In this third post of my series on the Toyota dashboard we will be looking in more detail at quality. The quality of Japanese car makers in general and Toyota in particular is quite a bit better than the rest of the world’s. After safety, quality is the second-most-important issue at Toyota, definitely before productivity and cost. They do put in quite some effort for tracking quality… and then put in even more effort to fix these issues! Let’s have a look:

In this third post of my series on the Toyota dashboard we will be looking in more detail at quality. The quality of Japanese car makers in general and Toyota in particular is quite a bit better than the rest of the world’s. After safety, quality is the second-most-important issue at Toyota, definitely before productivity and cost. They do put in quite some effort for tracking quality… and then put in even more effort to fix these issues! Let’s have a look:

Quality

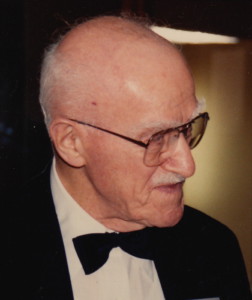

115 Years after the Birth of Joseph Juran

On Christmas Eve 115 years ago, Joseph Moses Juran (December 24, 1904 – February 28, 2008) was born. He was a highly respected and very influential quality guru. His work not only helped the United States, but also changed Japan, possibly even more than that of his better-known colleague Edwards Deming. Time to look back on his life’s impact on the world.

On Christmas Eve 115 years ago, Joseph Moses Juran (December 24, 1904 – February 28, 2008) was born. He was a highly respected and very influential quality guru. His work not only helped the United States, but also changed Japan, possibly even more than that of his better-known colleague Edwards Deming. Time to look back on his life’s impact on the world.

How to Deal With Long Delivery Times

Lean has a bunch of advanced but good tools for material delivery, like Just in Time, Just in Sequence, and Ship to Line. Using them is much easier on short distances and with short delivery times. Yet, sometimes you just don’t have the option of short delivery times. This blog post deals with the issues related to long lead times and delivery times.

Lean has a bunch of advanced but good tools for material delivery, like Just in Time, Just in Sequence, and Ship to Line. Using them is much easier on short distances and with short delivery times. Yet, sometimes you just don’t have the option of short delivery times. This blog post deals with the issues related to long lead times and delivery times.

Pay Attention to Details – Operator Training at Toyota and Scania

Often, implementing “lean” means management is picking the latest lean-related buzzword and telling their people to implement it. This is wrong on so many levels. For one, a lean project should always start with a problem, not a solution. On another level, good manufacturing is all about the nitty-gritty details. Both normal operations and improvement projects need a lot of attention to details. Unfortunately, this is frequently lacking in many companies. In this post I would like to show you the level of detail for operator training in some excellent companies.

The Seven Types of Waste (Muda) – Now with 24 More Types of Waste Absolutely Free!

One popular and well-known concept of the Toyota Production System is the elimination of waste, in Japanese also called muda (無駄). It is one of the three evils of manufacturing systems, the others being unevenness (mura, 斑) and overburden (muri, 無理). In this post I would like to go through the details of waste with you. This includes the traditional seven types of waste – of which I am a big fan. For completeness sake I also included a lot more types of waste I have come across in industry. However, you have to decide yourself if these additional wastes are not themselves a waste.

Corporate Culture on Quality Starts at the Top – A Small Anecdote on Organizational Blindness

Quality starts at the top with management. Top executives like to talk about quality, but employees below usually know very well if the manager only talks the talk or also walks the walk. Words are cheap. Quality (and pretty much everything else that is important) requires attention by management.