This post continues the series on the pillars of Total Productive Maintenance (TPM). Here we look at the last four pillars: quality, training, administrative, and safety. However, I find those pillars weaker than the first four. While the topics are important, in my view they should not be separate pillars. I think these topics are either better placed elsewhere (administrative) or should be integral part of all the other pillars (quality, training, and safety). Hence, I believe this is a weaker part of the TPM framework, and I won’t go into as much details as the previous pillars. In any case, let’s have a look. But feel free to disagree! I am looking forward to your comments, as I will surely learn something from them.

This post continues the series on the pillars of Total Productive Maintenance (TPM). Here we look at the last four pillars: quality, training, administrative, and safety. However, I find those pillars weaker than the first four. While the topics are important, in my view they should not be separate pillars. I think these topics are either better placed elsewhere (administrative) or should be integral part of all the other pillars (quality, training, and safety). Hence, I believe this is a weaker part of the TPM framework, and I won’t go into as much details as the previous pillars. In any case, let’s have a look. But feel free to disagree! I am looking forward to your comments, as I will surely learn something from them.

Administration

Reducing Lead Time 4 – Development

Reducing lead time is often important for the success of a company. This last out of four posts looks a bit more in detail at the reduction in lead time during product development. This is especially important for make-to-order production, but also for the introduction of new products into the market. Let’s have a look.

Reducing lead time is often important for the success of a company. This last out of four posts looks a bit more in detail at the reduction in lead time during product development. This is especially important for make-to-order production, but also for the introduction of new products into the market. Let’s have a look.

Lean Is Tough – The Phases of a Lean Transformation

Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

How to Determine Your Lot Size – Part 2

A good lot size has a significant impact on the performance of the system. In this second post, I look at the influence of the machine batch size on the lot size. I also briefly go into the lot sizes for the processing industry, and also administrative processes. In my next and last post I will look at how to manage different lot sizes in different parts of the value stream.

A good lot size has a significant impact on the performance of the system. In this second post, I look at the influence of the machine batch size on the lot size. I also briefly go into the lot sizes for the processing industry, and also administrative processes. In my next and last post I will look at how to manage different lot sizes in different parts of the value stream.

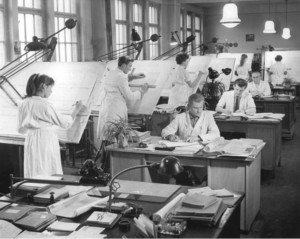

The Challenges of Lean Administration

Lean started with manufacturing, but since then has moved in many other areas of the economy, from lean banking to lean healthcare. One major part of modern economy is administrative processes, which includes things like making offers, procurement, accounting, engineering, research, and many others. By some estimates, more than half of the cost of producing companies are in administration. Up to 80 percent of the lead time is due to administration. A lot of the principles behind lean can be used in administration. However, there are also some unique challenges that are less prominent in manufacturing. Let’s have a look.

Lean started with manufacturing, but since then has moved in many other areas of the economy, from lean banking to lean healthcare. One major part of modern economy is administrative processes, which includes things like making offers, procurement, accounting, engineering, research, and many others. By some estimates, more than half of the cost of producing companies are in administration. Up to 80 percent of the lead time is due to administration. A lot of the principles behind lean can be used in administration. However, there are also some unique challenges that are less prominent in manufacturing. Let’s have a look.