In 2017-18, I had the chance to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive. In the last few weeks, I had the chance to repeat this for Germany and do a Grand Tour of German Automotive. Let me show you what I saw and what I learned from visiting fifteen vehicle assembly plants all over Germany!

In 2017-18, I had the chance to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive. In the last few weeks, I had the chance to repeat this for Germany and do a Grand Tour of German Automotive. Let me show you what I saw and what I learned from visiting fifteen vehicle assembly plants all over Germany!

Disclaimer: The following are based on my personal observations and opinions and may not be accurate or correct. It is based on publicly available information and what I observed during public tours, and when I observed it, and the observations may differ at a different time and place.

Overview

There are around twenty automotive final assembly plants in Germany. During my different visits criss-crossing all over Germany, I was able to visit thirteen of twenty German automotive final assembly lines. And, while I was at it, I also visited a motorbike plant (BMW Berlin) and the largest heavy-duty truck plant in the world (Mercedes Benz in Wörth). Overall, I spent over 6000 km on the road.

I have seen Volkswagen in Wolfsburg, Osnabrück, Emden, and Dresden… albeit the transparent factory of VW in Dresden is a somewhat unique plant and cannot really be compared with other “normal” automotive plants. Hence, I will talk about VW Dresden only at the very end of this (admittedly rather long) blog post series.

Another brand that belongs to the VW group is Porsche, where I visited both their headquarters in Zuffenhausen and their new plant in Leipzig. I also saw their Porsche line in the Volkswagen Osnabrück plant. Audi is also part of the VW group, and I went to their main plant in Ingolstadt and their second plant in Neckarsulm.

In 2022, Daimler split off their truck business and renamed iteself Mercedes Benz. I visited both of their plants in Sindelfingen, Rastatt, and Bremen, as well as the Daimler Truck plant in Wörth. While technically now a separate company, I grouped it under the same brand.

Finally, I visited BMW in Munich and in Leipzig. From the point of view of lean manufacturing, BMW is in my view the most advanced car maker, and miles ahead of the competition. Their performance is comparable to Toyota, and they are the only plants where I had a “Toyota feeling” when observing the production line. Some selected Porsche lines also stand out, but BMW is clearly the top performer in Germany… at least for their Munich and Leipzig plants. I also visited their plant in Berlin where they make motor bikes, but… this was very different and a far cry from the outstanding organization of BMW in Munich and Leipzig. On a side note, the BMW Leipzig plant designed by Zaha Hadid is also the prettiest plant to look at. The buffer for car bodies runs right through the offices.

So, overall, I have seen two-thirds of all car final assembly plants in Germany. I did not visit engine plants, component plants, battery plants, and other supplier plants, but I have a pretty decent overview of the car final assembly plants.

However, I have not (yet) seen them all. I haven’t been to VW Hannover where they make commercial trucks, and Audi/VW in Zwickau where they make the Golf and the Passat. However, there is a possibility that I may see Zwickau in September.

For Daimler I have not yet been to their light-duty vehicles plant in Ludwigsfelde, near Berlin and Düsseldorf. I would also love to see BMW in Dingolfing and Regensburg, as I do have high expectations of their production system.

Ford also has two plants in Germany, but Saarlouis will be closed, and Cologne is currently under reorganization for the new all-electric Ford Explorer. Tours will be possible in the summer again, and maybe I can make a visit there too!

And finally, there is Tesla in Berlin, which I would also have loved to see. However, at the moment it is nearly impossible to get into the Tesla plant, and even journalists can’t get in. The only visits I have heard of were for long-established and respected members of the German Tesla fan club… which I am not.

