The second BMW plant I visited was in Leipzig. This modern greenfield plant had a very good material flow, where especially the finger line impressed me a lot. In terms of efficiency it was the best-performing plant in Germany, shortly after Munich, and on par with Toyota. It was also exceptionally clean. The only flaw I saw was that they have the order to never stop the line… which goes against my lean philosophy. But read on.

Disclaimer: The following are based on my personal observations and opinions and may not be accurate or correct. It is based on publicly available information and what I observed during public tours, and when I observed it. The observations may differ at a different time and place.

BMW Leipzig

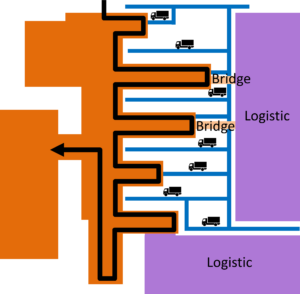

The BMW Leipzig plant did not have the space restrictions of Munich, and was built on a green field. The plant was opened in 2005, and is one of the newest in the BMW group. This gives much more flexibility with the material flow, and the material flow alignment is truly outstanding in Leipzig. They use a highly flexible “finger system” for their final assembly line, which I liked so much that I wrote a separate blog post on this. This allows 80% of the material to be just in time (JIT) and just in sequence (JIS).

I also liked their central building designed by Zaha Hadid, where the car bodies flow right through the offices. Even as an office drone, you will never forget what the whole plant is about. I liked the highly fancy architecture. All offices are open space, including the office of the plant manager.

Similar to Munich, around 9000 workers produce around 1000 cars per day, including 180 electric cars. They do want to increase the volume to 130 cars, though. Like many other car plants, of the 9000 workers, only 5600 are BMW employees; others are subcontractors or temp workers.

One tidbit: They use old batteries from their hybrid vehicles to power their AGVs, and even more of these batteries to buffer the electricity from their four wind turbines. They also have different AGVs, and the latest one, a smaller one from iw.hub, no longer needs induction loops or QR codes but can navigate freely in the plant. It is smart enough to drive around obstacles by itself. I have seen this in the Centre Innovation Évry research lab, but it is rare to see it in production. Other, larger AGVs from ds automation still need induction loops, though.

Press Shop

They have four press lanes where 450 people work in three shifts, albeit three of the lanes were stopped when we visited. All presses were electric, not hydraulic. 70% of the demand from the Leipzig body shop comes from their own press shop. Like Munich, the press shop can switch their very heavy tools extremely fast and be fully automated within three minutes. This is among the fastest I have seen in Germany, and comparable to Toyota.

They are also good with inventory, and I felt like they have small lot sizes compared to other car makers. They claim that they have at most two days worth of inventory. They are also experimenting with robots for picking up the pressed sheet metal at the end and to put in into the storage rack, but the challenge is the optical quality control, which is still better done by human eyes.

Body Shop

BMW Leipzig also had a very high level of 99% automation using 1400 robots to add in average 5300 spot welds. The 650 employees are mostly for maintenance, programming, and generally to keep the robots running. Only four people still add value in the press shop and insert plastic tubes for drainage in the car body. Such floppy parts are hard to automate. The robots also have automatic tool changes.

Interestingly enough, all car bodies are designed both for right hand and left hand driving, and have an opening for the steering column on either side. Only during assembly will the steering wheel be put on one side.

We also visited the light tunnel for the quality control after the body shop and before the paint shop. Here, too, they continue to improve. Side by side was an older light tunnel line, and four light cells. In the old tunnel, the problem was that quality control is unpredictable, and sometimes a problem may slow down a car body for quite some time, blocking all other stations. Since you cannot predict that, you can’t really do mixed model (or workload) sequencing. This made the light tunnel to a constant bottleneck. While I am usually in favor of lines, in this case a cell makes more sense. The four quality control cells had a much higher and more consistent output than the light tunnel lane.

They also adjusted the light. The old tunnel simulated full daylight at noon, which is good for quality but draining for the workers. The newer cells use 15:00 PM Daylight, which is much better for the biorhythm of the workers. In any case, they want to automate this within the next five to six years.

The body shop lead time is 10 hours out of the total lead time for the plant of 32 to 34 hours. This is faster than an industry average of around 40 hours. If a robot breaks down, they have both wheeled and fixed cranes to swap out the problematic robot quickly to continue production.

Paint Shop

The paint shop has 700 employees and 144 robots adding 9kg of paint per car with a lead time of 12 hours. Like Munich they do the two color layers wet-on-wet without drying in between. We did not go to the painting line itself like in Munich, but we visited the light tunnels after the paint shop. Here they use three tunnels plus additional quality control boxes. The light changes slightly according to the color of the (now painted) car to make inspection easier.

Like Munich, cars with a different color roof go through the line twice. However, they are experimenting with what they call “zero over-spray,” where they can spray a color right next to another color without any masking tape. Not sure how that works, but it is at a trial stage. They also look into the possibility to modify the phosphate bath, where the car body takes a full dip before being painted. Currently, the bath runs at 60°, but they hope to lower the temperature to 20° and hence save a lot of energy.

Final Assembly

The 3.4 km long final assembly runs at a quite fast takt of 58 seconds per car, making around 1000 cars per day with 2000 employees at 376 stations. They work in groups of 4 to 20 workers, in two shifts. Like all automotive assembly line, it is mostly manual work, with only 6% of the work done by machines. Like Munich, all cars go through a single assembly line, in this case the BMW 1, the BMW 2 grand coupe and active tourer (hybrid), and the Mini Countryman (also electric). The lead time is 10 hours. This line uses the quite smart Finger Line ssystem.

I was again impressed by how clean the BMW automotive plants are. Only Porsche comes close. It had also the best estimate of the percentage of the time the worker adds value of any plant in Germany with 64%, similar to what I would expect to see at Toyota. One aspect the guide pointed out was that they heat all their cable harnesses to 35°C before assembly for a consistent quality.

I liked the plant a lot, except one (in my opinion) flaw: Their line must always run. They don’t stop the line. They do have andon cords in two colors, which before actually could slow (blue) or stop (yellow) the line, but now both merely call for help. If the car has a problem that cannot be fixed within the station, it gets removed from the line and added later again after fixing. While this does improve the output of the line somewhat, it totally takes the pressure off from actually fixing the problem. Hence, I am a bit uncertain if this is actually a good thing, and would be hesitant to copy that. My next post will look at the third BMW plant I visited in Berlin, making motor bikes. Now, go out, stop your line in case of problems and organize your industry.

If You Want to Follow in My Footsteps

BMW offers tours to the general public in Munich, Leipzig, and Berlin (their motorbike plant). For Munch you can reserve tickets here. This two-hour tour was the only one of the many tours in Germany where we actually went into the paint shop. Both tours in Munich and Leipzig were very good and the guides were very informative. You also see some fancy architecture.

PS: Many thanks to BMW for offering tours through their plants to the public!

Thanks for sharing your personal insights, Christoph! As a fellow BMW enthusiast, it’s always exciting to dive into the intricacies of automotive manufacturing, especially when it involves our favorite brand.

Looking forward to more of your BMW adventures, and let’s keep the spirit of innovation and excellence alive in the automotive world!

Hi Chris, Any way to obtain copy of your Toyota series?

Thanks,

Harry

Hi Harry, this is the The Grand Tour of Japanese Automotive, a series of 8 blog post. The first one is here.