The speed of modern business is continually increasing. Product life cycles of cars and mobile phones are decreasing, and customer demand is more volatile. Gone are the days of Henry Ford, who produced his Model T for almost 28 years without much change. Modern manufacturing systems need to be prepared for a constantly changing environment. The challenge has been realized for quite some time now, and there are a multitude of expressions related to this problem. This post will discuss many of these terms related to the challenge of change.

The speed of modern business is continually increasing. Product life cycles of cars and mobile phones are decreasing, and customer demand is more volatile. Gone are the days of Henry Ford, who produced his Model T for almost 28 years without much change. Modern manufacturing systems need to be prepared for a constantly changing environment. The challenge has been realized for quite some time now, and there are a multitude of expressions related to this problem. This post will discuss many of these terms related to the challenge of change.

Active and Passive Change to the Manufacturing System

Generally speaking, the ability of manufacturing to react to change can be grouped in two parts:

- Active change, where operators and management actively change the manufacturing system. The goal here is to have a system that can be changed easily.

- Passive change, where the system itself has a built-in ability to change. The system automatically reacts even without the operators or management adjusting the system.

Naturally, a passive change is preferable when possible. Examples for a passive system are kanban or CONWIP (i.e., any system that limits the work in progress). Using such an approach, the manufacturing system never gets overloaded but can run much smoother than a system where every order is pushed in immediately.

Sources of Change

Change in a manufacturing system is inevitable. There are different sources of change, requiring different responses to counteract its effect. In short, everything changes. Below is a list of possible sources of change in more detail.

- Machines and tools – They may age or break, disrupting the system.

- Man – Your labor force is not static, but will change over time. Are there tasks that only one employee can do? If so, you are at risk. Will you survive a strike?

- Supply – Supplies may be delayed, or a source of supply may dry up completely. Will your business survive if your key supplier goes bankrupt? Many companies use a dual-source strategy to reduce this exposure to risk.

- Customer – Has the habit of always ordering more or less than you expected, ordering different products, or even switching to the competition completely (although sometimes they also switch to you). Also has a reputation for unreasonable demands. But then, you can’t live without customers either.

- Competition – Technologies improve, and prices (usually) go down. Are you ahead of the competition, swimming with the bulk, or are you falling behind?

- Management – One of the biggest sources of change in manufacturing. On a large scale, a new boss usually means out with the old and in with the new, whatever that may be. Even on a small scale, management disrupts. It is common wisdom in industry that night shifts are more productive, since there are no managers around to change things. But then, they often have to forward changes that are forced on them by external sources in order for the company to survive.

There are more sources of change, depending on the level of detail you go into. However, the focus of this post is different aspects to face this constant barrage of change.

What the Industry is Talking About (… and What They Mean)

Below is a list of terms used to express different approaches to face change in manufacturing. Unfortunately, these terms are used differently by different researchers and practitioners. My goal is to give you an overview of what is out there:

Flexible Manufacturing System

Flexible /ˈflɛk.sɪ.bəl/: Capable or being easily changed

A flexible manufacturing system aims to produce different products on the same system without excessive changeover cost. At a minimum, this includes different products of the same product family. More advanced flexible systems, however, can also include products of different product families.

One popular example in automotive is Toyota, which was the first automotive company to assemble completely different car models on the same assembly line.

According to Google Ngram viewer, the term was very common and popular around 1990, but since then has lost its luster. The graph shows that the use of the words “flexible manufacturing” started around 1980 and peaked around 1990. Since then the usage of these words fell significantly, yet at its peak it was one of the most important keywords in manufacturing.

Agile Manufacturing System

Agile /ˈæd͡ʒ.aɪl: Having the ability of quick motionYet another popular term in industry is “agile manufacturing.” Somewhat vague, agile manufacturing aims for a quick response to changes.

Below are the Google Ngram results for agile manufacturing. The term was unknown before 1990, but peaked already around 1996, only slightly below the peak of flexible manufacturing.

Reconfigurable Manufacturing System

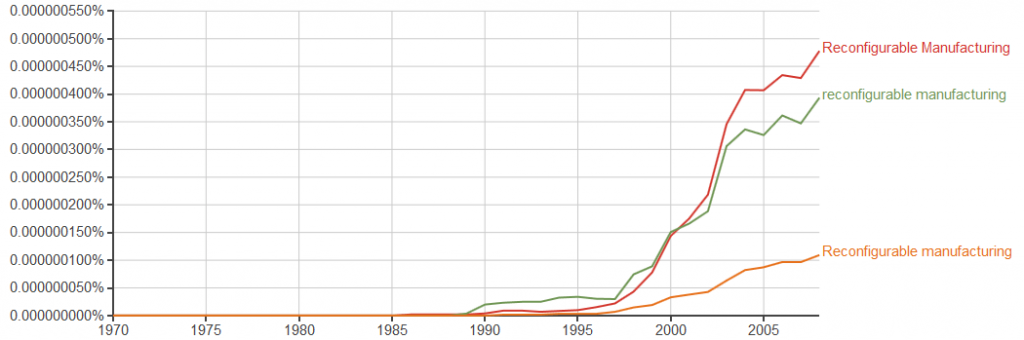

Reconfigurable \ˈrēkən-ˈfi-gyərəbəl/: Able to be rearranged or adapted, able to be set up in a particular wayThe expression “reconfigurable manufacturing” is similar to adaptable manufacturing above. The reconfigurable manufacturing system is (supposedly) also able to adjust rapidly to changing circumstances.

