Pull production is a highly useful tool in manufacturing, logistics, services, and other industries. However, there are instances where pull may be not the best option. These instances are rare, but they do exist. In this blog post I will list different cases when pull may not be the best option.

Pull production is a highly useful tool in manufacturing, logistics, services, and other industries. However, there are instances where pull may be not the best option. These instances are rare, but they do exist. In this blog post I will list different cases when pull may not be the best option.

Information Flow

How to Deal With Long Delivery Times

Lean has a bunch of advanced but good tools for material delivery, like Just in Time, Just in Sequence, and Ship to Line. Using them is much easier on short distances and with short delivery times. Yet, sometimes you just don’t have the option of short delivery times. This blog post deals with the issues related to long lead times and delivery times.

Lean has a bunch of advanced but good tools for material delivery, like Just in Time, Just in Sequence, and Ship to Line. Using them is much easier on short distances and with short delivery times. Yet, sometimes you just don’t have the option of short delivery times. This blog post deals with the issues related to long lead times and delivery times.

Different Ways to Establish a Pull System – Part 2

This is the second post on different types of pull production. It features the less commonly known approaches of triangle kanban, drum-buffer-rope, reorder point (surprise, yes, it is a pull system), reorder period (also a pull system), and FIFO lanes. In my previous post I showed you the kanban system and its variant, the two-bin system, as well as CONWIP and the kanban-CONWIP hybrid.

This is the second post on different types of pull production. It features the less commonly known approaches of triangle kanban, drum-buffer-rope, reorder point (surprise, yes, it is a pull system), reorder period (also a pull system), and FIFO lanes. In my previous post I showed you the kanban system and its variant, the two-bin system, as well as CONWIP and the kanban-CONWIP hybrid.

Different Ways to Establish a Pull System – Part 1

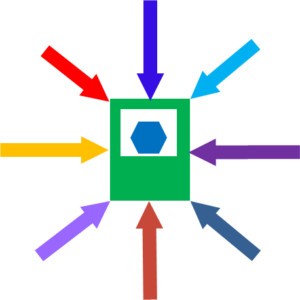

Pull production is one of the most important aspects of lean production. Its key feature is to have an upper limit on inventory that is not to be exceeded. The most well-known way to implement a pull system is by using kanban cards. However, there are many others. In this short series of two posts, I want to give you an overview of the different ways to implement pull systems, and discuss the pros and cons of them.

Pull production is one of the most important aspects of lean production. Its key feature is to have an upper limit on inventory that is not to be exceeded. The most well-known way to implement a pull system is by using kanban cards. However, there are many others. In this short series of two posts, I want to give you an overview of the different ways to implement pull systems, and discuss the pros and cons of them.

Organize Your Production Sequence – 3: Flow Shop

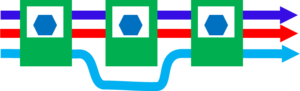

The flow shop is usually preferred for most lean production systems. In a flow shop, the processes are arranged in the sequence of the production steps. If you can manage to establish a flow shop, your production will be much more efficient than in a job shop or a project shop. In this post I want to talk in more detail about the flow shop. Be warned, this will be a bit of an ode to the flow shop 🙂 .

The flow shop is usually preferred for most lean production systems. In a flow shop, the processes are arranged in the sequence of the production steps. If you can manage to establish a flow shop, your production will be much more efficient than in a job shop or a project shop. In this post I want to talk in more detail about the flow shop. Be warned, this will be a bit of an ode to the flow shop 🙂 .

Organize Your Production Sequence – 2: Job Shop

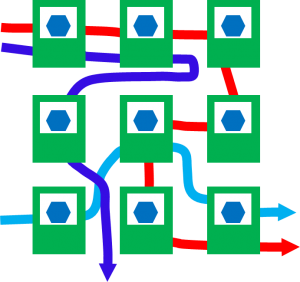

Job shops are a manufacturing system where the machines are not arranged in the sequence of the work steps (as in a flow line). Rather, the flow of the part conforms to the arrangement of the machines.

Job shops are a manufacturing system where the machines are not arranged in the sequence of the work steps (as in a flow line). Rather, the flow of the part conforms to the arrangement of the machines.

This post looks in more detail at the job shop, its advantages and disadvantages, and where it may be useful.

Organize Your Production Sequence – 1: Project Shop

There are different ways to organize your shop floor. You surely know the flow shop and the job shop. There is also a project shop (with many variants of names). While the flow shop is in many cases the ultimate goal, each shop has advantages and disadvantages. Let’s look at them in more detail, starting with the project shop.

There are different ways to organize your shop floor. You surely know the flow shop and the job shop. There is also a project shop (with many variants of names). While the flow shop is in many cases the ultimate goal, each shop has advantages and disadvantages. Let’s look at them in more detail, starting with the project shop.

How to Determine Your Lot Size – Part 3

This is the third and final post on lot sizes (Part 1 and Part 2). After considering all the factors of the processes and inventories (changeover time, batch size, customer order size, and container and shipment size), we now look at how to set up the information flow. This is especially important if we want to have different lot sizes in different sections of our value stream.

This is the third and final post on lot sizes (Part 1 and Part 2). After considering all the factors of the processes and inventories (changeover time, batch size, customer order size, and container and shipment size), we now look at how to set up the information flow. This is especially important if we want to have different lot sizes in different sections of our value stream.