Assembly lines are THE way to do mass production. Yet, with constant regularity people try out to undo the assembly line, only to fail in their endeavor. In my previous post I looked at examples by Volkswagen in Salzgitter, Volvo in Kalmar, and Opel in Bochum, who all tried, just to switch back to an assembly line afterwards. This second post in this series has more historical examples of when people tried and failed to undo assembly lines in mass production.

Assembly lines are THE way to do mass production. Yet, with constant regularity people try out to undo the assembly line, only to fail in their endeavor. In my previous post I looked at examples by Volkswagen in Salzgitter, Volvo in Kalmar, and Opel in Bochum, who all tried, just to switch back to an assembly line afterwards. This second post in this series has more historical examples of when people tried and failed to undo assembly lines in mass production.

History

All postst related to the history of lean, management, manufacturing, and any other topic covered in this blog.

A Frequent Mistake—Undoing an Assembly Line—Part 1

Assembly lines are everywhere in mass production. From mobile phones to cars to airplanes, almost all items produced in large quantities come from an assembly line. Just look around you wherever you are and try to find a produced item that did NOT come from an assembly line. My general recommendation is that if you can make it on an assembly line, then you probably should make it on an assembly line.

However, assembly lines are not always loved by the workers. Every few years, another—usually European—car maker is in the news about undoing the assembly line in favor of group work, box assembly, assembly stations, and the like. So far, all of these initiatives have dwindled and died, simply because the assembly line is the best! Let’s have a look at the long list of car companies that tried and failed with undoing the assembly line. The assembly line is still king in manufacturing!

Training Within Industry—Second-Line Supervisor Job Instructions

Training Within Industry and its modules Job Instructions, Job Relations, and Job Methods are well known. But (thanks to Mark Warren) I just recently learned about another module: Job Instructions for Second-Line Supervisors (nowadays called managers). This is a hierarchy level higher, and the goal is to support and guide the shop floor supervisors on how to use job instructions. Let me dig deeper:

Training Within Industry and its modules Job Instructions, Job Relations, and Job Methods are well known. But (thanks to Mark Warren) I just recently learned about another module: Job Instructions for Second-Line Supervisors (nowadays called managers). This is a hierarchy level higher, and the goal is to support and guide the shop floor supervisors on how to use job instructions. Let me dig deeper:

The Difference between the Toyota Production System and Lean Manufacturing

The Toyota Production System (TPS) is the archetype of lean manufacturing. Lean is often used as a synonym for the Toyota Production System, and that is generally quite accurate. It is also sometimes referred to as the “Westernized” version of the Toyota Production System. However, there are some smaller differences in the underlying approach, as well as some larger and often unintentional differences in its application. Let’s have a look!

The Toyota Production System (TPS) is the archetype of lean manufacturing. Lean is often used as a synonym for the Toyota Production System, and that is generally quite accurate. It is also sometimes referred to as the “Westernized” version of the Toyota Production System. However, there are some smaller differences in the underlying approach, as well as some larger and often unintentional differences in its application. Let’s have a look!

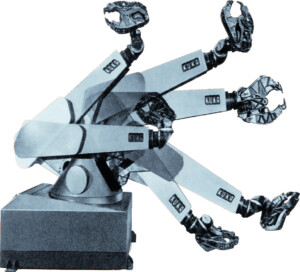

KUKA FAMULUS Turns 50—The First Modern Industrial Robot

Akio Toyoda Steps Down as Toyota CEO

Somewhat surprising to industry insiders, the CEO of Toyota Motor, Akio Toyoda, announced on January 26 his resignation, and he will step down as CEO on April 1, 2023, to become the chairman of the board. Hence, I will have a look at his impact on Toyota. However, just to be warned, if you expect glowing praise, you should look elsewhere. I believe he changed Toyota, a company I love, in a worrisome way. I am definitely not a fan of his work. Granted, being a CEO is not easy, and he did have to lead Toyota through a couple of crises (Recall,s Corona, etc.). Compared to other CEO’s, he is probably somewhere around average. But I believe he had a negative influence on the Toyota corporate culture.

Somewhat surprising to industry insiders, the CEO of Toyota Motor, Akio Toyoda, announced on January 26 his resignation, and he will step down as CEO on April 1, 2023, to become the chairman of the board. Hence, I will have a look at his impact on Toyota. However, just to be warned, if you expect glowing praise, you should look elsewhere. I believe he changed Toyota, a company I love, in a worrisome way. I am definitely not a fan of his work. Granted, being a CEO is not easy, and he did have to lead Toyota through a couple of crises (Recall,s Corona, etc.). Compared to other CEO’s, he is probably somewhere around average. But I believe he had a negative influence on the Toyota corporate culture.

The Impact of ChatGPT on the Future of Work

You may have heard of ChatGPT, the latest buzz in artificial intelligence. ChatGPT is a chatbot by OpenAI that can answer your questions and hold a conversation. And, it is very good at this. It can handle almost anything connected with text. This tool (and the many others that are likely to follow) has the ability to fundamentally change how we work. Let me show you.

You may have heard of ChatGPT, the latest buzz in artificial intelligence. ChatGPT is a chatbot by OpenAI that can answer your questions and hold a conversation. And, it is very good at this. It can handle almost anything connected with text. This tool (and the many others that are likely to follow) has the ability to fundamentally change how we work. Let me show you.

250 Years of the Cromford Cotton Mill – Start of the Industrial Revolution

The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.

The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.