Below are the Google Ngram results for reconfigurable manufacturing. The term was unknown before 1990, but shows strong growth from 2000 onward. It seems that the meaning is identical with agile manufacturing above, only the names have changed.

Robust Manufacturing System

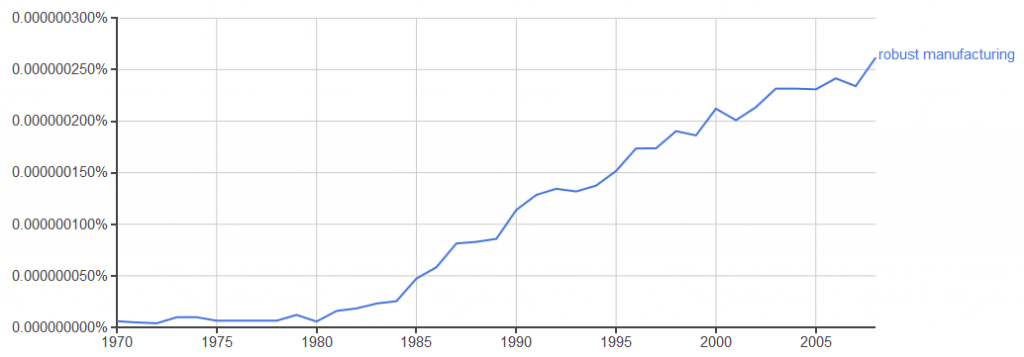

Robust \rō-ˈbəst\: Designed or evolved in such a way as to be resistant to total failure despite partial damageRobust, by definition, means that the robust manufacturing system is insensitive to problems and challenges that arise. This can be achieved, for example, through redundancies. If you have only one machine for a critical process, then your entire system is in danger if the machine breaks. The same applies if you have only one employee able to program or operate this critical machine(s) – and believe me this happens way more often than you would think.

One step up is to not only have more than one machine, but to have more than one location. For example, one of the largest cardboard manufacturers, the Mayr-Melnhof Karton AG, uses a multi-site concept in case one of their plants has to stop operations for whatever reason.

However, in industry and research, the term “robust” is sometimes also used as a synonym for “flexible” or “agile,” even though they are, strictly speaking, not the same.

Below are the Google Ngram results for robust manufacturing. Starting in 1980, the expression shows steady growth. Unfortunately, Ngram data is available only until 2008. However, from my experience, there is still a lot of talk about robust manufacturing in industry.

Adaptable Manufacturing System

Adaptable /əˈdæptəbəl/: Capable of fitting by alteration; capable of modifying or remodeling for a different purpose; Another way of saying “agile manufacturing “is “adaptable manufacturing.” However, in research, adaptable manufacturing considers unforeseen future events during factory planning. You can already include a lot of flexibility, adaptability, and robustness options when deciding where and when to install new equipment or establish new plants. Do you establish a plant in a country because it is cheap, or do you also consider that political unrest may burn down your plant three years from now? (I was thinking about naming an example country, but then there are too many that are on shaky ground. 🙁 )

The term “adaptable manufacturing “was used especially around 1990, but due to its specialized meaning even then it was only around 1% of the usage of flexible manufacturing above.

Other

There are many other terms and buzzwords flying around in industry and academia. Here is a selection of additional terms in use:

- Intelligent Manufacturing System – Sort of a catch-all of everything that is good, beautiful, and trendy. However, this also means that it has no specific meaning. The term peaked in 1995. Around this time, people jumped on the bandwagon and a research institute with the same name was founded. The phrase is still commonly used, but everybody uses it to mean something slightly different.

- Holonic Manufacturing System – Holonic stands for autonomous and self-reliant. Initially used in 1990 for systems that can adapt to new products, research now talks about self-adjusting systems.

- Versatile Manufacturing System – This term is almost the same as “modern manufacturing,” with first uses dating back to 1885. Depending on whom you talk to, this means the same as “flexible manufacturing,” or it means “automation and computers,” etc. The term is still used, but rather infrequently.

There are even more other but obscure terms like wisdom-enhanced manufacturing, self-organizing manufacturing, resilient manufacturing, or reactive manufacturing, but they are used only rarely.

In any case, I hope this brief overview of flexibility in manufacturing was interesting to you. Now go out and improve your Industry!

Sources

Ngram graphs are from the Google NGram viewer, using English language case-insensitive searches.

Hi,

I would like to know the difference between mix model line and flexible production system??

I am trying to improve a production line where we produce differents products. The differences between them are format, recipe, packaging’s sizes. We make change over every product change so I dont know if I am in Flexible production system or mixed model line. Can you recommend me books or websites to drill down more about these subjetcs.

Thanks

Hi Rene,

My post last week and my post tomorrow talk a bit about flexible production lines. https://www.allaboutlean.com/job-shop-to-flow-shop-1/ . For me, a flexible production system and a mixed model line are somewhat synonyms, both describe a line where different products can be produced on the same line with little or no changeover effort. In your case: try to get the changeover times down to a range where they no longer matter, and you can produce in lot sizes of one. Of course I know this is easier said than done …