One approach to leveling (also known as heijunka [平準化], or production smoothing) is capacity leveling: Do not add more production orders into the system than what the system can handle. Try to produce the same total quantity every day. Doable for almost everybody, and one of my favorites. In fact, if you are using a pull system like kanban or CONWIP, then you are already almost there.

One approach to leveling (also known as heijunka [平準化], or production smoothing) is capacity leveling: Do not add more production orders into the system than what the system can handle. Try to produce the same total quantity every day. Doable for almost everybody, and one of my favorites. In fact, if you are using a pull system like kanban or CONWIP, then you are already almost there.

This approach is not the highest and best form of leveling, but it is doable for almost all firms. Some other approaches, notably an Every Product Every Cycle (EPEC) approach, often do more harm than good.

How to Mess Up Your System

Too Many Open Production Orders

Overproduction is one of the seven wastes (Japanese: muda 無駄). It is considered the worst type of waste, as it has negative synergies leading to many other types of waste. It is possible to keep this waste in check through a pull system like kanban or CONWIP.

However, almost as bad as producing too much is having too many open production orders in the system. One issue is that you no longer know when you produce which order. This means any priority you had when adding the production order is gone (see Bottleneck Management Part 2 – Improve Bottleneck Planning).

Since you do not know when an order will be started, you no longer know when the supplier needs to deliver its goods. What typically happens is that the person in charge plays it safe and orders everything that may be needed for any of these jobs. Raw material inventory increases. At one point that person gets scolded for having too much material and steps on the brakes. When material starts to run dangerously low, urgent orders are added again. And hence we have the bullwhip effect.

Capacity Variations

A second effect – albeit usually less drastic – is capacity fluctuations. On a big scale, there are fluctuating absences, vacation periods (e.g., school holidays), and outright plant closures during holidays.

Additionally, there are also effects on a small scale. One week the priority is on product A, and lots of the available capacity flows into product A, whereas other products have to wait. A week later the plant notices that it overshoots on A and its inventories are exploding, while product B is running out of stock. Hence it stops producing A and focuses on B. A week later the situation is reversed. A is out of stock, and B is exploding. Again, we have the bullwhip effect.

How Capacity Leveling Works

All this mess can be avoided through a pull system and capacity leveling, where you keep the number of your workers and your working times as constant as possible to produce the same total quantity every day with minimal fluctuations. (Depending on how you define capacity, you could also call it leveling of capacity utilization)

Use a Pull System

Pull systems, especially kanban, are one of the cornerstones of lean production. Produce only to replenish your inventories. This way you can avoid the negative effect not only of overproduction but also of too many open product orders. Similar systems can also be adapted for products that are made to order rather than made to stock. I have talked about kanban in many other posts, and hence won’t go into too much detail here.

Pull systems, especially kanban, are one of the cornerstones of lean production. Produce only to replenish your inventories. This way you can avoid the negative effect not only of overproduction but also of too many open product orders. Similar systems can also be adapted for products that are made to order rather than made to stock. I have talked about kanban in many other posts, and hence won’t go into too much detail here.

With kanban, such variation in product orders is significantly reduced. However, it is not completely eliminated. The two extremes in theory could be that all kanban are waiting for replenishment in front of the first process, or that all kanban are with material in the supermarket and there are no orders waiting in front of the first process. In reality, however, these situations are rare, and fluctuations are overall much reduced.

An alternative to kanban with less fluctuations would be CONWIP, where the number of jobs in the system is kept constant. However, in my view it is a little bit more difficult to implement. I will blog about CONWIP later in more detail.

Keep Capacity Constant and Adjusting the Product Mix to Produce Regularly in Small Lot Sizes

Another element in capacity leveling is to keep the production capacity used as constant as possible. This applies not only for the entire plant or for individual production lines, but ideally also for individual product types and products.

Actually, the ideas here in capacity leveling are only the beginning. Most of what is considered leveling focuses on capacity leveling, and subsequent posts will go into more detail about these, including, for example, a repeating pattern (Every Product Every Cycle EPEC / Every Part Every Interval EPEI) or One Piece Flow. However, especially the EPEC comes with a big warning label attached, as it can make things much worse than before.

But for now let’s keep it simple. Try to avoid wild swings in your production capacity for individual parts. For your high runners that have a stable regular demand, try to produce them every day. In a perfect world, this would also be the same quantity every day, but this may lead to disastrous results (see my next post). For now, simply try to produce these parts every day.

But for now let’s keep it simple. Try to avoid wild swings in your production capacity for individual parts. For your high runners that have a stable regular demand, try to produce them every day. In a perfect world, this would also be the same quantity every day, but this may lead to disastrous results (see my next post). For now, simply try to produce these parts every day.

For example, all of your waiting production orders (kanban or otherwise) represent the overall mix you have to produce. Out of these open orders, make a similar mix that matches your daily capacity. You may need to adjust for lot size. This is the mix that you should produce.

Of course, for exotic parts that are produced only once every two weeks, it cannot be completely avoided. But even then, produce these exotics once every two weeks, and do not pool it into larger batches every half year.

