In my last three posts I showed you how I look at shop floors, starting with some general guidance (FOCUS!) and going into detail through the different aspects of what I try to observe on the shop floor (5S, visual management, waste, unevenness, overburden, and safety). This usually gives me a reasonable overview of what is going on on the shop floor. However, this is not all I do. For projects, I may have project specific observations (e.g., when I do a SMED project, I observe in detail the actual changeover). But beyond that, there is another source: the available data! Hence, this post will compare information you observed yourself on the shop floor (the gemba) vs. data obtained by others or by computers.

In my last three posts I showed you how I look at shop floors, starting with some general guidance (FOCUS!) and going into detail through the different aspects of what I try to observe on the shop floor (5S, visual management, waste, unevenness, overburden, and safety). This usually gives me a reasonable overview of what is going on on the shop floor. However, this is not all I do. For projects, I may have project specific observations (e.g., when I do a SMED project, I observe in detail the actual changeover). But beyond that, there is another source: the available data! Hence, this post will compare information you observed yourself on the shop floor (the gemba) vs. data obtained by others or by computers.

Gemba vs. Data

So far my blog posts talked about actual observations on the shop floor (in Japanese, gemba). But there is also information that other people or automated systems gathered, either on paper or in digital form (or, less commonly, other data like production samples). Let’s call this data (even though what you do on the shop floor is also to gather data). So when should you use what?

In lean, the mantra is clear: Gemba! Gemba! Gemba! But in reality, it is not that simple. Both gemba and data have their place. The never-ending promotion of gemba is more to the fact that everybody uses data a lot anyway, and you don’t need to tell people to stop going to the shop floor so you can look at data instead. They are doing that anyway, and too much.

Advantages of Gemba

There are quite a few advantages of looking at things yourself on the shop floor (gemba). First, it gives you much more information than a data set. While data can express a lot, it is not so good for softer but still important impressions on the shop floor. For example, it is hard to measure cleanliness. Similarly, the mood of the employees is best observed on the shop floor with the employees.

There are quite a few advantages of looking at things yourself on the shop floor (gemba). First, it gives you much more information than a data set. While data can express a lot, it is not so good for softer but still important impressions on the shop floor. For example, it is hard to measure cleanliness. Similarly, the mood of the employees is best observed on the shop floor with the employees.

Second, and related to the first, you can always dig deeper. If you have only data, and you find out that you need more data on a certain situation, you have to wait until the data is collected and analyzed. On the shop floor, however, you can always dig deeper. If you find that one machine is broken down, go there and find out why. If you find out that material is piling up, go downstream and find out why. If material is missing, go upstream and find out why. Let your inner Sherlock Holmes come out and keep on digging until you find the root cause.

Observations on the gemba are also real time. Depending on how you collect data, there may be quite a bit of delay. On the shop floor, it happens right in front of your eyes. And finally, observing on the shop floor shows presence. A manager who is never on the shop floor loses his standing on the shop floor. It also gives the employees the opportunity to talk with you and show you issues on the shop floor that may have otherwise been missed. This communication is ideally bidirectional, and you can also ask them questions too!

Observations on the gemba are also real time. Depending on how you collect data, there may be quite a bit of delay. On the shop floor, it happens right in front of your eyes. And finally, observing on the shop floor shows presence. A manager who is never on the shop floor loses his standing on the shop floor. It also gives the employees the opportunity to talk with you and show you issues on the shop floor that may have otherwise been missed. This communication is ideally bidirectional, and you can also ask them questions too!

Observing data on the shop floor also makes it much harder to fudge. While it is possible, it is not easy to make a shop floor look better than it really is. On a PowerPoint slide or an Excel table, however, it is very easy to misrepresent numbers or ignore inconvenient data. I have a whole post on Visit the Shop Floor or Your People Will Fool You! – Genchi Genbutsu.

Advantages of Data

There are also advantages to using data. The disadvantages of the shop floor are merely the opposite of the data advantages, and vice versa.

One of the biggest advantages of data is that obtaining the data can often be outsourced. Rather than having a highly paid manager spend his time collecting data, it can be collected by a computer system, or by a (less expensive) operator on the shop floor. Hence, using available data saves time for leadership. In many cases, the data is already available since it is recorded anyway. But even if it is not your effort, it is an effort, and it is quite possible to handicap a shop floor by having excessive data requirements (I have seen that!).

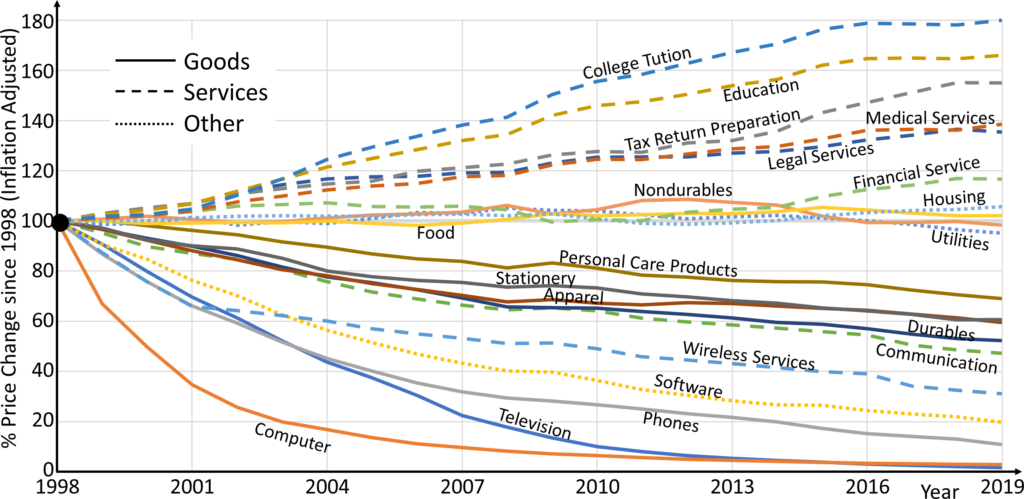

Another big advantage is that data often includes historical data. This makes it a lot easier to see trends, which in turn makes it a lot easier to counteract a worrisome trend before it becomes a problem. Charts and diagrams can really help here!

Available data is also often in numerical or generally quantitative form, whereas observations on the shop floor are often (but not always) more qualitative. Having numbers makes it a lot easier to generate other numbers out of them. If both the data and the model that uses the data is good (and that is sometimes a BIG “if”), you can learn more and dig deeper to understand your shop floor and the root causes for its behavior. Things like regression analysis or AI to find the relevant variables or levers to influence your system are usually only possible with data. Or even simple things like quality are hard to observe directly on the shop floor. If your failure rate is measured in PPM (parts per million), then you rarely see a defect on the shop floor (even if you know what to look for). Even if you see a defect, it gives you no information on the frequency of the defects.

To properly understand your production system, you need to observe the gemba yourself, and then augment these observations with data that is either available or is collected over time subsequently. Naturally, this data also comes from the shop floor, but it goes through often multiple hands and is processed and cleaned before you see it. Hence, data does have its advantages, too, IF the data is good and IF you understand what the data is trying to tell you. But more on this in the next post. Now, go out, make sure you have the data you need AND that the data is good, and organize your industry!