The cost of complexity can significantly impact the bottom line of manufacturing companies. According to A. T. Kearney, the top 30 companies in Germany could earn €30 billion more if they would reduce complexity, increasing their EBIT by three to five percentage points. After discussing the cost of complexity in a previous post, using the Maybach as an example, this post describes the general levers influencing complexity cost.

The cost of complexity can significantly impact the bottom line of manufacturing companies. According to A. T. Kearney, the top 30 companies in Germany could earn €30 billion more if they would reduce complexity, increasing their EBIT by three to five percentage points. After discussing the cost of complexity in a previous post, using the Maybach as an example, this post describes the general levers influencing complexity cost.

Example: Lego – A Success Story

Reducing the number of variants can make an enormous difference in your bottom line. One highly successful example is the Danish Lego Group, maker of the famous Lego bricks. From its founding in 1932 until 1998, it made a profit every year. However, after 1998 the company went through enormous (self-made) problems and nearly collapsed in 2004.

Reducing the number of variants can make an enormous difference in your bottom line. One highly successful example is the Danish Lego Group, maker of the famous Lego bricks. From its founding in 1932 until 1998, it made a profit every year. However, after 1998 the company went through enormous (self-made) problems and nearly collapsed in 2004.

That’s when Jørgen Knudstorp took over (a former McKinsey consultant like myself). He managed an enormous turnaround, making Lego the second largest toy maker worldwide. One of his key measures was to reduce the number of different Lego pieces from 12,900 to 7,000, a reduction by almost half. He eliminated the color dark gray, leaving white, light grey, and black. The shapes of bricks now get reused; for example, the brown Lego croissant is also a white architecture element. This saved €50,000 by not requiring a new mold. He slashed the lifestyle part of Lego that sold watches and t-shirts. Even the Lego theme park got sold.

This reduction had a significant positive impact on their overall costs, and Lego is now again a very strong and highly profitable company.

Example: Automobiles – A Mixed Story

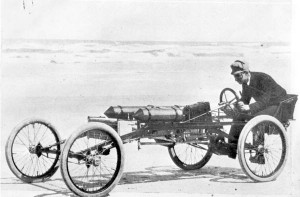

Probably the best example of a large number of variants for complex products is automobiles. In a previous post I went into great detail about the Maybach. Naturally, with automobiles customers expect to have a number of selections available to choose from. The days of Henry Ford’s Model T, available only in black, are long gone, and good riddance!

Probably the best example of a large number of variants for complex products is automobiles. In a previous post I went into great detail about the Maybach. Naturally, with automobiles customers expect to have a number of selections available to choose from. The days of Henry Ford’s Model T, available only in black, are long gone, and good riddance!

However, the number of variants still affects the bottom line. For example, both GM and Volkswagen offer a number of very similar cars under different brand names. In effect, they are competing with themselves, or – as it is called in industry jargon – they “cannibalize” themselves. They try to ease the pain by using different platform or module strategies. However, the large number of models is still a major overhead cost compared to Toyota, which sells even more cars but with much less models and variations.

Even within the same model, the number of options are relevant. For example, Mercedes offered an electrically extendable trunk floor for its S-Class. Most customers, however, viewed this as a gimmick, which is kind of obvious to me too. Even salespeople didn’t know much about this option since they rarely sold a car with it.

Sources of Complexity Costs

Complexity can appear in different parts of industry. Probably most relevant is the product portfolio, also influencing the supply chain, raw materials, the number of processes, brands, and packaging. Roughly 20% of the products generate 80% of the value, and probably quite a few products burn more money than they make. Since my focus is on lean manufacturing, I will go into more detail for these groups.

However, don’t forget about other areas causing complexity, including market segments, customer portfolio, technologies and IT systems used, and different organizational structures.

Development and Tooling

Every new product needs to be developed, which will increase the fixed costs. The new product may also need custom tools, which adds even more fixed costs. All of this has to be earned again. On the plus side, cost accounting usually is able to associate most of the development costs with the product, so these costs are usually known.

Every new product needs to be developed, which will increase the fixed costs. The new product may also need custom tools, which adds even more fixed costs. All of this has to be earned again. On the plus side, cost accounting usually is able to associate most of the development costs with the product, so these costs are usually known.

Paperwork

Paperwork is not to be underestimated. For example, a part number in automotive will generate about $50,000 over lifetime for only creating and maintaining the number and associated documentation. This does not include any development or production, only the office paperwork for the part number.

