Good problem solving can seriously help you with the performance in your plant. John Shook recently pointed out another nice example to me: the Japanese Men’s 4x100m relay team during the 2016 Olympics in Rio. They were the underdogs, with none of their team having ever run 100m in under 10 seconds. Yet they stunningly won the silver medal! They achieved this through good problem solving. Let me show you the details:

Good problem solving can seriously help you with the performance in your plant. John Shook recently pointed out another nice example to me: the Japanese Men’s 4x100m relay team during the 2016 Olympics in Rio. They were the underdogs, with none of their team having ever run 100m in under 10 seconds. Yet they stunningly won the silver medal! They achieved this through good problem solving. Let me show you the details:

Analysis

The Many Flavors of the PDCA

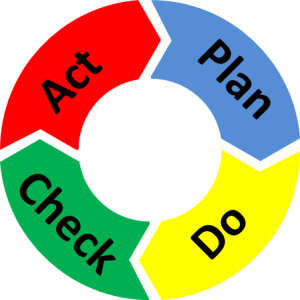

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

Common Mistakes with the PDCA (and Some History)

In my previous post I explained how the PDCA (Plan, Do, Check, Act) should work. However, while most people know the PDCA in theory, I find that the practical implementation is often lacking. And, quite frankly, I am also sometimes sloppy with the PDCA way more often than I would like to admit. Time for some reflection and observation on what works, and why so often it does not.

Hence, in this post I will show common pitfalls and problems when doing a PDCA. Also, simply because it is one of my pet interests, I will also show a bit of the history of the PDCA and its origins in quality control.

The Key to Lean – Plan, Do, Check, Act!

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

In my experience, most lean projects in the Western world fail not because they do not have some detailed tool, but because the PDCA is neglected. Of course, (almost) everybody knows what the PDCA is, but there is a huge difference between knowing the theory and doing it correctly. In this post I will explain in more detail how PDCA should work. In my next posts I will show you the common pitfalls of PDCA, its history, and the many, many different variants of the PDCA that are out there.

The A3 Report – Part 3: Limitations and Common Mistakes

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.

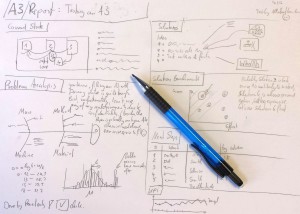

The A3 Report – Part 2: Content

In my last post I wrote about four basic factors for an A3 report (one sheet / A3 size / with pencil / on the shop floor). This week I would like to show you what goes in an A3 report. The important framework here is PDCA (Plan, Do, Check, Act). However, in my view there is no single perfect A3 template that will fit all of your problems. Rather, an A3 is created on the go. Make the tool fit the problem, not the other way round!

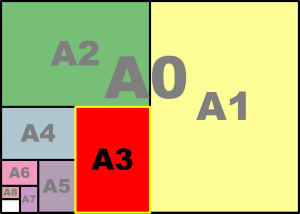

The A3 Report – Part 1: Basics

If you know your way around lean, you surely have hear about the A3 report, famously named after the DIN-A3 paper size. It is also known as the A3 problem-solving sheet. The goal is to get all the necessary data on one sheet of A3 paper using pencil while you are on the shop floor. The A3 report is commonly used for problem solving, but also for project management or status reports.

If you know your way around lean, you surely have hear about the A3 report, famously named after the DIN-A3 paper size. It is also known as the A3 problem-solving sheet. The goal is to get all the necessary data on one sheet of A3 paper using pencil while you are on the shop floor. The A3 report is commonly used for problem solving, but also for project management or status reports.

Lean for Refugees

Europe is currently experiencing a refugee crisis. Hard numbers are difficult to obtain, but it is estimated that one million refugees arrived in Germany in 2015. Government authorities were ill-prepared to handle and organize these people. Significant resources have been put in, but they never seem to be enough. The organizational processes are not yet functioning well.

Europe is currently experiencing a refugee crisis. Hard numbers are difficult to obtain, but it is estimated that one million refugees arrived in Germany in 2015. Government authorities were ill-prepared to handle and organize these people. Significant resources have been put in, but they never seem to be enough. The organizational processes are not yet functioning well.

As it happens, I am an expert in improving organizational and other processes. I decided to help, and together with two other professors, founded an initiative, Lean for Refugees. We are politically neutral, volunteering our time to organize these processes so we can help both the refugees and the government. Let me give you an overview of what we have done so far.