The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.

The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.

Preceding Factories

One of the key parts of the Industrial Revolution is mechanized and centralized large scale mass production (i.e., a factory). There were factories before the Cromford Cotton Mill. I have written about John Lombe and his silk mill, where a curious tale of industrial espionage helped mechanized silk spinning in England. The Arsenal of Venice could also be seen as a factory, as could the pottery workshops of Josiah Wedgwood. There are more examples. However, the Cromford mill had the largest impact, starting a bonanza of cotton mills in England. Hence, this post will look in more detail at the Cromford Cotton Mill.

Sir Richard Arkwright

Sir Richard Arkwright (23 December 1732 – 3 August 1792) was the son of a Taylor from Preston, Lancashire, England. While initially trained as a barber, he started to improve spinning machines, patenting a spinning frame for making threads in 1769. Arkwright built a cotton mill in Nottingham. However, this mill was powered by horses, which turned out to be rather expensive. Hence, he soon looked for other options using water power.

Establishing the Cromford Cotton Mill

Arkwright found a good spot in Cromford. An old Roman lead mine drainage channel provided water year round, even in the coldest of winter. The village was also isolated and hence away from trouble and spies. Still a major trade route passed through the village, which would help with sending and receiving materials.

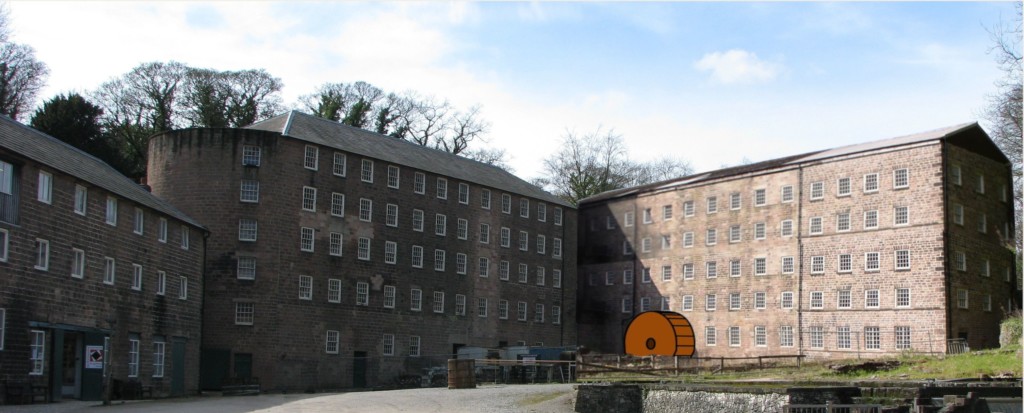

Arkwright leased the property on August 1, 1771, and started construction immediately. He even bought a house and had it pulled down to get raw materials for building his mill. The mill started producing cotton yarn in 1772, making this year the 250th anniversary of the Cromford Cotton Mill.

Second Mill

The mill was a huge success. Arkwright was able to produce cotton yarn much cheaper and faster than anybody before. Thus he built a second mill in 1775. This mill was even larger than the first one, with seven floors of 325 square meters each.

Managing the Workforce

Like all larger employers at his time, Arkwright had difficulties managing his workforce. However, he was considered a good employer, providing schooling and housing. His salaries were somewhat larger than average, and he tried to avoid violence in managing his workforce.

Highly uncommon for the time, the mill was heated and each floor had a toilet. However, this may have been more in consideration for the cotton, which is easier to process at warmer temperatures, and toilets on each floor reduced the absence of the workers when they needed to go.

Nevertheless, the workers were not always truly motivated, and were often more interested in their ale rather than their work. This was somewhat understandable, as the twelve-hour shifts were quite long (although, again, not uncommon for its time).

Influence of the Mill

The mill was an enormous success, and hence was hugely influential. While his water-frame spinning machine was still protected by his patents, Arkwright himself built a flurry of mills nearby, including Birkacre Mill at Chorley, Haarlem Mill in Wirksworth, and Masson Mill in Matlock Bath.

Once his copyright expired, many others in England started to build their own mills. Samuel Slater brought the technology to the USA, and Gottfried Brügelmann to Germany—both of course in violation of British intellectual property protection.

Backlash

The weavers in Britain were very much against the mechanized competition, which was able to produce yarn (and later cloth) both cheaper and better. The Luddite movement destroyed multiple mills, including Arkwright’s Birkacre mill in 1779. In response, Arkwright armed up, and even had a cannon installed at the Cromford mill. The mill from the outside also looks more like a fortress than a factory. However, the mill breakers never even got close to Cromford, and the mill escaped unharmed.

Decline and End

Richard Arkwright died very wealthy in 1792. His son Richard Arkwright Jr. took over the business, and became the richest man in Europe. Unfortunately, the lead mines from which the water came to the mills were deepened, and the water flow was reduced. The mills were never running at full capacity again. In 1850 the Cromford mill was closed. The second mill burned down to the ground in 1890. The first mill burned in 1930, and lost its top two floors. The mill is now a UNESCO world heritage location, but when I visited it it felt somewhat underwhelming for the significance of the mill. Much of the mill is still empty, and other parts have an assortment of random businesses from a software developer to a stop-smoking center.

Still, I am very impressed with the mill and its historic significance. If you ever happen to be in the area (between Sheffield and Birmingham), check it out, and maybe even some of the other mills from this bonanza of cotton mills. For me, this is one of the first milestones of the Industrial Revolution. It is also an important part of my book in the history of manufacturing – for which I am preparing a revised version to be published next year (however, I have to get the rights back from my publisher first). In any case, I will definitely let you know once it is out. Now, go out, make whatever you are producing even more efficient, and organize your industry!

Thank you for the history.

Very interesting. Thanks