During my last trip to Japan, I finally took videos capturing the Japanese Pointing-and-Calling standard. Pointing and calling is a safety standard that started with Japanese train operators but now is widely used in industry. The idea is that whenever you confirm something, you not only look at it, but also point at it and call out your observation.

The Technique

Pointing and calling combines looking at something, pointing at it, calling out the observation, and listening to your own voice. For example, when a speed limit starts in 500 meters, the train driver points at the sign and says, “Limit 75 Distance 500.” When leaving the station, the driver points at the timetable and says, “Three o’ clock 12 minutes 15 seconds depart Shibuya station.” The conductor points at the doors after closing and states, “Good Closure,” then points at the monitors and states, “Good monitors for departure.” There are dozens of examples of places where this technique is used. The following video shows a few of them, with different train operators using the pointing-and-calling standard, plus one employee at Toyota headquarters using this standard while crossing the road.

Video of Examples of Pointing and Calling in Japan

The video is available under the Creative Commons Attribution-ShareAlike 3.0 Unported License (CC-BY-SA 3.0), meaning you are free to use the video (including commercial use), as long as you give credit to Christoph Roser on AllAboutLean.com and your resulting product is also licensed as CC-BY-SA 3.0.

In Japanese, these techniques are known by different terms; for example, Shisa kanko (指差喚呼); Shisa kakunin kanko (指差確認喚呼); Yubisashi koshō (指差呼称); and Shisa koshō (指差呼称). In English also sometimes called the “yosh check“, after the Japanese sound (not a proper word) “yoshi” which means something like “all right”.

The Value of Pointing and Calling

Pointing and Calling gives co-action and co-reaction among the operator’s brain, eyes, hands, mouth, and ears. Not only looking but also pointing and sometimes stating the observation avoids sloppiness and helps keep focus and attention. For simple tasks (and most of these tasks are reasonably simple), this technique reduces errors by almost 85%. Some companies use only pointing, or only calling, but the technique is most effective when combined.

Additionally, pointing and calling allows for easy process confirmation. A supervisor observing the employee can easily verify that the signal has been seen and that the timetable has been checked. Hence, it is much easier to train operators and correct mistakes.

Furthermore, this technique reduced accidents at Japanese railway companies by 30%, helping them make train travel in Japan the most reliable and safest train travel in the world (although not necessarily the cheapest).

Examples for Point and Call

With Japanese railroads, anything that has to be looked at is usually confirmed using point and call. First and foremost, this is for observing railroad signals that indicate whether the train is allowed to proceed, whether there are speed restrictions, or whether the train needs to stop.

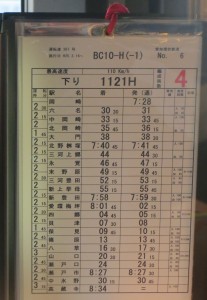

The technique is also used to verify the timetable. At every stop, the driver points to the corresponding line in the timetable to verify the target arrival and departure times. Naturally, the look at the watch also includes pointing at the watch. (By the way, in Japan the internal timetables are by the second!) Furthermore, Japanese train operators are not allowed to carry mobile phones, since texting while driving a train is as dangerous as with texting while driving a car.

When the train stops, the speed is verified by pointing at the speedometer. Platform attendants and conductors also point along the platform to check if the train is clear, often also pointing at additional surveillance monitors for this purpose.