Efficiency

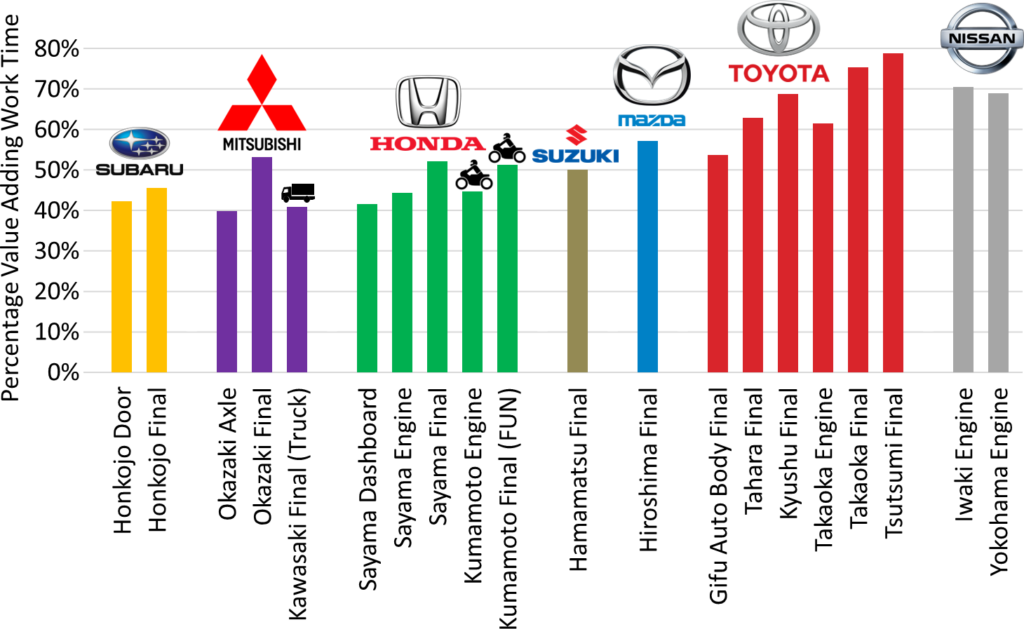

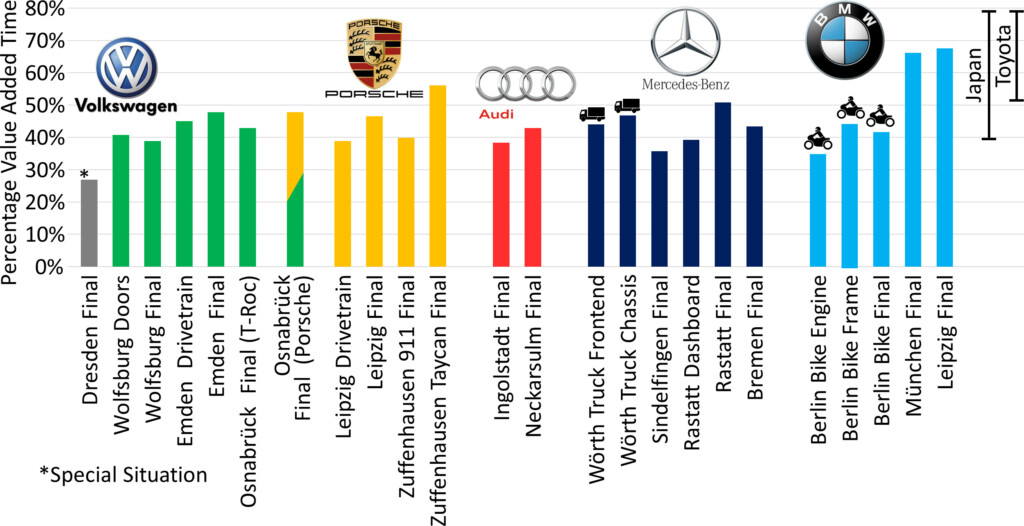

As always, I love to estimate the percentage of the time that the workers add value to the product, rather than searching, waiting, walking, transporting, and all the other seven types of waste. Below is my estimate based on what I saw during my visit.

For reference, here is the data from the Grand Tour of Japanese Automotive in 2017/18.

As mentioned above, BMW in Munich and in Leipzig definitely stand above the rest of Germany and approach a performance comparable to Toyota. These are definitely the best car plants you can find in Germany. Their BMW bike plant in Berlin… not so much. Berlin especially lacks in the maintenance and organizational department.

The Taycan final assembly line of Porsche was also rather good. This is their latest and newest line, established in 2020. Their twenty-year-old line in Leipzig is also decent, and their forty-year-old line for the 911 in Zuffenhausen is merely average. A former Porsche manager is currently CEO of the Volkswagen group, and there is the hope or expectation that he will improve the situation for the rest of the VW group, which is overall a bit mixed.

And, oh, Dresden is a special case. The transparent manufactory was built to impress people (back then for the luxury Phaeton), and it does indeed impress… albeit not in terms of efficiency. Since it is more of a showcase manufactory than a for-profit plant, their performance is abysmal, and it is the bottom of the barrel of German car manufacturing in terms of value for money. But again, its goal is to impress customers rather than to build cars efficiently. And it does impress. However, this is a rather costly museum manufactory, and there are rumors that cash-strapped Volkswagen will pull the plug and close the plant.

Daimler, or Mercedes, is also mixed. I liked their Rastatt plant quite a bit. I was also surprised how well the Daimler truck plant in Wörth was performing. It is even better than the Mitsubishi Kawasaki truck plant in Yokohama… albeit that is now also Daimler Trucks Asia.

In this series of sixteen blog posts (which may be my longest series so far), I will visit each plant with you, introduce their strengths and weaknesses, and tell you what I found interesting, odd, good, unusual, or sometimes even outright strange. In my next post, I will start with the company that has impressed me the most, BMW. Now, go out, join me on my tour through Germany, and organize your industry!

PS: Many thanks to all the car makers for offering tours through their plants to the public!

Hello there, do you have any thoughts on the size of German factory complexes as compared to Japanese ones? Some of these German factories like Vw Wolfsburg or Mercedes Sindelfingen are one of the largest in the world.

Thanks