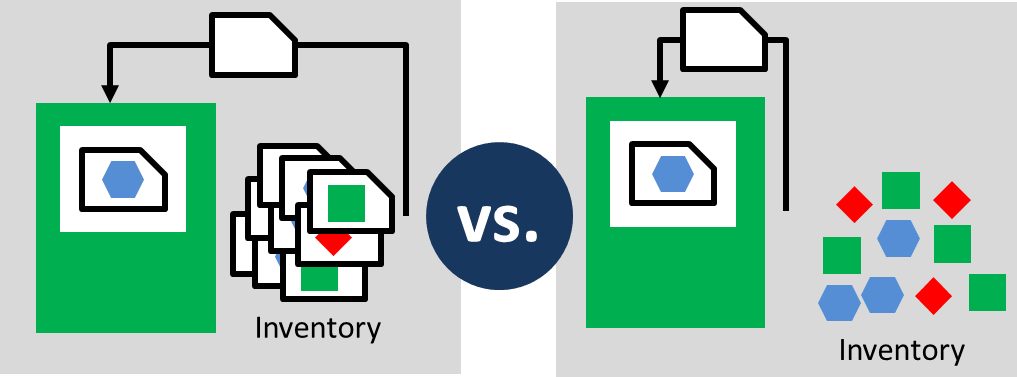

A kanban system has a supermarket at the end of the loop. A supermarket ideally has a line for each product type, similar to many parallel FiFo lanes, one for each type. Of course, a CONWIP system can also work without a supermarket, where there is just a general inventory at the end of the loop.

However, if you still have some high-runner products, it may make sense to have at least some aspects of a supermarket included at the end of the loop. At a minimum, if there is more than one of a certain part type in the finished goods inventory, the one with the oldest CONWIP card should be sent out first.

In any case, similar to the supermarket, the CONWIP cards return to the beginning if they leave the last inventory in the system. Unless, that is, you choose to return the card before the part enters the last inventory. For this, please see the next question below.

When Exactly Does the Card Go Back?

Good question. The literature does not quite agree on that. Two options seem to be used: Return the last card when the parts are removed for the next process or customer, or return the card as soon as the last process is completed.

Spearman says that “When the container is used at the end of the line, the card is removed and sent back to the beginning.” Others say to send the card back as soon as the last process is finished. Both are possible approaches.

Sending the card back when the parts are used downstream includes the inventory of completed products in the WIP control via the CONWIP system. This allows the use of a supermarket and prevents overproduction. On the other hand, this needs some more CONWIP cards, since many of them will be with the completed products. But then, just having less cards does not mean having less inventory. Merely part of your inventory has no cards. In any case, this approach will make the system compatible for a kanban-CONWIP hybrid.

Sending the card back as soon as the last process is completed will still prevent the line from choking itself. This will require less CONWIP cards. However, in this case it is possible to overproduce and make more parts than may be needed.

My preference would be to include the completed goods in the CONWIP loop (i.e., the cards are only returned when the parts are used downstream by the next system or the customer). This way we prevent overproduction, which is something I am very keen about preventing.

However, this requires care with the backlog sequence. It is possible to block the system by using up all CONWIP cards for products that are not needed and then have no cards left for the products that are actually needed. Hence, a bad backlog sequence can jam the CONWIP system. Just imagine what would happen to your CONWIP system if a higher-up manager calls and tells you to produce only part X from now on, since that is for an important customer who complained about the lack of X. <sarcasm> Of course, this never happens, right?</sarcasm>

How Many CONWIP Cards Do I Need?

Similar to a kanban system, a CONWIP system needs cards. In a kanban system, the number of cards is often subject to lots of consideration (see, for example, How Many Kanbans? – The Kanban Formula). In a CONWIP system, the number of cards is of course also significant.

The number of kanban cards depends on the replenishment time and the different fluctuations. Similar would apply to a CONWIP system, albeit it is more tricky to determine. If the produced part would be used downstream right away (common for made-to-order products), the number of cards would represent the WIP level that lets the manufacturing system run smoothly and efficiently.

