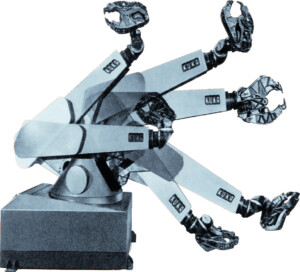

Fifty years ago, the FAMULUS industrial robot was introduced by the German machine tool maker KUKA. This articulate-arm kinematics industrial robot with six axes was the first of many modern industrial robots. This design is nowadays still the most common type of industrial robot.

Fifty years ago, the FAMULUS industrial robot was introduced by the German machine tool maker KUKA. This articulate-arm kinematics industrial robot with six axes was the first of many modern industrial robots. This design is nowadays still the most common type of industrial robot.

Pre-industrial Robots

The idea of machines doing manual labor is quite old. Different gadgets were built by tinkerers in Europe and Asia, as for example mechanical dolls in Japan or the automata by Jaquet Droz. But these were clunky, and served little more than being a curiosity. Some, like the mechanical turk, were fakes, with a person hidden inside.

The word robot comes from the Czech language and means serf labor. The Czech writer Karel Čapek used the term in 1920 for a science fiction story in which robots were artificially created biological servants, which was later picked up by the more famous author Isaac Asimov.

The first robots in a more modern sense and powered by electricity appeared in America in the 1960s. The Rancho Arm was an artificial limb developed by the Rancho Los Amigos Hospital in California in 1963. MIT developed its own arm in 1968, with the most unfortunate name tentacle arm. The Stanford Arm from—you guessed it—Stanford University was built in 1969. All of these were interesting, but had limited actual use.

The First Industrial Robot: Unimate

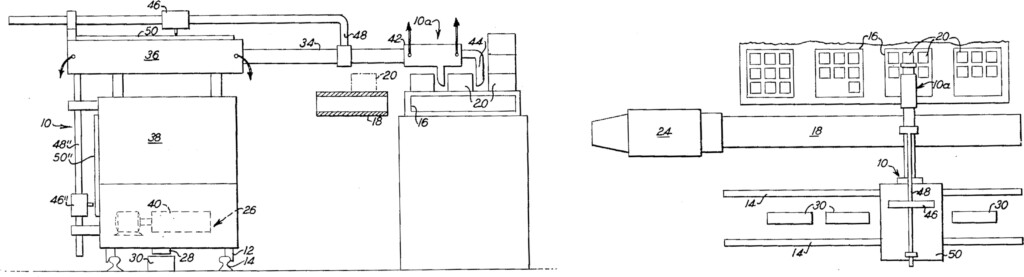

The first robot actually used in industry was the Unimate. The concept was patented by George Devol from Kentucky in 1954 as a programmed article transfer. This robotic arm was powered by hydraulics and controlled by a computer. However, this robot did not really look like a modern robot, but more like a crane on rails. Together with his partner, Joseph Engelberger, they secured funding for their startup, Unimation, established in 1956.

Starting with their idea, they developed a working product, the first industrial robot, UNIMATE. Their first sale was in 1960 to GM, where it started working on an assembly line at the Inland Fisher Guide Plant in Ewing Township, New Jersey, in 1961. The robot lifted hot castings, quenched them, and passed them on to the next machine. Since this was a potentially risky task, the robot helped to improve the safety of the workers. While this robot looked more evolved than the 1954 patent drawing, its kinematics is rare nowadays. Nevertheless, the robot did its job for many years before retiring to a museum. Its company, Unimation, however, had more difficulties and turned its first profit only in 1975. The company was purchased by Westinghouse in 1984, and since 1988 is part of the Swiss company Stäubli.

The KUKA FAMULUS

Around 1970, Europe and especially Germany overtook the US in terms of digital technology for industry. German CNC machines became widespread. Both ABB and KUKA started to develop robots. KUKA was founded in 1898 as Keller und Knappich Augsburg in Germany, producing acetylene, welding apparatus, household appliances, automobile headlights, and more.

Around 1970, Europe and especially Germany overtook the US in terms of digital technology for industry. German CNC machines became widespread. Both ABB and KUKA started to develop robots. KUKA was founded in 1898 as Keller und Knappich Augsburg in Germany, producing acetylene, welding apparatus, household appliances, automobile headlights, and more.

Around 1970 KUKA decided to develop robots. However, instead of the Unimate design, they decided on an articulate arm. Fifty years ago, in 1973, KUKA introduced their first robot, the KUKA FAMULUS. It was the first articulated robot with six axes, a design that is now probably the most common kinematic for industrial robots. The robot was versatile and had a much greater range and flexibility of motion than previous robots. It could be used for a wide range of tasks. Hence, it was a smashing success and turned KUKA into the robotics company it is nowadays. (Note: The Americans prefer to start the history of industrial robots with their American Unimate rather than the German FAMULUS, which is also a possible way of seeing history. Both were major steps in an evolution of robotics that is still ongoing).

A Robotic Boom

Many other companies followed, using this articulate robot design. Only one year later in 1974, ASEA (now ABB) presented their own IRB6 robot with an internal microprocessor. The first two IRB 6 robots were sold to Magnusson in Sweden for grinding and polishing pipe bends and were installed in production in January 1974. In Japan, both Yaskawa Denki and FANUC also started producing robots in 1974. It took America a bit longer to catch up on the new design, and Unimation presented their articulate arm robot PUMA only in 1978. Other companies that started to build industrial robots were General Electric, General Motors (in a joint venture with FANUC), Automatix, and Adept Technology. However, not many companies survived, and nowadays the center of industrial robot making is Japan and Europe.

New Kinematics

New kinematics were developed that are also still very popular. The SCARA (Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm… but nobody remembers that) was created as a prototype in 1978 by Professor Hiroshi Makino at Yamanashi University in Japan. It was introduced to the market in 1981 and is particularly well suited for picking and placing while being both compact and inexpensive due to having only four axes.

The Delta robot was developed by Prof. Reymond Clavel at the École Polytechnique Fédérale de Lausanne in Switzerland. It was patented in 1987. This robot has all actuators in the base and very thin arms, which gives it a LOT of speed and make it well suited for picking and placing.

Software over Hardware

Industrial robots continue to evolve. However, since around 2000, the software of these robots became more important than the hardware. Through better sensors the machines have a better understanding of their environment, and much effort is put into the software to make use of this data. Cobots are already in use, where humans can work together with robots without a safety cage for the machines. This is achieved through the use of intelligent software (but also usually by using low-power robots that can’t hurt people if they go awry).

One challenge that is worked on is gripping items that could have a multitude of shapes and behaviors, for example the Amazon Picking and Stowing needs (also called End of arm tooling). Another challenge is to smoothly hand items from the robot to a human and back, which currently is still quite awkward. In the long run, artificial intelligence may make the robot intelligent enough to recognize the task on hand on its own without detailed programming. Other countries, especially China, are also putting a lot of effort into developing their robotics industries (and have also bought KUKA, much to the chagrin of Germany). If you are in manufacturing, chances are that robots are important in your business. Now, go out, get a good trade-off between automation and human work, and organize your industry!

Disclaimer: A long time ago, during my undergraduate studies I worked at KUKA, writing my thesis on their robots. As such, I like the company, and was sad to see it sold to China.

PS: Images of KUKA robots copyright KUKA Group with permission.

Informative article on the evolution of Robots!

Good to read this article. By the way, maybe KUKA may become better after sold to China.