Let’s face it – you have more things to do than you can reasonably do in the available time. A constant stream of tasks or problems are waiting for a lean solution. This two-post series wants to help you with that. In this first post, we will discuss how to avoid work overload using a simple project management board. A second post will tell you how to Manage Your Lean Projects – Prioritize.

Let’s face it – you have more things to do than you can reasonably do in the available time. A constant stream of tasks or problems are waiting for a lean solution. This two-post series wants to help you with that. In this first post, we will discuss how to avoid work overload using a simple project management board. A second post will tell you how to Manage Your Lean Projects – Prioritize.

Prelude – Work Life is Busy

In most industries I know, there are always problems piling up. If your work is related to the shop floor, logistics, or the customer, then the shop floor will provide you with a never-ending stream of issues to be addressed. If you’re somewhat more distant from the shop floor, it is usually your manager or your customer providing a stream of tasks. In western management especially, it is common to simply hand down most problems to someone lower in the hierarchy and let that person sort out what’s important and what’s not. (However, in defense of top management, there are always enough problems left for top management).

In short: You have more work to do than you can do in the available time you have.

Don’t Start Them All!

Facing a large number of tasks, the worst thing you can do is to start them all! Yes, you may be able to start (almost) all the tasks, but you’ll be unable to complete them. Simply managing all the tasks will take so much time that you rarely get anything finished.

For an individual employee, working on two to three topics simultaneously is considered to be the best utilization of his or her time. This, however, does include the daily routine tasks, leaving capacity for only one or two side projects. Anything more will start to clog things up.

For organizations – say a plant or similar entity – there is, of course, more capability. However, these projects probably need a few key people (e.g., a master foreman, an engineer, or a programmer) to make this happen. In this case, they are the bottleneck on the number of projects that a plant can do simultaneously, and the system will get clogged up again.

Analogy: Manufacturing System

In manufacturing, one key concept for a lean manufacturing system is to limit the work in progress. To avoid overloading the system, a new work order is started only if a previous work leaves the system.

In manufacturing, one key concept for a lean manufacturing system is to limit the work in progress. To avoid overloading the system, a new work order is started only if a previous work leaves the system.

The most popular concept in lean manufacturing for this is Kanban, where a new part is produced only if a previous part has left the system. Another possible approach would be a Constant Work in Progress system, better known as CONWIP. The latter has advantages for a high-variety, low-volume mix of production. In any case, the workload in the factory has to be limited; otherwise, work in progress will inflate, costs will increase, and delivery times will suffer.

Limit the Number of Active Projects!

This importance of limiting the number of works in progress also applies to project management. As a manufacturing system starts to clog up with too much work in progress, so will you. Simply managing the projects will take more time than actually advancing projects, and your change process slows down.

This importance of limiting the number of works in progress also applies to project management. As a manufacturing system starts to clog up with too much work in progress, so will you. Simply managing the projects will take more time than actually advancing projects, and your change process slows down.

The solution is the same: Limit the number of projects that are active simultaneously. Start a new project only after a previous one has been completed. This way you will increase the number of projects completed. Even more important, projects are completed much faster.

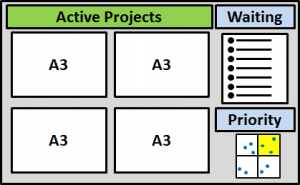

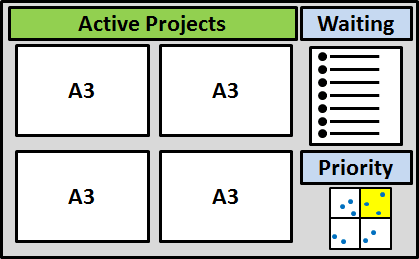

The Project Management Board

An simple way to limit the number of projects that are active simultaneously is a project management board. Limit the space for the number of active projects on the board. In the example below, I have left space only for four projects, each represented by an A3 (a single sheet of paper to keep track of the project status, popular in lean manufacturing). All other projects that pop up are added to a waiting list. Only when a previous project is completed does a new project move into its place. Thus you can both limit and keep track of the number of active projects.

How Many Projects Simultaneously?

So how many projects should you have active simultaneously? It depends. As mentioned above, a single person works best with around two to three active projects (including daily chores). However, in the western world, management is used to higher numbers, and telling your boss that you won’t start a project because you already have two projects going may raise an eyebrow or two. Depending on your boss, you may take on more projects than ideal for the sake of appearance. I don’t like it, but I have been there, too.

As for larger groups, it is also necessary to restrict the number of ongoing projects. For example, if you manage a plant, multiple people will take on different projects. However, the restriction here is the people needed to make the projects work (e.g., the master foreman, engineers, or programmers). Hence I also would not shoot too high, but the details depend heavily on your plant.

Next: Prioritize

Once a project is completed, a new project is selected. In my post next week, I will tell you all about how to prioritize and select a project among many projects.