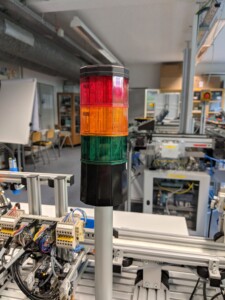

Stack lights are found everywhere in industry. And for a good reason. They are a quick and easy way to visualize the status of a machine, which otherwise would need some effort to see. They are—sort of—a mini-andon. While sometimes underappreciated, they do serve a valuable purpose in the factory, and they usually do a good job. Let’s have a look at stack lights!

Stack lights are found everywhere in industry. And for a good reason. They are a quick and easy way to visualize the status of a machine, which otherwise would need some effort to see. They are—sort of—a mini-andon. While sometimes underappreciated, they do serve a valuable purpose in the factory, and they usually do a good job. Let’s have a look at stack lights!

Visualization

Posts about visualization in lean manufacturing. Actually seeing things (rather than just getting some data sheets) is a key part of lean manufacturing.

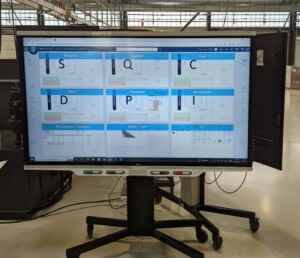

The Difficulties of Dazzling Digital Shop Floor Dashboards

Digital shop floor dashboards are popular nowadays, and are found in many companies. However, they often seem more like a decorative element than a functional way to transfer information. In this blog post, I will look deeper into the possibilities and problem with digital shop floor displays and how to make them work. This blog post was inspired by the Van of Nerds trip through France in 2022, organized by Franck Vermet and Michel Baudin.

Digital shop floor dashboards are popular nowadays, and are found in many companies. However, they often seem more like a decorative element than a functional way to transfer information. In this blog post, I will look deeper into the possibilities and problem with digital shop floor displays and how to make them work. This blog post was inspired by the Van of Nerds trip through France in 2022, organized by Franck Vermet and Michel Baudin.

How to See Visual Management

Yet another hot topic in lean manufacturing is visual management. This can be very helpful in running a shop floor, but when done wrong it can also be quite wasteful and embarrassing. In this post I would like to show you the basic principles of visual management with a few examples. There is more to visual management than merely putting lines on the shop floor.

Yet another hot topic in lean manufacturing is visual management. This can be very helpful in running a shop floor, but when done wrong it can also be quite wasteful and embarrassing. In this post I would like to show you the basic principles of visual management with a few examples. There is more to visual management than merely putting lines on the shop floor.

How to Use an Andon – and How Not To

In my last post, All About Andon, I detailed how the mechanical side of an Andon signaling system works, including Andon cords, buttons, and boards. In the Western world, the mechanical side of an Andon system usually works pretty well. However, in most cases, the usage of the Andon is poor to nonexistent. Hence, in this post I tell you how to actually work with an Andon, and then I will give you a rant why companies so often mess it up!

In my last post, All About Andon, I detailed how the mechanical side of an Andon signaling system works, including Andon cords, buttons, and boards. In the Western world, the mechanical side of an Andon system usually works pretty well. However, in most cases, the usage of the Andon is poor to nonexistent. Hence, in this post I tell you how to actually work with an Andon, and then I will give you a rant why companies so often mess it up!

All About Andon

Andons are systems to alert operators and managers about current problems in manufacturing. The system automates the information flow in case of problems. An Andon system usually consists of the actual Andon, sometimes called an Andon board. Often, additional input and output devices are possible, the most famous being probably the Andon line, a cord that can be pulled to alert others about a problem. In a second post I will talk about How to Use an Andon – and How Not To.

All About Swim Lane Diagrams

In my previous posts I described the details of value stream mapping. However, value stream mapping works only for highly linear material and information flows. Unfortunately, many industry processes, especially in administrative or indirect areas, are all but highly linear. To visualize these processes, a new diagram was developed – the swim lane diagram. In this post I will show you how swim lane diagrams work.

All About Spaghetti Diagrams

A spaghetti diagram is a quick and easy way to track distances of parts and people on the shop floor. The name comes from the result looking like a plate of spaghetti. In this post I will explain the details and give some tips and tricks on how to make a good spaghetti diagram.

Practical Tips for Value Stream Mapping

After discussing when to do value stream maps, the symbols, and the basics of value stream mapping, I want to give some more practical tips for value stream mapping. What tools should you use? Do you use a computer (yuck) or a pen and paper (yup)? I’ll also summarize some generally helpful hints in drawing a value stream.

After discussing when to do value stream maps, the symbols, and the basics of value stream mapping, I want to give some more practical tips for value stream mapping. What tools should you use? Do you use a computer (yuck) or a pen and paper (yup)? I’ll also summarize some generally helpful hints in drawing a value stream.