Assembly lines are THE way to do mass production. Yet, with constant regularity people try out to undo the assembly line, only to fail in their endeavor. In my previous post I looked at examples by Volkswagen in Salzgitter, Volvo in Kalmar, and Opel in Bochum, who all tried, just to switch back to an assembly line afterwards. This second post in this series has more historical examples of when people tried and failed to undo assembly lines in mass production.

Assembly lines are THE way to do mass production. Yet, with constant regularity people try out to undo the assembly line, only to fail in their endeavor. In my previous post I looked at examples by Volkswagen in Salzgitter, Volvo in Kalmar, and Opel in Bochum, who all tried, just to switch back to an assembly line afterwards. This second post in this series has more historical examples of when people tried and failed to undo assembly lines in mass production.

History

A Frequent Mistake—Undoing an Assembly Line—Part 1

Assembly lines are everywhere in mass production. From mobile phones to cars to airplanes, almost all items produced in large quantities come from an assembly line. Just look around you wherever you are and try to find a produced item that did NOT come from an assembly line. My general recommendation is that if you can make it on an assembly line, then you probably should make it on an assembly line.

However, assembly lines are not always loved by the workers. Every few years, another—usually European—car maker is in the news about undoing the assembly line in favor of group work, box assembly, assembly stations, and the like. So far, all of these initiatives have dwindled and died, simply because the assembly line is the best! Let’s have a look at the long list of car companies that tried and failed with undoing the assembly line. The assembly line is still king in manufacturing!

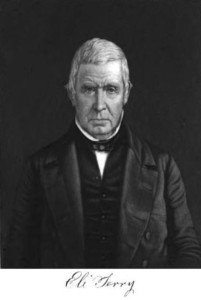

250 Years after the Birth of Eli Terry

Two hundred fifty years ago today, clockmaker Eli Terry was born on April 13, 1772 in (what is now) South Windsor, Connecticut, USA. He was one of the earliest industrialists using mass production with interchangeable parts in the USA, contemporary with the better-known muskets of Honoré Blanc in France (ca. 1785), and long before John Hancock Hall at the Harpers Ferry Armory (ca. 1824). His name is known mostly to nerds in manufacturing and horology, but I believe his achievements deserve recognition. Hence I will go back in history to look at his life.

Two hundred fifty years ago today, clockmaker Eli Terry was born on April 13, 1772 in (what is now) South Windsor, Connecticut, USA. He was one of the earliest industrialists using mass production with interchangeable parts in the USA, contemporary with the better-known muskets of Honoré Blanc in France (ca. 1785), and long before John Hancock Hall at the Harpers Ferry Armory (ca. 1824). His name is known mostly to nerds in manufacturing and horology, but I believe his achievements deserve recognition. Hence I will go back in history to look at his life.

50 Years after the Death of Lillian Evelyn Gilbreth

Fifty years ago today, Lillian Evelyn Gilbreth (May 24, 1878 – January 2, 1972) passed away. She was an early pioneer in optimizing and streamlining work, which is especially remarkable in a time when women were supposed to be at home in the kitchen instead of pursuing science and engineering. I already wrote briefly about her, her husband, and Frederick Winslow Taylor in my post The Tale of Taylor and Gilbreth. I also have her portrait, among other key people in the history of manufacturing, hanging in my office. Let’s have a look at the life of this very remarkable and outstanding woman!

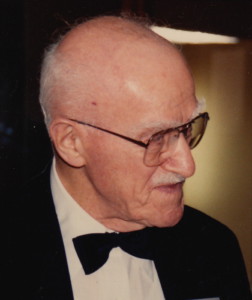

115 Years after the Birth of Joseph Juran

On Christmas Eve 115 years ago, Joseph Moses Juran (December 24, 1904 – February 28, 2008) was born. He was a highly respected and very influential quality guru. His work not only helped the United States, but also changed Japan, possibly even more than that of his better-known colleague Edwards Deming. Time to look back on his life’s impact on the world.

On Christmas Eve 115 years ago, Joseph Moses Juran (December 24, 1904 – February 28, 2008) was born. He was a highly respected and very influential quality guru. His work not only helped the United States, but also changed Japan, possibly even more than that of his better-known colleague Edwards Deming. Time to look back on his life’s impact on the world.

150 Years after the Birth of Albert Kahn

Albert Kahn (1869–1942) is an often unknown but very influential figure in the history of manufacturing. An architect by trade, he revolutionized industrial architecture, and is often nicknamed the “Architect of Detroit.” Most modern factories have a design that goes back to his innovations. Since he was born exactly 150 years ago on March 21, 1869, it is a good time to look at his achievements.

Albert Kahn (1869–1942) is an often unknown but very influential figure in the history of manufacturing. An architect by trade, he revolutionized industrial architecture, and is often nicknamed the “Architect of Detroit.” Most modern factories have a design that goes back to his innovations. Since he was born exactly 150 years ago on March 21, 1869, it is a good time to look at his achievements.

Hoshin Kanri and the Kanri Noryoku Program: Rejuvenating Toyota

How Cheap Can You Make it?

I was on a quest, a quest to find the cheapest ballpoint pen possible. And what I found was amazing. Modern manufacturing has achieved stunning productivity, where even a complex product like a ballpoint pen can be produced at costs that were unbelievable only a few decades ago. While everybody can make a pen, the goal in manufacturing is always to make it cheaper! For the same functionality, the customer will almost always go for the cheaper products. Let me show you the results of my quest.

I was on a quest, a quest to find the cheapest ballpoint pen possible. And what I found was amazing. Modern manufacturing has achieved stunning productivity, where even a complex product like a ballpoint pen can be produced at costs that were unbelievable only a few decades ago. While everybody can make a pen, the goal in manufacturing is always to make it cheaper! For the same functionality, the customer will almost always go for the cheaper products. Let me show you the results of my quest.