It helps to have smaller lot sizes. With larger lot sizes, your capacity used for individual products will fluctuate more. Smaller lot sizes help to reduce fluctuations of the used capacity by part number (see SMED for details).

Match Released Production Orders to Available Capacity

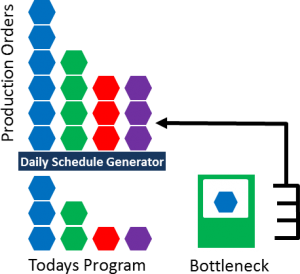

A kanban system avoids overloading the production line with open orders. However, this can be also adjusted more finely. Estimate the available production capacity for the next few days. Ideally, estimate the total capacity between today and the expected completion of the production orders that are issued today. Now compare that to the capacity that is already allocated within the same period. The production orders released for production match the difference between the available and already allocated capacity (i.e., you fill the capacity up with new production orders).

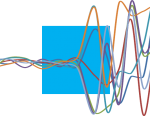

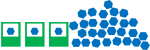

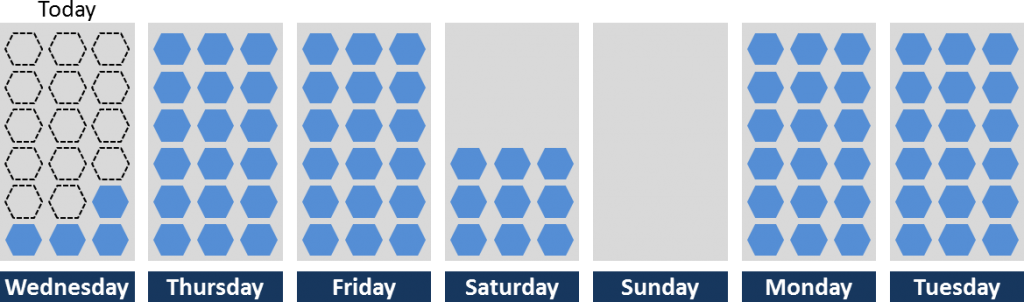

Let’s make an example as shown in the image below: If you expect that today is Wednesday, and today’s production orders will leave the production line in seven days, then your time interval is seven days. This includes not only production but also ordering and supplying of material, set ups, and so on.

Every day you have the capacity to produce 18 products, except Saturday with only one shift for 9 products and Sunday with no production. Therefore, for the entire seven-day period you have capacity for exactly 99 products.

However, you already have 85 open orders waiting or being built (the blue hexagons). The remaining open capacity is now 14 parts (the dashed-line hexagons). Hence you should add another 14 parts to the list of production orders waiting for production.

Through such a system, the open orders will always closely match the available capacity. When there are delays, fewer new production orders will be released. A surprise increase in speed is rare, but this can be handled with having, for example, one additional day of open orders as a buffer for the rare surprise capacity increases.

Of course, the image above shows only one part type (the blue hexagon) for simplicity. In reality, these open orders should of course be a representation of all product types, as explained above in the section Keep Capacity Constant.

Overall, you can significantly improve your production through leveling by using the three steps below:

- Keeping capacity as constant as possible

- Matching released production orders to the available capacity

- Adjusting the product mix to produce regularly in small lot sizes

Overall, your production will run much smoother, as will the production of your suppliers. I hope this post was interesting to you. Please let me know if you have any questions. Otherwise, go out and organize your Industry!

Overview of Posts in This Series about Leveling

- Why to do Leveling (Heijunka)

- An Introduction to Capacity Leveling

- Theory of Every Part Every Interval (EPEI) Leveling, Also Known as Heijunka

- The Folly of EPEI Leveling in Practice – Part 1

- The Folly of EPEI Leveling in Practice – Part 2

- Introduction to One-Piece Flow Leveling – Part 1 Theory

- Introduction to One-Piece Flow Leveling – Part 2 Implementation

Also, Michel Baudin wrote a post on Theories of Lean and Leveling/Heijunka on his blog with a review of my series on Leveling. Some of his comments helped me to update and improve the above post. Check his post out for further details on Leveling.

Dr.Roser,

I really love all your post which flash my views on lean and continues improvement

I am looking forwards to expecting more on Just in time (kanban ,pull ect.,)

have a good day

thanks 🙂

Again, many thanks, Felix. Writing about Pull is on my ToDo list, but I think I will also add JIT. I am always looking for suggestions on Topics to write about.

Best wishes,

Chris

Dr. Roser,

Can you please confirm my understanding? IMO capacity planning basically Each Product Each Day with sieving being done daily.

Can you write an article about capacity levelling on FMCG Sales and Distibution operation? I will be glad to implement that in my company.

Hello Alex, Capacity planning looks only at the total quantity of all products on the line. There is not yet a special mix of parts (that would be subsequent articles in this series). This should also work for FMCG, although you may have to be quicker to adjust the capacity to the demand since you cannot buffer for long using non-durable inventory.