In my previous posts I went into great detail through all the categories of the Toyota KPI dashboard: safety, quality, productivity, and cost. I also explained the additional section on HR development, albeit this may not really be KPI in the normal sense. However, the dashboard often contains even more: a section with the monthly production plan, a section for the allocation of the operator, and different A3s for improvement. Lets dig deeper:

In my previous posts I went into great detail through all the categories of the Toyota KPI dashboard: safety, quality, productivity, and cost. I also explained the additional section on HR development, albeit this may not really be KPI in the normal sense. However, the dashboard often contains even more: a section with the monthly production plan, a section for the allocation of the operator, and different A3s for improvement. Lets dig deeper:

Shop Floor Management

How to Conduct a Shop Floor Meeting

How to Set Up a Shop Floor Meeting – Part 2

In my second post in this series on shop floor management I will look at more things that go into the team corner besides the tracked KPI. How do you manage your improvement activities? What organizational stuff should go in there? Hopefully this will help you make more successful shop floor meetings. In my next post I will also talk about what should NOT go into a team corner on the shop floor.

In my second post in this series on shop floor management I will look at more things that go into the team corner besides the tracked KPI. How do you manage your improvement activities? What organizational stuff should go in there? Hopefully this will help you make more successful shop floor meetings. In my next post I will also talk about what should NOT go into a team corner on the shop floor.

How to Set Up a Shop Floor Meeting – Part 1

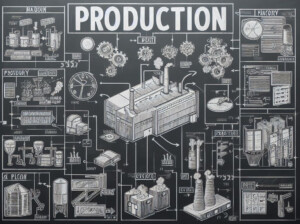

Regular meetings are necessary to keep yourself and others informed. This is also true for the shop floor. Many factories have set up meeting corners for the workers and their supervisors to meet. In this series of posts I would like to show you what you need for a successful shop floor meeting. This first post looks at the hardware and content of the team corner where the shop floor meeting usually happens, as well as the most important KPI that should be addressed in the team meeting.

Regular meetings are necessary to keep yourself and others informed. This is also true for the shop floor. Many factories have set up meeting corners for the workers and their supervisors to meet. In this series of posts I would like to show you what you need for a successful shop floor meeting. This first post looks at the hardware and content of the team corner where the shop floor meeting usually happens, as well as the most important KPI that should be addressed in the team meeting.