Usage Outside Japanese Railway Companies

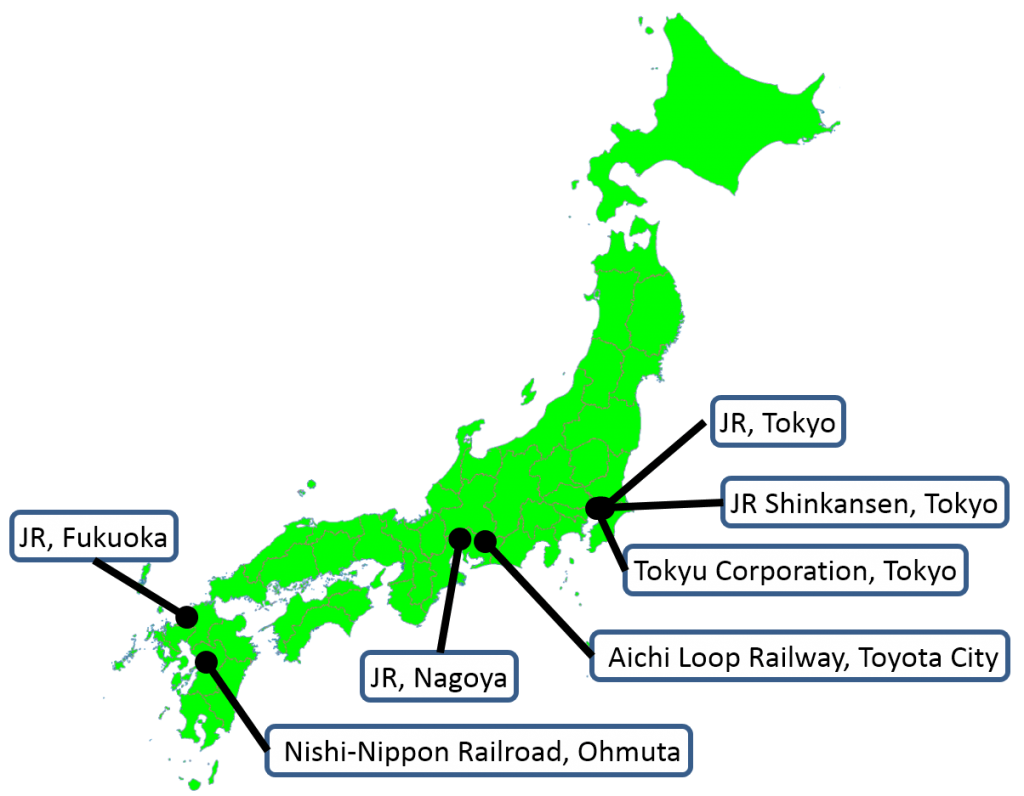

The technique started with Japanese railway companies around 1900, and it is now widespread throughout Japan. Over the years, I have observed dozens of operators of many different railway companies in many different locations. Every time, it has been a beauty to watch this magnificent standard in action.

The standard has also spread outside Japanese railway companies. The Japanese Industrial Safety and Health Association has included this pointing-and-calling standard in its trainings since around 1980, helping the spread of this method.

For example, some companies require their employees to look and point when crossing the road. In my observation, however, there is less diligence here. Only about 5% of the people I observed at Toyota Headquarters followed this standard. Some bus companies in Japan have also introduced this standard.

This standard is also often used in industry for visual confirmation. I have also seen this during the quality check of printed products. The operator points with his finger at every spot he is supposed to check (unfortunately, I was not taking a video of this at the time). Electricians point at the wires they work on and call “Beware of electric shock. Okay!” This standard is also used for inspection of the workplace before maintenance, pointing and calling, “Motor stop. Okay!” When opening or closing valves, the operator points and calls, “Good valve closed” or “Good valve open.” There are many more examples in industry, albeit not all companies use this technique. Some construction companies have also adapted this approach.

The technique is also used in the New York subway system, albeit to a much lesser extent, and on some trains in Korea and Taiwan, and by construction companies in Hong Kong. Other than that, there are very few instances where this standard is used in the rest of the world.

Acceptance Problems

There is one problem with this standard: many people are reluctant to do this. Pointing, or even pointing and calling, may look strange to outsiders. I believe if you ask the average Western employee to point his finger at a sign every time, you may get a completely different finger in your direction (even if only in the operators mind).

Initially, Japanese employees were also reluctant to use this technique, and it took some effort to get over this feeling of embarrassment. Nowadays, however, it is part of everyday life.

Editorial Notes

All operators and employees observed were asked for permission beforehand. There was no difference visible in their use of the standard before and after I indicated my desire to videotape them. The video above is provided via YouTube.

PS: Fellow author and blogger James Albright also covered this topic from a pilots point of view.

Well, there is one honourable exception in the western hemisphere 🙂

https://www.youtube.com/watch?v=i9jIsxQNz0M

And BTW, the Japanese WTT are to the quarter of a minute while the European ones are generally to the half minute (although they do take that quarter of a minute quite seriously indeed)