However, if you also have made-to-stock products, you somehow would have to include the buffer stocks required due to demand and production fluctuations. You cannot simply take the sum of all part types, because then you would end up with the right quantity but the wrong type. Similarly, you cannot look at all part types separately (as in the kanban formula), since your CONWIP card does not have part types!

Overall, I would recommend a method similar to another kanban approach (and actually my favorite way to determine the number of kanbans). Simply use enough CONWIP cards to make sure it runs smoothly. Then reduce them as needed. If you encounter repeated problems due to insufficient cards, either increase the number slightly or make your system even leaner than it is already (see How Many Kanbans? – Estimation Approach and Maintenance).

Summary

The more I research the CONWIP system, the more I like it for exotic parts. The more I like it, the more I research it. Hence, the next post will continue with more answers to frequently asked questions. After that I will discuss the advantages and disadvantages of CONWIP in my last post on this topic (for now 🙂 ). In the meantime, go out and Organize your Industry.

Overview of CONWIP posts in this series

- Basics of CONWIP Systems (Constant Work in Progress)

- Frequently Asked Questions on CONWIP Systems (Constant Work in Progress) – Part 1

- Frequently Asked Questions on CONWIP Systems (Constant Work in Progress) – Part 2

- Advantages and Disadvantages of CONWIP in Comparison with Kanban

Selected Sources

- Marek, R. P., Elkins, D. A., Smith, D. R., 2001. Understanding the fundamentals of Kanban and CONWIP pull systems using simulation, in: Winter Simulation Conference 2001; Proceedings of the Winter Simulation Conference 2001, pp. 921–929 vol.2.

- Spearman, M. L., Woodruff, D. L., Hopp, W. J., 1990. CONWIP: a pull alternative to kanban. International Journal of Production Research 28, 879–894.

Hi,

As the Lean Manufacturing Leader for my company, I have implemented CONWIP for several lines, and WIP has seen a dramatic decrease, about 35%! However, I receive a lot of complaints about the cards, that the cards are difficult to manage, the process is cumbersome, the cards get lost and some operators don’t even abide by the rules of the process (waiting for a card before beginning the next job), etc, but in general it has done wonders. So one factory, seeing the benefit of CONWIP and not the cards, has decided to make an electronic version of CONWIP, where they manage the quantity of pieces in the loop, essentially setting a maximum piece quantity, and ensuring the number of pieces in the loop does not go above the maximum threshold, and if it does, the machine is stopped to let the WIP level subside, but it is restarted again before the loop dries out.

Any feedback on this electronic version? I am trying to keep the cards as a physical part of the process, but I am being challenged on this. What, if anything, can I say to prevent this?

Also, this electronic version is going to base the WIP level on capacity rather than our customer demand. Is this doable or is there a pitfall in this logic? As it stands today, our Daily Customer Demand is greater than our Daily capacity output, which should mean our WIP levels will stay lower if we use capacity rather than customer demand.

-Kyle

Hi Kyle, Great Success story! As for losing kanbans, check my post The Problem of Losing Kanban – Different Kanban Types, which applies similarly to CONWIP. However, i think your problem may be elsewhere. If i understood you correctly, you have a digital system, AND a CONWIP card system. This is a No-No. The process should have one and only one signal, e.g. either digital or a (CONWIP/Kanban) card. if you have two signals, the operator can and will choose whichever one he likes best. Two signals will lead to confusion and mistakes. Best wishes, Chris.

Lost KB cards is actually immanent part of the process unfortunately. Kyle, would you mind explaining the business you’re in – what kind of industry, what kind of production profile? Christoph, so far it seems like CONWIP requires fixed quantity per card irrespective from product. Do you consider different quantity levels within same CONWIP loop? I’m trying to visualize what the difference there is between CONWIP and EPEI by Glenday for example. Will CONWIP work with streams approach where different batch sizes apply?

In lean, I think there are very few fixed rules, if any. CONWIP would work best if the work content of each card is similar. Yet, this may be too much effort to manage and set up. An easier systems is that a CONWIP card permits the starting of the next job, regardless if it is a small one or a big one.