In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

Kanban

Real vs. Planned Data in Pull Systems

Pull systems like kanban and reorder point are a cornerstone of inventory management and fluctuation reduction in lean manufacturing. The production is managed based on ACTUAL consumption. Theoretically, it is also possible to include expected but not yet actual consumption. In this post, I will explain to you the concept behind it and why I think it is a bad idea…

Pull systems like kanban and reorder point are a cornerstone of inventory management and fluctuation reduction in lean manufacturing. The production is managed based on ACTUAL consumption. Theoretically, it is also possible to include expected but not yet actual consumption. In this post, I will explain to you the concept behind it and why I think it is a bad idea…

How Much to Adjust the Pull Inventory Limit

In my last post I looked at the behavior of the supermarket inventory for different kanban systems. In this post I will use this information to estimate how much the material availability of a system changes if you increase or decrease the inventory limit of your pull system (i.e., number of kanban).

In my last post I looked at the behavior of the supermarket inventory for different kanban systems. In this post I will use this information to estimate how much the material availability of a system changes if you increase or decrease the inventory limit of your pull system (i.e., number of kanban).

Parts of this blog post are loosely based on chapter 13.2 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production.

Behavior of a Kanban Supermarket

Setting up a kanban system is tricky, especially determining the number of kanban. The kanban formula is at best a rough estimate. It is usually advisable to adjust the number of kanban as the system is running. In general, if you have too much inventory, reduce the number of kanban. If you run out of material – and the cause is a lack of kanban – then increase the number of kanban. However, this general recommendation can be refined a bit by looking at the supermarket inventory. Let me show you how to improve your kanban system by analyzing your supermarket inventory.

Setting up a kanban system is tricky, especially determining the number of kanban. The kanban formula is at best a rough estimate. It is usually advisable to adjust the number of kanban as the system is running. In general, if you have too much inventory, reduce the number of kanban. If you run out of material – and the cause is a lack of kanban – then increase the number of kanban. However, this general recommendation can be refined a bit by looking at the supermarket inventory. Let me show you how to improve your kanban system by analyzing your supermarket inventory.

This blog post is loosely based on chapter 13.2 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production.

What Different Pull Systems Can Be Combined?

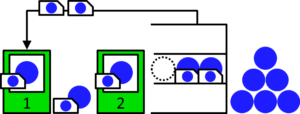

In my last few posts I have shown you different ways to establish pull systems, and which one is right for you. This post discusses how you can mix and combine these systems. You can combine some pull systems within the same pull loop, although there are some restrictions. Combinations of different kanban systems are very common, often also including a CONWIP system.

In my last few posts I have shown you different ways to establish pull systems, and which one is right for you. This post discusses how you can mix and combine these systems. You can combine some pull systems within the same pull loop, although there are some restrictions. Combinations of different kanban systems are very common, often also including a CONWIP system.

You can also combine different pull systems for sequential loop, where for example a kanban system feeds into a CONWIP system. This blog post is loosely based on chapter 3.3 and 11.1.7 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production.

This is a cross post with the same article on Planet Lean.

Which Pull System Is Right for You?

In my last few posts I showed you different types of pull systems, and an overview of the criteria on how to decide which one is right or you. In this post I finally give you a hands-on guide to decide which pull system to use. This blog post is loosely based on chapter 3.2 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. Let’s have a look:

In my last few posts I showed you different types of pull systems, and an overview of the criteria on how to decide which one is right or you. In this post I finally give you a hands-on guide to decide which pull system to use. This blog post is loosely based on chapter 3.2 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. Let’s have a look:

This is a cross post with the same article on Planet Lean.

What Are the Criteria to Decide on a Pull System?

There are different ways to establish a pull system. In my last post I gave an overview of the different types of pull system. Before telling you which one to use when I want to show you the different factors that should go into your decision. What do you have to pay attention to if you want to select a pull system? This post is loosely based on chapter 3.1 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. Let’s have a look:

There are different ways to establish a pull system. In my last post I gave an overview of the different types of pull system. Before telling you which one to use when I want to show you the different factors that should go into your decision. What do you have to pay attention to if you want to select a pull system? This post is loosely based on chapter 3.1 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. Let’s have a look:

This is also a cross-post with the same article on Planet Lean.

The Different Ways to Establish Pull Production

Kanban is the best known way to establish pull production. But it is not the only way. There are many different methods to create a pull system. This blog post is loosely based on my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production, which is a practical guide for anyone looking to implement pull systems. Let me give you an overview.

Kanban is the best known way to establish pull production. But it is not the only way. There are many different methods to create a pull system. This blog post is loosely based on my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production, which is a practical guide for anyone looking to implement pull systems. Let me give you an overview.

This is a Cross-Post with the (almost) identical article 7 tools to establish pull production on Planet Lean.