Production lines have fluctuations. Sometimes production takes longer, sometimes shorter, than the average. This makes the line balancing tricky. Besides using a simple buffer between workstations, it is also possible to adjust capacity. Other approaches I have written about include the rabbit chase and the bucket brigade. Here I present a variation of the bucket brigade called “One Up One Down.”

Production lines have fluctuations. Sometimes production takes longer, sometimes shorter, than the average. This makes the line balancing tricky. Besides using a simple buffer between workstations, it is also possible to adjust capacity. Other approaches I have written about include the rabbit chase and the bucket brigade. Here I present a variation of the bucket brigade called “One Up One Down.”

Practice

My Workshop Structure for Creative Problem Solving

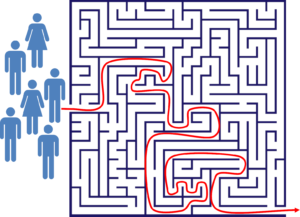

In lean manufacturing – or in fact, in any kind of production system – you have to solve problems. Depending on the problem, you may need a creative solution and have to access the wisdom of the crowd. For this I have a workshop structure that I frequently use for problems that have lots of different options. Let me show you my workshop structure with which I’ve had quite good results.

In lean manufacturing – or in fact, in any kind of production system – you have to solve problems. Depending on the problem, you may need a creative solution and have to access the wisdom of the crowd. For this I have a workshop structure that I frequently use for problems that have lots of different options. Let me show you my workshop structure with which I’ve had quite good results.

Kanban Card Design

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

On the Benefits of a Pencil in Lean

In many lean books and other writing, it is often recommended to use a pencil for certain tasks as, for example, the A3 report. Yet, I have seen very few uses of pencil in lean manufacturing in the Western world. Most of the documents are computer printouts based on Excel, PowerPoint, or Word. The few handwritten documents are usually done in pen (see also my post on The Advantage of Handwritten Data on the Shop Floor).

In this post I will look into why almost nobody uses pencils and why it would be good to use more pencils. I myself am also guilty of that, but I plan indeed to use more pencil in the future.

Pay Attention to Details – Operator Training at Toyota and Scania

Often, implementing “lean” means management is picking the latest lean-related buzzword and telling their people to implement it. This is wrong on so many levels. For one, a lean project should always start with a problem, not a solution. On another level, good manufacturing is all about the nitty-gritty details. Both normal operations and improvement projects need a lot of attention to details. Unfortunately, this is frequently lacking in many companies. In this post I would like to show you the level of detail for operator training in some excellent companies.

Cycle Times for Manual Processes

In my last two posts I described how to measure cycle times. However, for manual processes measuring cycle times is quite different, since the humans that are measured usually strongly dislike being measured. Therefore, it is difficult to measure it directly. There is an alternative to calculate it, but this also has lots of pitfalls. Let me explain you a bit about human psychology, and how to measure manual cycle times.

How to Measure Cycle Times – Part 2

This is the second post on how to measure the cycle time of a process. Again, the cycle time is the fastest repeatable time in which you can produce one part. Hence, as part of a series on manufacturing speed measurements I continue with more details on what cycle times really are. This is the second post on how to measure cycle times (post 1 here), with an additional third post focusing on the details of manual cycle times coming up next.

How to Measure Cycle Times – Part 1

The cycle time of a process is a key to match the supply with the demand in lean manufacturing. Everybody working on a shop floor knows the term. Yet, I still find that people sometimes confuse what exactly it means. The cycle time is the fastest repeatable time in which you can produce one part. Hence, in this post as part of a series on manufacturing speed measurements I would like to dig deeper into what cycle times really are, and how to best measure them. As it turns out, there is actually quite some detail on how to measure cycle times, hence I split this post into two parts (second part How to Measure Cycle Times – Part 2), with an additional third post focusing on the details of manual cycle times.