Paperwork is not to be underestimated. For example, a part number in automotive will generate about $50,000 over lifetime for only creating and maintaining the number and associated documentation. This does not include any development or production, only the office paperwork for the part number.

Granted, automotive part numbers are high-maintenance part numbers, but even less demanding manufacturers can easily generate costs of $10,000 per part number over lifetime. That’s all money you have to earn again! The problem is compounded by the fact that a new product usually has more than one new part number. If there are ten new part numbers, this would represent an expense of $100,000 over lifetime just for the paperwork.

Worst of all, in traditional cost accounting, this expense does not really pop up with the part number, but hides the cost in some general overhead categories. The paperwork associated with the product is often not even known.

Raw Material and Finished Goods Inventory

To sell products, you need stocks. You definitely need raw material stocks. Unless you produce exclusively on order, you also need stocks of finished goods. The more you sell of one part number, the less stocks are needed per unit sold for the same delivery performance. In reverse, if you divide your sales on more than one stock-keeping unit, the numbers sold go down per part number and the required stock per unit sold increases – or your delivery performance goes down.

To sell products, you need stocks. You definitely need raw material stocks. Unless you produce exclusively on order, you also need stocks of finished goods. The more you sell of one part number, the less stocks are needed per unit sold for the same delivery performance. In reverse, if you divide your sales on more than one stock-keeping unit, the numbers sold go down per part number and the required stock per unit sold increases – or your delivery performance goes down.

However, inventory is not only waste (muda), but the biggest waste of all the seven types of waste. Excess stocks negatively affect a multitude of other parameters. Inventory is a multiplier of problems. It ties up cash, lead times are longer, quality problems are detected later, quality problems may result from longer storage, material has to be handled, and so on. In sum, significant costs are associated with inventory, only a fraction of which are accounted for in traditional bookkeeping.

If you are out of stock for finished goods, the customer is affected and this leads to lost sales, penalty payments, and a bad reputation, all of which are usually hard to quantify. In that sense, a lack of raw materials affects only your own production, creating chaos on the shop floor due to a switch in production schedule and re-organizing of the manufacturing process.

Training – and Forgetting

To produce new products, your employees have to be trained to produce the new product. The more different products they have to remember, the more likely it is that they will forget something. Hence not only do training costs increase, but also defect costs. Naturally, this training is not only in manufacturing, but also in sales and service. It is embarrassing if the salesperson does not know the product – but unfortunately it happens all too often.

Spare Parts and End-of-Life Ramp Down

Finally, there is a requirement for providing spare parts. In most Western countries, this is usually at least ten years after the stop of production. However, this means you either have to produce small quantities of spare parts for another ten years or keep ten years’ worth of spare part stock. Neither option is desirable. Production in small quantities is very expensive. You need to re-train the workers for the small batch of materials every few months. You need to get small batches of material from your suppliers (if they are still around). You have to dig up and set up the old tools again. Even with the higher prices for spare parts, you probably will not break even if all costs are included.

Putting spare parts in stock for multiple years is sometimes the better option, but still expensive. You probably need whole warehouses for nothing but spare part storage. All these costs happen only at the end of the product life cycle, and hence they are hard to estimate at the beginning, let alone determine when production will end. In any cases, the person starting the development of the back-then new product will be long gone.

Summary

Cost of complexity by introducing new product is a silent killer of revenue. It usually does not show up in bookkeeping very well, but the harm is done regardless of the numbers. Yet in Western industry there is still a trend toward “more is better,” and the product portfolio is more and more segmented to chase even the tiniest sliver of a possible market. Besides, for upper management it usually looks better to introduce new products than to phase out old ones.

Even on the lower levels, this problem is not always understood. I had quite a few complexity reduction projects, where – if everybody would have gotten their way – there would have been more products after reduction than before. I have seen companies where enormous efforts were undertaken and resistance had to be overcome to eliminate two old products with very minor sales, while at the same time twenty new products were introduced at a whim. Manufacturing was collapsing under the complexity, material and finished goods availability was abyssal, total inventory increased, and chaos reigned everywhere.

Don’t make the same mistakes. if you can, eliminate products and reduce the number of new products started. Do it like Jørgen Knudstorp and steer your company toward profitability. Reduce your inventory and improve your industry!

Sources

- A. T. Kearney: How Much Does Complexity Really Cost?, 2007

- Wikipedia: Complexity management